- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Box Culvert

-

Design Style:

-

Modern

-

Type:

-

6061-T6

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GETO

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Free spare parts

-

Project Solution Capability:

-

graphic design, 3D model design, Cross Categories Consolidation

-

Application:

-

Box Culvert

-

Design Style:

-

Modern

-

Type:

-

6061-T6

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GETO

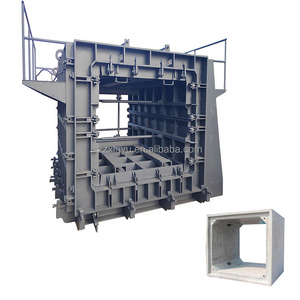

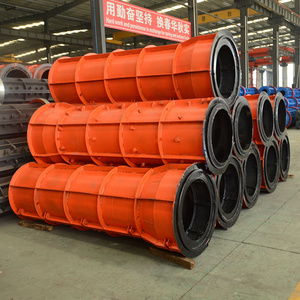

The concept of this product utilization is to form each room of the properties as one modular unit, with the formation of its structure and renovation done in a precast factory, in advance of transportation to the site for on-the-spot assembly.

PPVC precast housing molds realize the whole prefabricated room through one-time casting and molding. This innovation can effectively increase the working efficiency on site and minimize construction labor costs.

Advantage(1):High Construction Efficiency, Fast Finished Product

Housing precast formwork can form all structures of a building,including deck, side wall, base floor, door opening

and window at one time, thus minimizing duration for the precast structure formation. Compared with the traditional

steel formwork, it has over 50% enhancement in working site efficiency.

Advantage (2): Safe Construction

PPVC helps ease site labour’s working intensity, while offering more assurance for construction workplace safety.

Advantage (3): Automated Production, Good Casting Quality and More Cost Saving

The extendable steel structure and automated control systemcan replace manual operations by machineries, realizingautomated clamping and demoulding of the product outcomes. Compared with the traditional steel formwork, it saves upover 40% of labour cost.

The self-equipped with internal and the external support frame system does not need the tie-rod system to withstand sidepressure of concrete pouring. With this technique in place. the production svstem can effectively minimize its dependenceon labours, maximize the guality of precast outcome. and the most importantly, decrease the possibility of water leakagein the building formed by the system, Outcome of product casting is similar to effect of fair-faced concrete.

Advantage(4): Environmental Friendly

The green, low-carbon and highly automated operating environment, in line with the trend of global low-carboneconomy and the green building concept advocated by governments of various countries, is gradually replacingthe operating environment brought by conventional construction technologies.