- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

200 KG

-

Product name:

-

laser welding machine

-

Laser power:

-

1000/1500/2000W

-

Use:

-

metal welding

Quick Details

-

Max. Output Power:

-

1000W/ 1500W/ 2000W

-

Usage:

-

Jewelry/ Gold/ silver/ copper/ alloy/ aluminum

-

Laser Source Brand:

-

Raycus

-

Place of Origin:

-

China

-

Weight (KG):

-

200 KG

-

Product name:

-

laser welding machine

-

Laser power:

-

1000/1500/2000W

-

Use:

-

metal welding

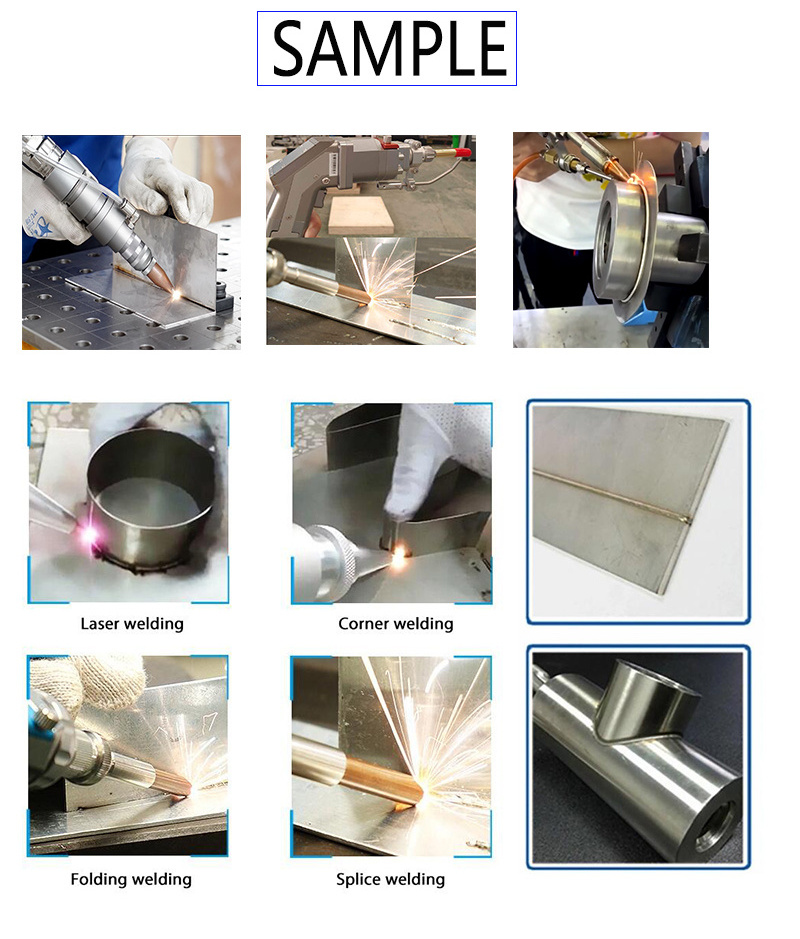

Laser Welding Machine

Model features:

High energy density, low heat input, small amount of thermal deformation, and narrow melting depth in the heat and heat affected zone of the melting zone.

The cooling rate is high, so that the weld structure can be fine and the joint performance is good.

Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly improving work efficiency.

The weld is fine, the penetration is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

No consumables, small size, flexible processing, low operating and maintenance costs

The laser is transmitted through the optical fiber and can work with the assembly line or the robot.

|

Model No. |

1000W/1500W/2000W |

|

Laser Type |

Continuous Fiber Laser |

|

Laser Power |

Raycus 1000W/1500W/2000W(Option: JPT/IPG/ ) |

|

Laser Wavelength |

1070nm+/-5nm |

|

Welding Speed |

0~120mm/s |

|

Optical Fiber Laser Length |

Standard 5m(Option: 10m/15m) |

|

Cooling Method |

Industrial Water Cooling |

|

Welding Thickness |

0~10mm |

|

Optimal operating environment |

Temperature: 15~35ºC Humidity: 20% -80% |

|

Operating Voltage |

AC220V/50Hz |

|

Average Consumed Power |

2000~4000W |

|

Pulse Width |

0.1-50MS |

|

Focal Spot Diameter |

0.2-3.0mm |

|

Dimensions |

1730*1250*870mm |

|

Weight |

3 00kg |

laser welding machine

is widely used in high-precision metal parts welding, electronic components welding, picture tube electron gun welding, missile detector welding, mobile phone vibration motor welding, detonator engine welding, car lights and xenon lamp welding, precision optoelectronic parts welding, etc.

Pre sales services:

1. Provide consulting support and relevant technical support.

2. Sample test support.

3. Visit our factory.

4. Strict quality inspection must be carried out before delivery.

after-sale service:

1. Our technical engineers can go to the customer's site for installation and training.

2. Customers can study and train in our factory directly.

We provide training, including machine installation, drawing operation, operation, machine troubleshooting

3. Our company provides lifelong technical services for our machines.