- Product Details

- {{item.text}}

Quick Details

-

Power:

-

168-292KW

-

Weight:

-

8 KG

-

Dimension(L*W*H):

-

55x2.8x2.7m

-

Name:

-

Rice Crispy Cereal Corn Flakes Extruder Machine

-

Capacity:

-

60-80kg/h 100-150kg/h 200-250kg/h 300-350kg/h

-

Shapes:

-

chips ball moon star,animal,ring ,friut loops etc

-

Company:

-

Jinan DG machinery co.,ltd

-

Machines material:

-

Food grade stainless steel 304

-

Whatsapp/Tel:

-

+86-15553816454

-

Products:

-

Corn flakes,Cereal Snacks Food

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DG

-

Voltage:

-

380V 50HZ three phase

-

Power:

-

168-292KW

-

Weight:

-

8 KG

-

Dimension(L*W*H):

-

55x2.8x2.7m

-

Name:

-

Rice Crispy Cereal Corn Flakes Extruder Machine

-

Capacity:

-

60-80kg/h 100-150kg/h 200-250kg/h 300-350kg/h

-

Shapes:

-

chips ball moon star,animal,ring ,friut loops etc

-

Company:

-

Jinan DG machinery co.,ltd

-

Machines material:

-

Food grade stainless steel 304

-

Whatsapp/Tel:

-

+86-15553816454

-

Products:

-

Corn flakes,Cereal Snacks Food

Brief introduction of the corn flakes and nutritional cereal processing line:

There are more other shapes of breakfast cereal snacks you can make with the same production line , you only need to change the dies on the extruder .

1. Raw Materials: Main corn Powder and Other Cereals Powder

2. Products: All kinds of snacks with different shapes and types.

3. Capacity:

60-80 KG/H

,

100-150KG/H

,

200 -250KG/H

,

300-350 KG/H

4. Flow Chart: Mixing —Extruding —Flaking —Drying — Baking —Coating —Baking —Cooling

5. Voltage: Three phases:

380V/50HZ

, Single phase:

2

20V/50HZ

,

also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by

food grade stainless steel

.

Technical Parameters of Breakfast Cereal Production Line :

| Model | Installed power | Power consumption | Throughput | Dimension |

| DG32-II processing line | 135KW | 101KW | 60-80kg/h | 45X2.8X2.7M |

| DG52-II processing line | 210kw | 168KW | 100-150kg/h | 54.7X2.8X2.7M |

| DG75-II processing line | 292KW | 219KW | 200-250kg/h | 64.2X3.2X3.1M |

| DG75-II B processing line | 342KW | 256KW | 300-350kg/h | 69X3.3X3.8M |

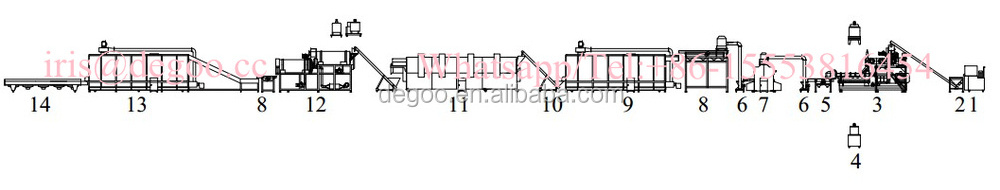

CAD drawing of Corn Flakes and Breakfast cereal production line (Example:300-350kg/h):

Brief introductions of single machines of the corn flakes and cereal processing line:

1 .Flour mixer : to mix various raw materil evenly.

2.Screw conveyor : to convey raw material to extrude

3.Twin/Double screw extruder : to extruder and cook the raw material into different shapes breakfast cereal

4.Water injector: to inject water on the producing process.

5.Vibrating cooler: to spread the products and cool it quickly.

6.Air conveyor: to convey the food to the next machine

7.Flakes presser: to press the particles into thin flakes (its size of flakes can be adjusted)

8.Higher vibrating cooler: to spread the flakes and sancks food and cool it quickly.

9.Belt drying oven: to dry snacks food by circulating belt.

10.Belt conveyor: to elevate the snacks food to the next machine

11.High temperature toaster: to use hot air to dry the snacks food.

12.Flavoring machine: to spray flour ,sugar oil and other seansons on the food to get decilious food.

13.Extending drying oven: to dry the corn flakes after it being coated sugar.

14.Cooling conveyor: to cool food.

Instelled corn flakes production line in clients' factory

Dg75-II is the most popular corn flakes production line , we have improved this line for many time to meet EU standard , with our advanced extruder and assistant machine , you can have a high standard corn flakes making machine / production line to make super quality corn flakes same as Kelloggs or Nestle

1.Something about Jinan DG Machinery Co., Ltd

Established in the year of 2012 , a professional team with more than 20 years experience in the extrusion system industry , Jinan DG Machinery Co., Ltd grows very fast in 3 years, to becoming a leading manufacturer in Chine Extrusion System Industry .

2.What is the advantage of your corn flakes making machines ?

We have different series of twin screw extruder for making breakfast cereals snacks .

The traditional type extruder : DG65-III DG70-II DG85-IV

We also have Advanced type extruder for corn flakes : DG52-II DG75-II DG95-II

4. Which famous brand of parts we use for the corn flakes making machine ?

Machine shield : 201 ss / 304 ss as required

Parts contact with food : 201 ss / 304 ss as required

Main motor: Siemens brand

Touch screen : Wenview brand

Miniature circuit breaker :

ABB

brand

Alternating current contactor:

ABB

brand

Thermal Relay: ABB brand

Moulded case circuit brake : CHNT brand

Small relay: Weidmuller brand

Inverter:

Delta

brand

PLC system: Delta brand

Burner: Baltur brand

Bearing : NSK/ SKF brand