- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Model Number:

-

pvc marble sheet

-

Sample Service:

-

Only send a small sample about 10*15cm

-

Proportion:

-

50(g/cm3)

-

Flexural Strength:

-

5(MPA)

-

Usage:

-

wall decoration

-

Packing:

-

PE Bag/Wooden Pallet

-

Composition:

-

30% pvc, 67% CaCO3, 3% additive

-

Compressive Strength::

-

4(MPA)

-

Surface Finished:

-

UV Coating

-

Product name:

-

PVC Marble Sheet

-

Material:

-

PVC, PVC Board + Marble/Wood Design + UV Coating+PE Protective Film

Quick Details

-

Project Solution Capability:

-

graphic design

-

Application:

-

Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

China

-

Model Number:

-

pvc marble sheet

-

Sample Service:

-

Only send a small sample about 10*15cm

-

Proportion:

-

50(g/cm3)

-

Flexural Strength:

-

5(MPA)

-

Usage:

-

wall decoration

-

Packing:

-

PE Bag/Wooden Pallet

-

Composition:

-

30% pvc, 67% CaCO3, 3% additive

-

Compressive Strength::

-

4(MPA)

-

Surface Finished:

-

UV Coating

-

Product name:

-

PVC Marble Sheet

-

Material:

-

PVC, PVC Board + Marble/Wood Design + UV Coating+PE Protective Film

Products Description

|

Size

|

1220*2440mm/1220*2800mm/1220*3000/More sizes pls contact us

|

|

Thickness

|

2.5mm/2.8mm/3mm/3.5mm/4mm/More thickness pls contact us

|

|

Name

|

PVC UV Marble Sheet (SPC Sheet)

|

|

Density

|

2.0g/cm3=200kg/m3

|

|

Material

|

40% PVC + 58% Calcium carbonate + 2% others

|

|

Surface

|

Hot stamping & uv coating

|

|

Structure

|

PVC rigid board+marble design+UV coated+PE protective film

|

|

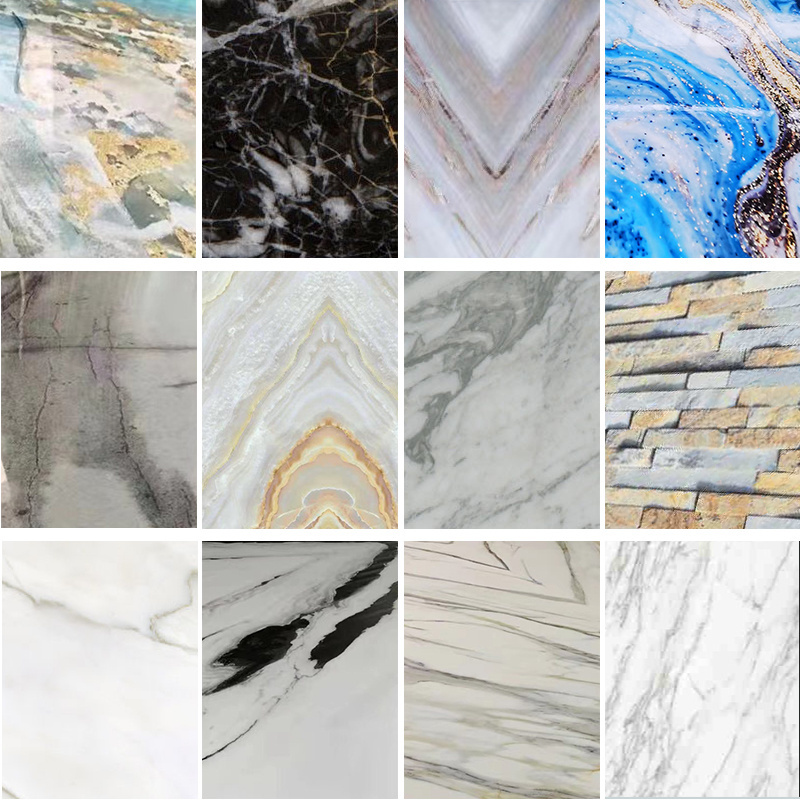

Designs

|

Marble grain, wood grain, solid and 3D

|

|

Application

|

Interior decoration for commercial and residential places.

|

|

Installation

|

Glued on the wall/Aluminum trim profile/Sealant installation

|

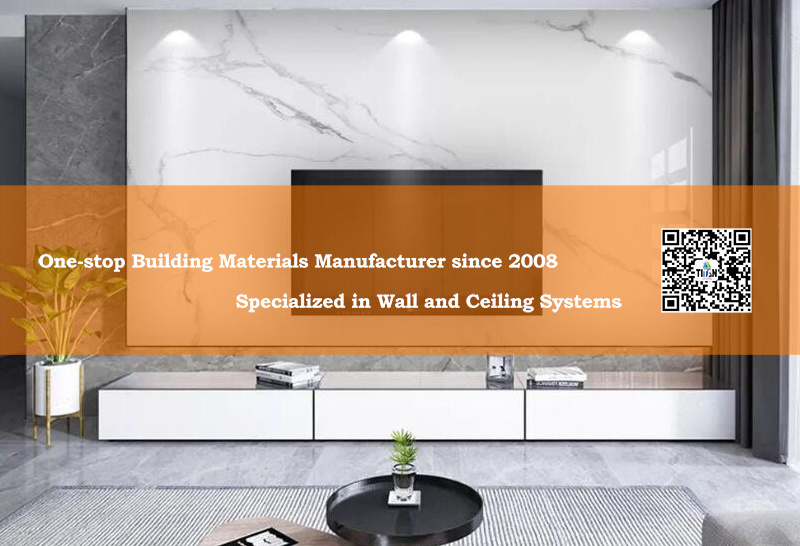

UV Marble Sheet

UV Marble Sheet is a 'Ultraviolet' looking sheet which gives a sophisticated and simple look to interior. It is suitable for most building applications for fitting in floors.PVC marble sheet is also called PVC sheet, PVC marble, PVC marble sheet. It is mainly made of stone powder (calcium carbonate powder) and plastic (PVC resin), so technically it should be called Stone Plastic Composite Marble Sheet, SPC Marble Sheet, or SPC Marble Sheet for short.

Main Characteristic

1. Easy to clean, cut and install (use glue is ok, no more nails glue); Glossy; Formaldehyde-free; No radiation

2. Instead of natural marble, but weight is only one fifth of the natural marble, and price is just one tenth of the natural marble.

2. Instead of natural marble, but weight is only one fifth of the natural marble, and price is just one tenth of the natural marble.

3. 100% water-resistant, fungus-resistant, corrosion-resistant,termite-resistant, etc.

4.Widely used in living room, kitchen, washing room, bedrooms. kitchen rooms, schools, hotels, factories, etc .

4.Widely used in living room, kitchen, washing room, bedrooms. kitchen rooms, schools, hotels, factories, etc .

Have good flame retardant performance

Scratch resistance, wear resistance and dirt resistance

Moisture-proof & anti-corrosion

High definition printing clear lifelike texture pattern

High brightness surface smooth

High toughness and good formula can be bent

Color Display

Installation

How to Install UV Marble Board

①

The bottom layer of the confimation and clean the bottom to be fully dry,so that the bottom level.Remove dirt and rubbish.The bottom layer,please use the gypsum board or the magnesium plate and the surface smooth and waterproof material plate.

②

Marking and Positioning

In accordance with the size of the decoration,the shape of the bottom line,positioning.

③ Double side tape adhesive bonding tape at the tixed position,hard pressed to make its cement.

Usage:the wall is about 3.3/m2 of the ceiling is about 4.3/m2.

④ Adhesive glue

Cut the hose glue bottle mouth,leaving the cigarette weight(about 7mm) the width of the exit,and then squeeze the glue,(tape beside the position in the adhesive glue into a wire bound usage on the wall about 0.5 A/m2 the ceiling about 0.6A/m2.

⑤ Double sided adhesive tape for the removal of the adhesive tape Stripping,remove the Separation of paper.

⑥ In 10 minutes after the bonding of the decorative plate,the decoration plate is bonded to the fixed position.The position of the hands to press the tape,to make it fully bonded.Please note that you can not move or re-bond.

⑦ Maintenace of 1 days during the course of the adhesive glue.

③ Double side tape adhesive bonding tape at the tixed position,hard pressed to make its cement.

Usage:the wall is about 3.3/m2 of the ceiling is about 4.3/m2.

④ Adhesive glue

Cut the hose glue bottle mouth,leaving the cigarette weight(about 7mm) the width of the exit,and then squeeze the glue,(tape beside the position in the adhesive glue into a wire bound usage on the wall about 0.5 A/m2 the ceiling about 0.6A/m2.

⑤ Double sided adhesive tape for the removal of the adhesive tape Stripping,remove the Separation of paper.

⑥ In 10 minutes after the bonding of the decorative plate,the decoration plate is bonded to the fixed position.The position of the hands to press the tape,to make it fully bonded.Please note that you can not move or re-bond.

⑦ Maintenace of 1 days during the course of the adhesive glue.

Recommend Products

Application

Product packaging

Hot Searches