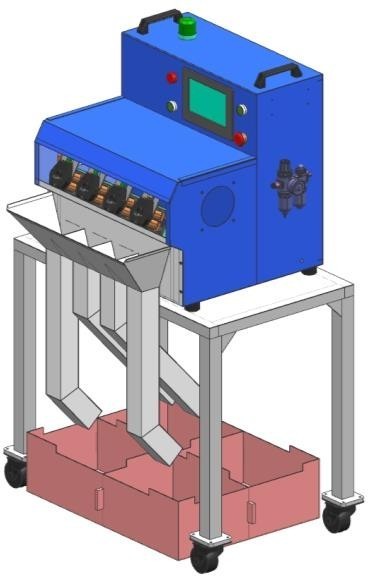

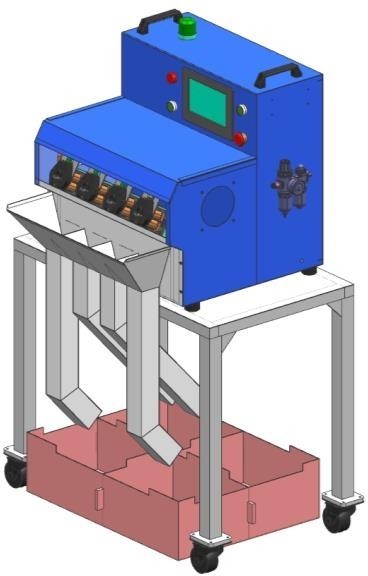

The desktop automatic debeaker is specially developed and designed by our

company for the incubation industry. Based on our company's incubation production

practice and the experience of R&D personnel engaged in the development and

production of automated equipment, a new humanized automatic model - desktop

type is launched. Debeaker.

The device adopts a touch control screen and a dedicated multi-function window to

guide the operation, which is convenient for users to use. This machine has a

complete automatic beak cutting process; it adopts high-efficiency brand electrical

components, which is stable and efficient, easy to learn, understand and maintain; the

temperature control system uses PID temperature control intelligent module, with

automatic temperature compensation function, effectively ensuring the stability of

beak cutting temperature Reliable, and the temperature can be adjusted at will from

the touch screen. At the same time, this machine has a variety of functions such as automatic

counting, temperature control display, parameter display, temperature touch setting

adjustment, induction detection and fault prompt; it realizes personalized automatic

beak cutting, and also has a manual debugging function for the adjusting technician. A

single module is adjusted and maintained for easy maintenance and repair.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Silver Star

-

Model Number:

-

YHD-2500

-

Name:

-

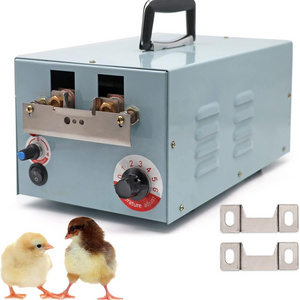

automatic debeaking machine for poultry chicks

-

Usage:

-

poultry chicks beak cutting

-

Size:

-

91*70*120cm

-

Capacity:

-

4000 chicken per hour

-

Electricity Power:

-

220v, 50hz, 2kw

-

Relative Humidity:

-

less than 80%

-

Ambient Temperature:

-

-10℃~40℃

-

Demand Air Pressure:

-

0.3~0.5Mpa

-

Application:

-

Poultry Chicken Equipments

Quick Details

-

Weight (KG):

-

100

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Silver Star

-

Model Number:

-

YHD-2500

-

Name:

-

automatic debeaking machine for poultry chicks

-

Usage:

-

poultry chicks beak cutting

-

Size:

-

91*70*120cm

-

Capacity:

-

4000 chicken per hour

-

Electricity Power:

-

220v, 50hz, 2kw

-

Relative Humidity:

-

less than 80%

-

Ambient Temperature:

-

-10℃~40℃

-

Demand Air Pressure:

-

0.3~0.5Mpa

-

Application:

-

Poultry Chicken Equipments

Product Description

Full Automatic Poultry Chicks Debeaking Machine No Blood Debeaker

Specification

|

Capacity (hourly)

|

2500-4000pcs/hour

|

|

Display range of beak cutting temperature

|

adjustable from 0 to 999°C (the factory

setting temperature is 350°C) |

|

Temperature measurement accuracy

|

±1℃

|

|

The number of beak cuttings

|

the maximum can be recorded 9,999,999 times

|

|

Beak cutting cycle (single)

|

1. 0-2S/piece (factory setting is 2S)

|

|

Working table height

|

700mm

|

|

Equipment dimensions

|

length 0.8 meters * width 0.7 meters * height 1.3 meters

|

|

The total power of this equipment

|

2KW

|

|

Warranty of core components

|

3 years

|

|

Working voltage

|

220V, 50HZ

|

|

Relative humidity

|

less than 80%

|

|

Ambient temperature

|

-10℃~40℃

|

|

Brand Name

|

Silver Star

|

|

Model Number

|

YHD-2500

|

|

Applicable Industries

|

Farms, Retail

|

|

Other Names

|

desktop automatic debeaker, poultry debeaking machine

|

|

Usage

|

poultry chicks beak cutting

|

|

Demand air pressure

|

0.3~0.5Mpa

|

|

Main component structure

|

single head beak breaker and hanging chicken components

|

|

Packaging

|

Wooden box packages

|

|

Delivery time

|

In 20days

|

|

|

|

|

|

|

|

|

|

Advantages Of Automatic Debeaking Machine

1. It is convenient to debug and replace the broken beak chicken breed, and can realize the numerical control adjustment of distance;

2. The relative production speed of the equipment is determined by the operator, the more familiar the operation, the higher the production capacity;

3. the beak-breaking mouth can be cleaned in time according to the amount of beak-breaking;

4. the chicken can be operated at any station;

2. The relative production speed of the equipment is determined by the operator, the more familiar the operation, the higher the production capacity;

3. the beak-breaking mouth can be cleaned in time according to the amount of beak-breaking;

4. the chicken can be operated at any station;

5. the size of the beak can be fine-tuned according to customer needs (standard is 1/2 for the upper beak, 1/3 for the lower beak).

Packing & Delivery

Wooden box packaging

Related Products

Contact Information

Hot Searches