- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220-380

-

Place of Origin:

-

China

-

Brand Name:

-

proman

-

Weight:

-

22000 KG

-

Product name:

-

drinking water filling machine

-

Function:

-

Bottle Washing Filling Capping

-

Control:

-

Servo Motor drinking water filling machine

-

Filling speed:

-

1000-6000 Bottles

-

Feature:

-

High Precision Filling Level

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Keywords:

-

drinking water filling machine

-

After Warranty Service:

-

Video technical support

-

Suitable for:

-

bottle water

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

220-380

-

Place of Origin:

-

China

-

Brand Name:

-

proman

-

Weight:

-

22000 KG

-

Product name:

-

drinking water filling machine

-

Function:

-

Bottle Washing Filling Capping

-

Control:

-

Servo Motor drinking water filling machine

-

Filling speed:

-

1000-6000 Bottles

-

Feature:

-

High Precision Filling Level

-

Usage:

-

Beverage Filling Packaging

-

Bottle type:

-

PET Plastic Bottle

-

Keywords:

-

drinking water filling machine

-

After Warranty Service:

-

Video technical support

-

Suitable for:

-

bottle water

Product Description

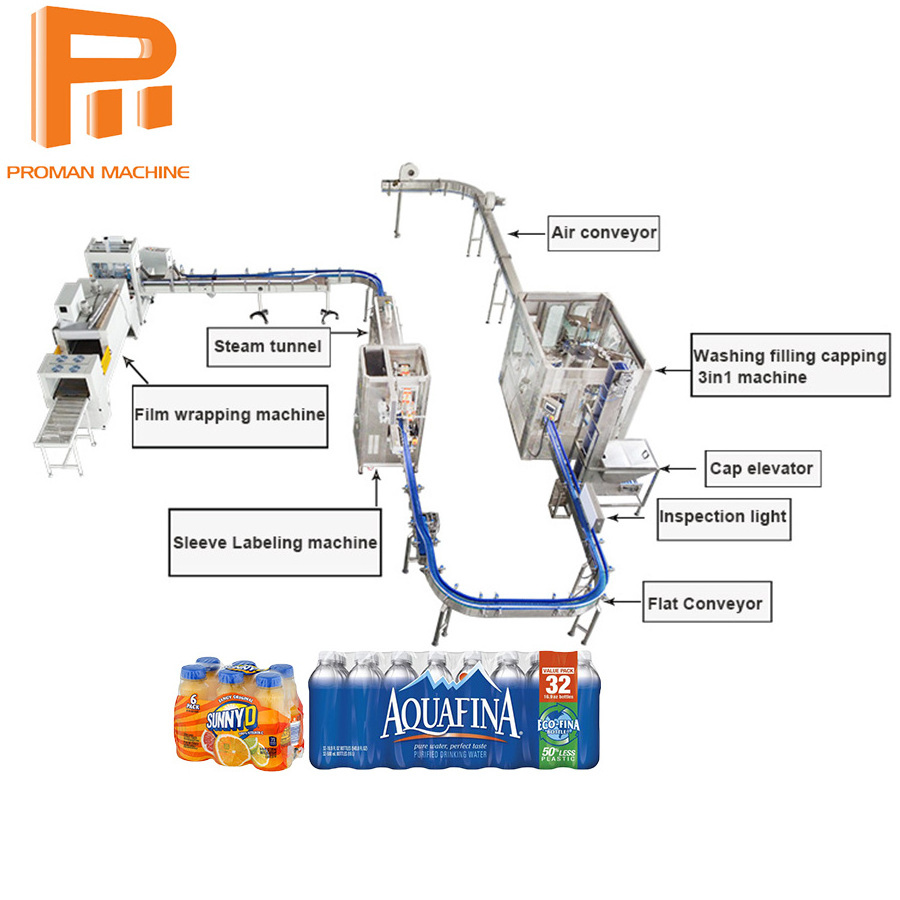

Professional Supplier 3000bph Complete Mineral Pure Water Juice Soda Beverage Bottling Machine

water filling machine

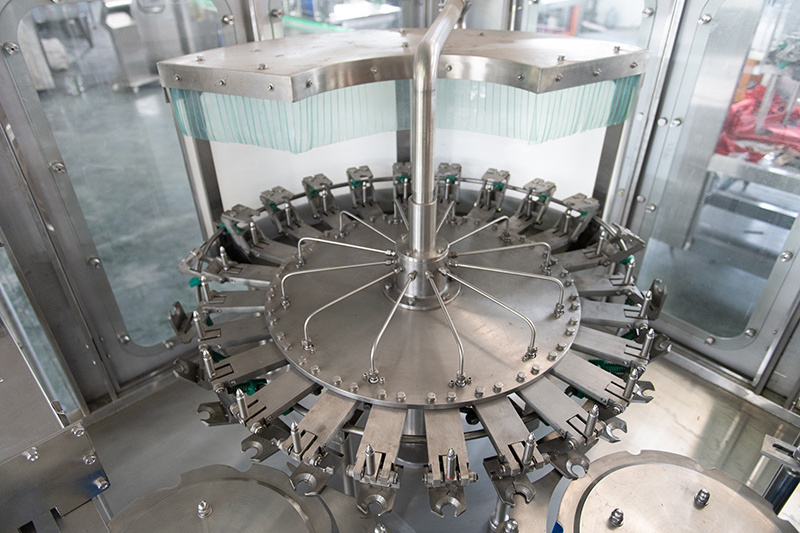

The monobloc machine is integrated with rinsing, filling and capping together:

3-in-1 filling machine, combined with rinsing, filling and capping. It is innovated and designed in the requirement of still pure water and mineral water, on the bases of introducing, digesting and absorbing advanced technology from Germany and Italy.

Different models can satisfy various requirement of output from 2000B/H to 24000B/H.

The whole process is automatic ,suitable for PET bottle ,plastic bottle filling mineral water and pure water/juice/csd beverage.

Filling way using the gravity or micro pressure filling ,make the speed faster and more stable ,so compared with the same model our machine output is higher and more efficient.

The machine adopts advanced Mitsubishi programmable controller(PLC) to control the machine adopts advanced automatically, interworking with inverter with inverter running more stable and reliable the photoelectric sensor detect all part running state with high degree of automation, easoperation.

The whole process is automatic ,suitable for PET bottle ,plastic bottle filling mineral water and pure water/juice/csd beverage.

Filling way using the gravity or micro pressure filling ,make the speed faster and more stable ,so compared with the same model our machine output is higher and more efficient.

The machine adopts advanced Mitsubishi programmable controller(PLC) to control the machine adopts advanced automatically, interworking with inverter with inverter running more stable and reliable the photoelectric sensor detect all part running state with high degree of automation, easoperation.

Technical parameter

drinking water filling machin e

| Model | CGF14-12-4 | CGF16-16-5 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 |

| Capacity(500ML) | 4000BPH | 6000BPH | 8000BPH | 12000BPH | 15000BPH | 18000BPH |

| Washing Heads | 14 | 16 | 18 | 24 | 32 | 40 |

| Filling Heads | 12 | 16 | 18 | 24 | 32 | 40 |

| Capping Heads | 4 | 5 | 6 | 8 | 10 | 12 |

| Suitable Bottle | PET Bottle ,Plastic Bottle | |||||

| Diameter of bottle | Diameter: 55-110 MM | |||||

| Height Of Bottle | 150-310MM | |||||

| Suitable Cap | Plastic Screw Cap | |||||

| Weight | 1500kg | 2000kg | 4000kg | 4500kg | 6000kg | 7800kg |

| Main Motor Power | 1.2kw | 1.5kw | 3kw | 3kw | 3kw | 5.5kw |

Washing Head:

-

Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

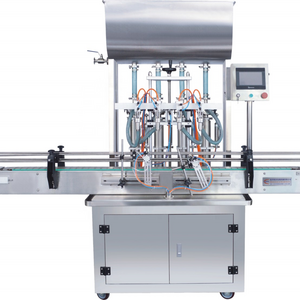

Filling Head:

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

Capping Head:

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Advantages

:

1. Washing , Filling ,Capping ,finish by the one machine---------

Save much space and more sanitary.

2. Application of advanced bottle conveying technology - bottle neck clamping and bottle suspending technology---------- Convenient to change different bottles .

3. Advanced programmable PLC and touch screen-------- Easy to operate.

4. All electronic components and pneumatic elements------- From famous international enterprises.

5. All spare parts that may touch with water ------- From high-quality stainless steel.

2. Application of advanced bottle conveying technology - bottle neck clamping and bottle suspending technology---------- Convenient to change different bottles .

3. Advanced programmable PLC and touch screen-------- Easy to operate.

4. All electronic components and pneumatic elements------- From famous international enterprises.

5. All spare parts that may touch with water ------- From high-quality stainless steel.

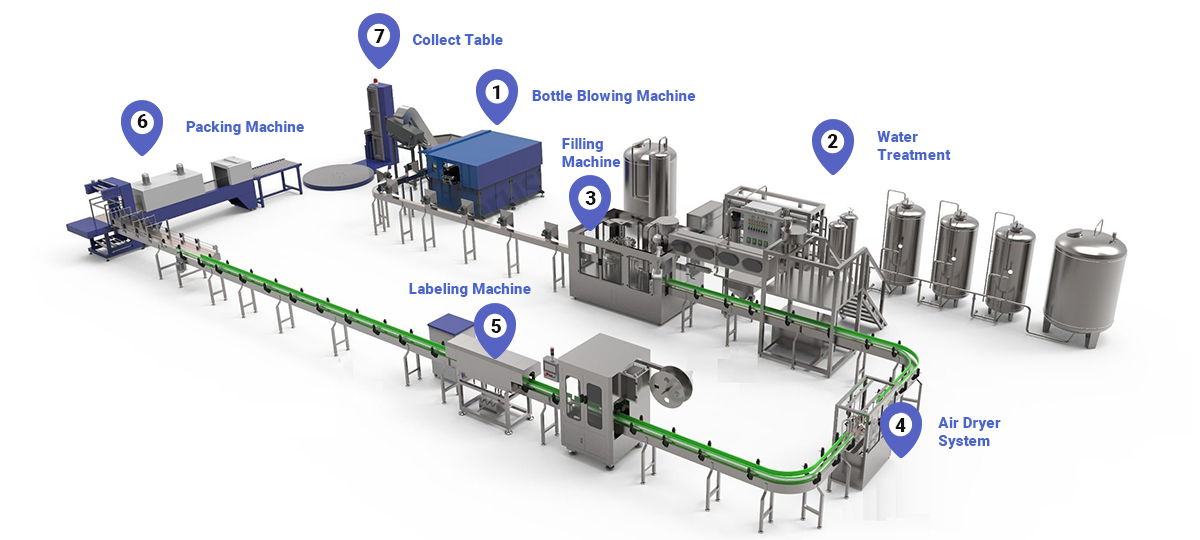

Flow Chart:

| Machines | Functions |

| 1.Water Treatment System | Raw water pump---sand filter--active carbon---precision filter--high pressure pump---RO--UV sterilizer--water tank |

| 2.Water Filling Machine | Washing,Filling,Capping 3 In 1 Machine |

| 3.Bottle Labeling Machine | Put Labels on the bottles, label type: PVC, PET. |

| 4.Ink Jet Printer/Code Sprayer | Printing production date in bottle |

| 5.Bottle Packing Machine | Group Bottle like:24=4*6 ,12=3*4 6=2*3 |

Hot Searches