Name: Vibratory Finishing Machine

Code: XXZP-AB400X

Brand: Xingxing

Original: Zhejiang, China

1. CE certified vibratory finishing machine.

2. Stress relief welding required, h eavy duty structure design.

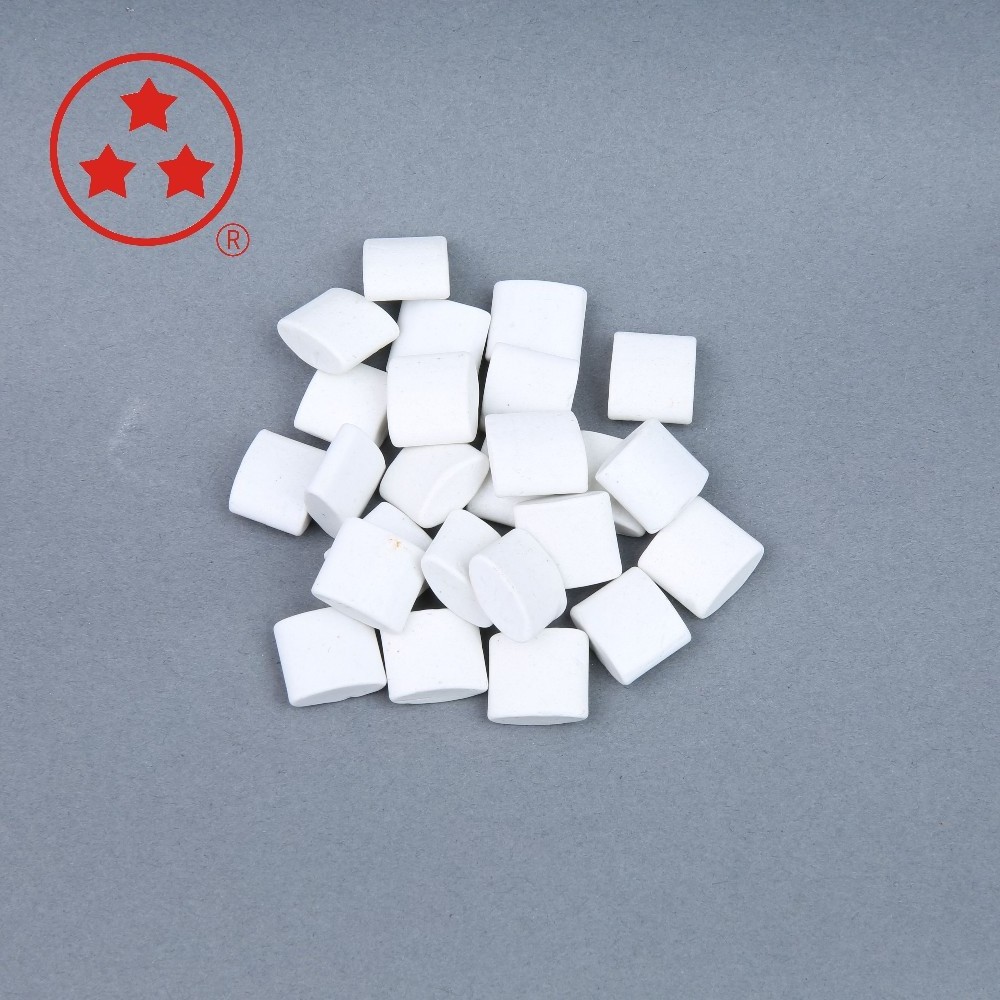

3. Adoption of vibratory motor to produce vibratory force, it makes workparts and medias move in one direction and mass finished interactively in the processing vessel to accomplish the surface improvement.

4. With independent control panel available, control panel with different function design options.