- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

4100 mm

-

Backgauge Travel (mm):

-

0 - 550 mm

-

Throat Depth (mm):

-

450 mm

-

Brand Name:

-

Durmapress

-

Power (kW):

-

11 kW

-

Weight (KG):

-

9200 KG

-

Place of Origin:

-

Anhui, China

-

Dimension(L*W*H):

-

4630*1950*1850

-

Product name:

-

Hydraulic Cnc Shearing Machine

-

Application:

-

Sheet Metal Cutting

-

Type:

-

CNC

-

Machine type:

-

Guillotine Metal Cutting Machine

-

Control system:

-

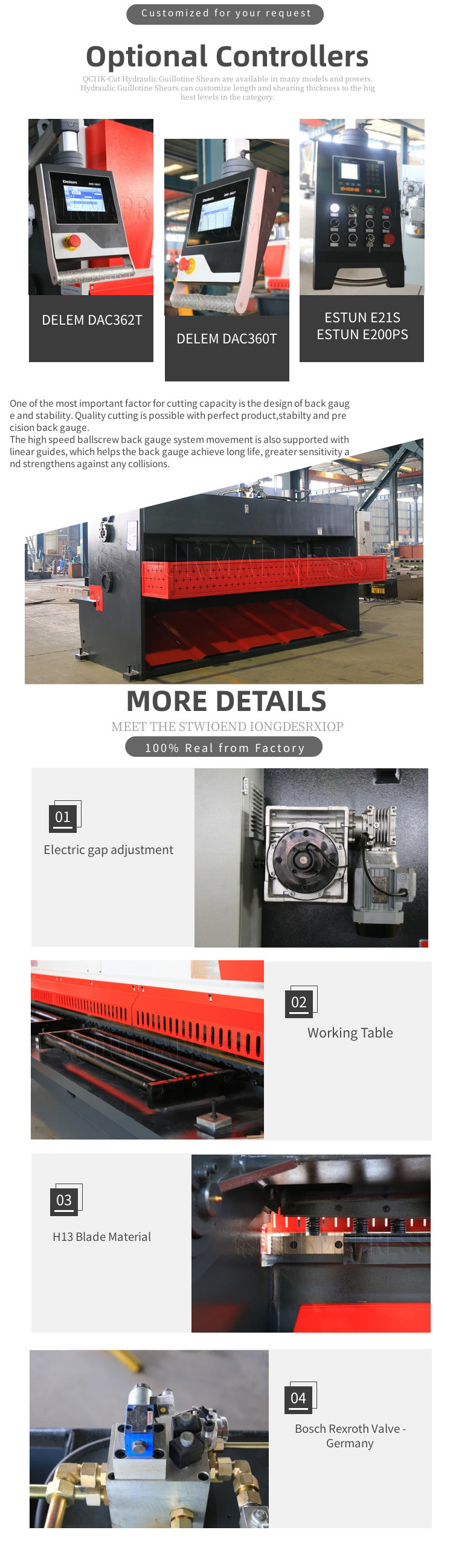

Delem DAC360T

-

Color:

-

Customer Requirement

-

Main Motor:

-

Siemens Germany

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Certification:

-

CE

-

Material:

-

Iron, Stainless, Aluminum

Quick Details

-

Max. Cutting Width (mm):

-

4000

-

Max. Cutting Thickness (mm):

-

20 mm

-

Shearing Angle:

-

1'30

-

Blade Length (mm):

-

4100 mm

-

Backgauge Travel (mm):

-

0 - 550 mm

-

Throat Depth (mm):

-

450 mm

-

Brand Name:

-

Durmapress

-

Power (kW):

-

11 kW

-

Weight (KG):

-

9200 KG

-

Place of Origin:

-

Anhui, China

-

Dimension(L*W*H):

-

4630*1950*1850

-

Product name:

-

Hydraulic Cnc Shearing Machine

-

Application:

-

Sheet Metal Cutting

-

Type:

-

CNC

-

Machine type:

-

Guillotine Metal Cutting Machine

-

Control system:

-

Delem DAC360T

-

Color:

-

Customer Requirement

-

Main Motor:

-

Siemens Germany

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Certification:

-

CE

-

Material:

-

Iron, Stainless, Aluminum

Shearing Machine

The robust monolithic structure is a guarantee of great stability and precision of cut. Even the design is perfected according to criteria of maximum functionality and efficiency, such as to reduce maintenance and operator interventions to the minimum.

Main Configuration

• Solid monolithic structure

• An avant-garde hydraulic system

• Blade carrier beam: Thrust cylinders on the cutting axis with blade carrying beam

• Blade pressure cylinders, with auto-regulating pressure, based on cutting force

• Blade carrying beam guide over the whole cutting length

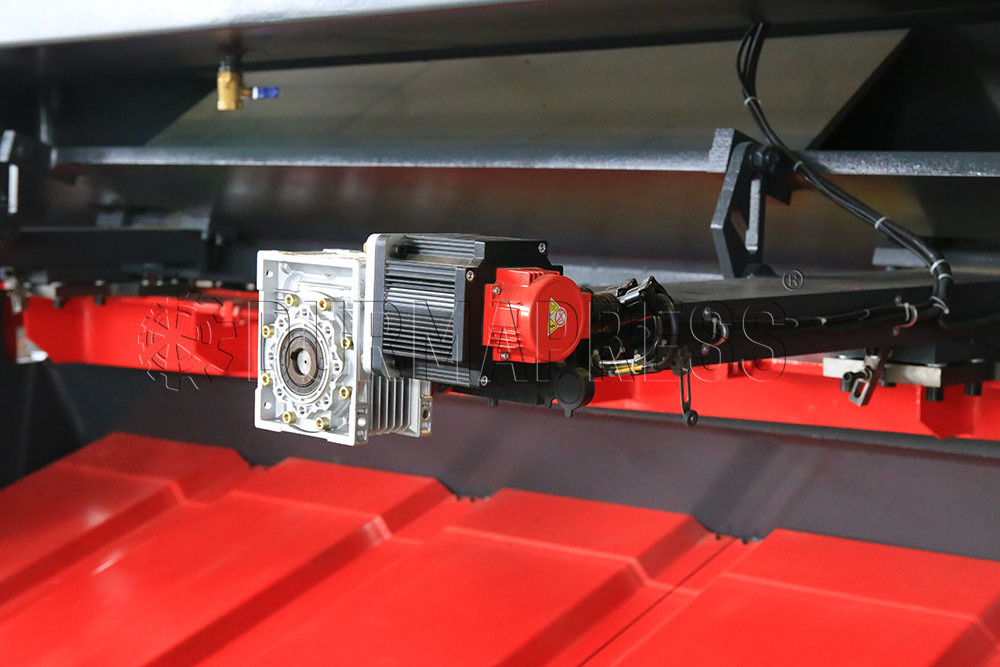

• Rear regulator with recirculating ball screws

• Running wheels' table and frontal support

• Twin-edged blades

• Cutting line with LED illumination

• Frontal support frame complete with retractable adjustable guides, millimetre rule and running wheels

• HIWIN Ball screws & Polished rod with 0,05 mm accuracy.

The robust monolithic structure is a guarantee of great stability and precision of cut. Even the design is perfected according to criteria of maximum functionality and efficiency, such as to reduce maintenance and operator interventions to the minimum.

Main Configuration

• Solid monolithic structure

• An avant-garde hydraulic system

• Blade carrier beam: Thrust cylinders on the cutting axis with blade carrying beam

• Blade pressure cylinders, with auto-regulating pressure, based on cutting force

• Blade carrying beam guide over the whole cutting length

• Rear regulator with recirculating ball screws

• Running wheels' table and frontal support

• Twin-edged blades

• Cutting line with LED illumination

• Frontal support frame complete with retractable adjustable guides, millimetre rule and running wheels

• HIWIN Ball screws & Polished rod with 0,05 mm accuracy.

|

Name

|

Unit

|

12x2500

|

12x3200

|

16x3200

|

16x4000

|

20x3200

|

20x6000

|

|

Max Cutting Thickness

|

mm

|

12

|

12

|

16

|

16

|

20

|

20

|

|

Max Cutting Length

|

mm

|

2500

|

3200

|

3200

|

4000

|

3300

|

6100

|

|

Strength of Sheared plate

|

N/mm²

|

450

|

450

|

450

|

450

|

450

|

450

|

|

Length of Cutter Blade

|

mm

|

2600

|

3300

|

3300

|

4100

|

3300

|

6100

|

|

Cutting Angle

|

°

|

0.5-2.0

|

0.5-2.0

|

0.5-2.0

|

0.5-2.0

|

0.5-2.0

|

0.5-2.0

|

|

Backgauge Range of X Axis

|

mm

|

10-800

|

10-800

|

10-800

|

10-800

|

10-800

|

10-800

|

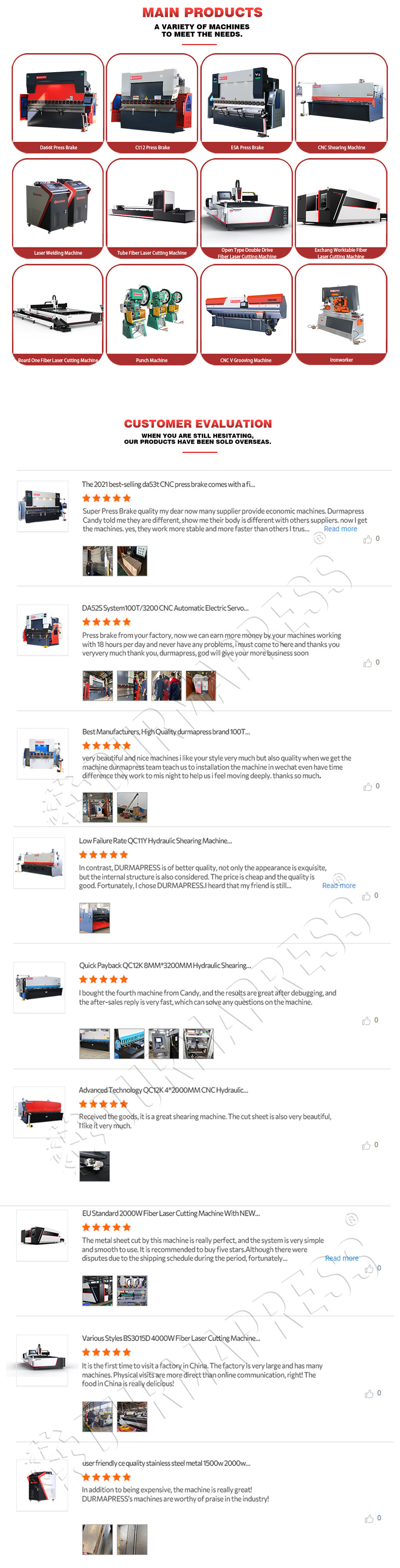

Maanshan Durmapress Machinery Technology Co,. Ltd. DURMAPRESS( Branch Brand: Bossorlaser)is a famous brand company in China, which is dedicated to development, production and sales of sheet metal equipment(Press Brake, Shearing Machine, lrowworker, Punching machineand etc). Located in Maanshan, Anhui Province, After 15 years development, it has been a famous and influential modern enterprise which owns two Subsidiary corporations -Maanshan Durmapress Machinery Technology Co.,Ltd and Nanjing Bosslaser CNC Technology Co.Ltd (Professional for Fiber Laser Cutting Machine Adhering to the advanced European design concept, Boslaser follow the technology of Belgian R&.D center.combine with the actual needs of customers, and make well-structured and high-quality sheet metal fabrication equipment. Most importantly, it makes us be the professional sheet metal processing equipment supplier.

FAQ

Q: How to get a accurate quotation from us ?

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with

postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Our Service

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with

postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Our Service

1. Installation Services

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and

preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician

to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. Machine warranty is 5 years.

Installation Services are available with all Our machines. We dispatch technician to customer's factory for installation and

preoperation of machines. ( Customers only need to pay the airfare and hotel )

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician

to our company to learn how to operate machines.

3.Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data. Machine warranty is 5 years.

Hot Searches