- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

800-1000m2

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HTX

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7000*1000*1800

-

Weight:

-

2000 kg, 2000KG

-

Product name:

-

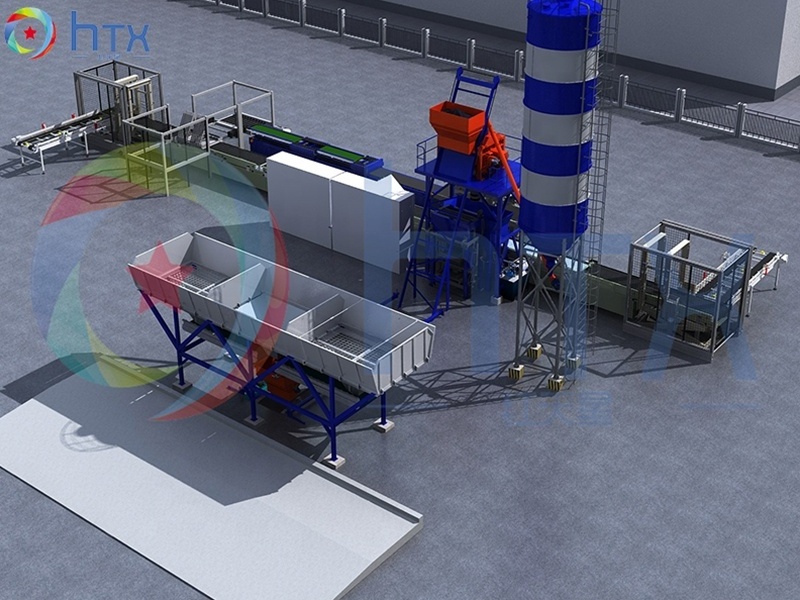

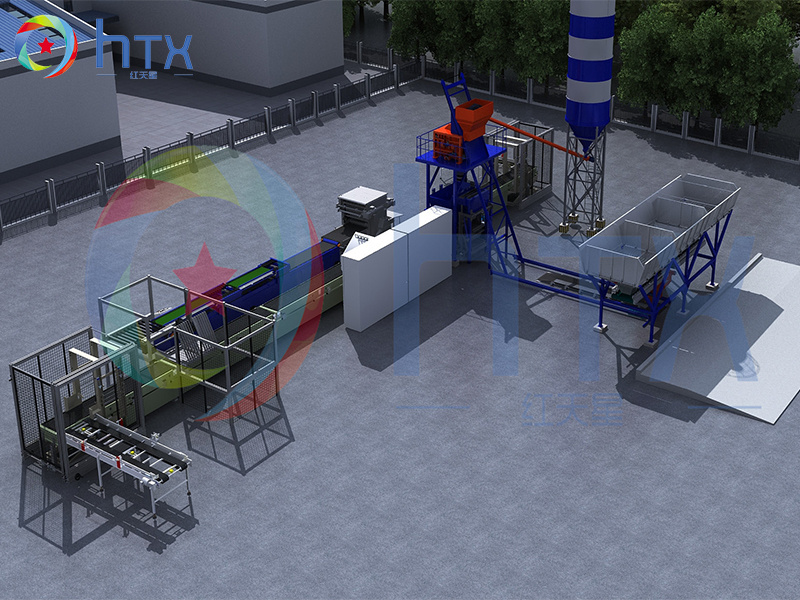

Dosing Wet Mix Concrete Batching Plant Controller System

-

Size:

-

7000*1000*1800

-

Color:

-

Blue

-

Style:

-

Full Auto

-

Material:

-

Steel

-

Function:

-

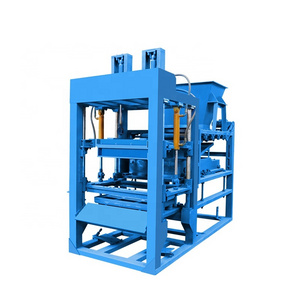

Producing Artificial Stone

-

Stone Form:

-

Wall Brick

-

Feature:

-

High Productivity

-

MOQ:

-

1 Set

Quick Details

-

Type:

-

Production line

-

Power:

-

12.7KW

-

Cutting thickness (max):

-

50mm

-

Production Capacity:

-

800-1000m2

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HTX

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

7000*1000*1800

-

Weight:

-

2000 kg, 2000KG

-

Product name:

-

Dosing Wet Mix Concrete Batching Plant Controller System

-

Size:

-

7000*1000*1800

-

Color:

-

Blue

-

Style:

-

Full Auto

-

Material:

-

Steel

-

Function:

-

Producing Artificial Stone

-

Stone Form:

-

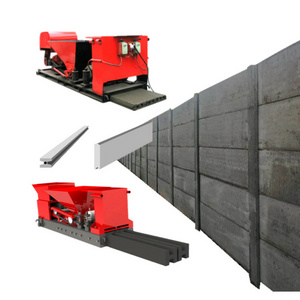

Wall Brick

-

Feature:

-

High Productivity

-

MOQ:

-

1 Set

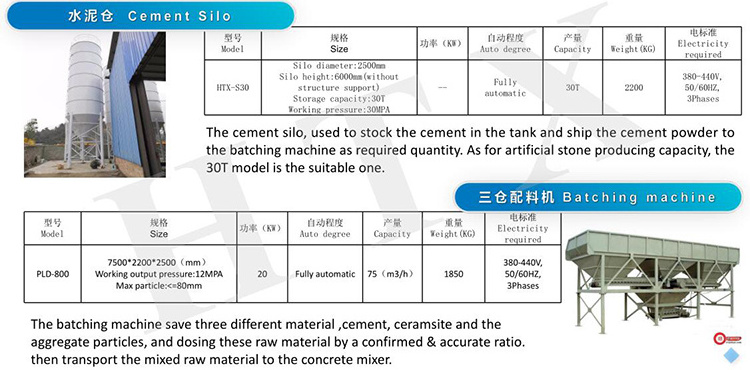

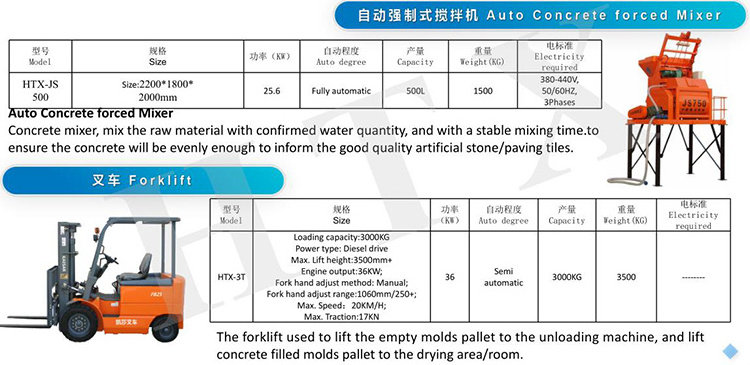

automatic wet concrete cast dosing machine

2. Labors saving for production, 5-6 workers needed only, can largely reduce the labor cost of factory output.

3. Multiple function for production, it include unloading, painting, concrete dosing and stacking, and available usage for plastic molds of floor tile and terrazzo tile, silicone molds for artificial stone etc.

4. The auto spray painting machine, has function for mold oil painting, stroll color painting and full color painting, also it can be turned on/off separately.

|

Name |

Model |

Specification |

Size (mm) |

Power (Kw) |

Capacity (m2/day) |

Weight (Kg) |

|

Artificial stone production line |

HTX-P-01 |

Hydraulic driving;Auto feeding; vibrating and timing feeding |

7000*1000*1800 |

12.7 |

800-1000 |

2000 |

|

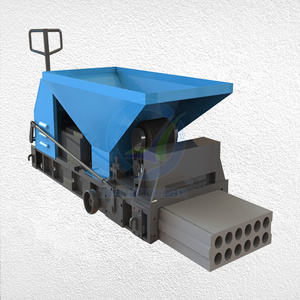

Artificial stone production line |

HTX-P-02 |

Chain drived;Auto feeding,auto vibration |

8000*1100*1600 |

4.05 |

600-800 |

1500 |

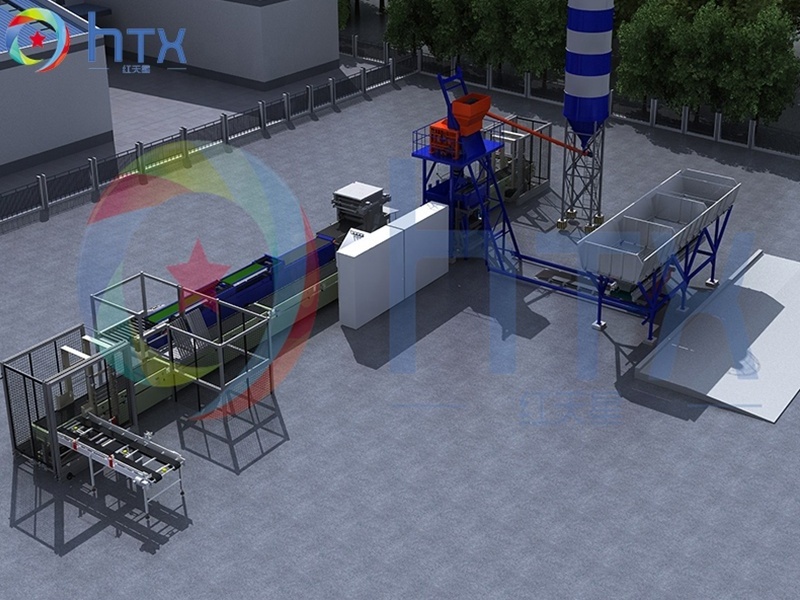

1.More efficient production,can achieve 800M2 Per day(8hrs)

2.Labors saving for production,5-6 workers needed only,can largely reduce the labor cost of factory output.

3.Multiple function for production,it include unloading,painting ,concrete dosing and stacking ,and available usage for plastic molds of floor tile and terrazzo tile,silicone molds for artificial stone etc.

4.The auto spray painting machine,has function for mold oil painting,stroll color painting and full color painting,also it can be turned on/off separately.