- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to requirement

-

Year:

-

2020

-

Warranty:

-

1 year

-

Power (kW):

-

90 kW

-

Weight (KG):

-

19000 KG

-

Certification:

-

ISO9001,2008,BV,CE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

Scrap tire reclamation equipment for tire retreading

-

color of machine:

-

depend on customer's requirment

-

production capcity:

-

200-1200kg/h

-

type:

-

rubber powder production

-

installation:

-

free

-

Series:

-

tyre recycling machine

-

Service provided:

-

engineer is available to service

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

eenor

-

Voltage:

-

220V-510V

-

Dimension(L*W*H):

-

According to requirement

-

Year:

-

2020

-

Warranty:

-

1 year

-

Power (kW):

-

90 kW

-

Weight (KG):

-

19000 KG

-

Certification:

-

ISO9001,2008,BV,CE

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

Scrap tire reclamation equipment for tire retreading

-

color of machine:

-

depend on customer's requirment

-

production capcity:

-

200-1200kg/h

-

type:

-

rubber powder production

-

installation:

-

free

-

Series:

-

tyre recycling machine

-

Service provided:

-

engineer is available to service

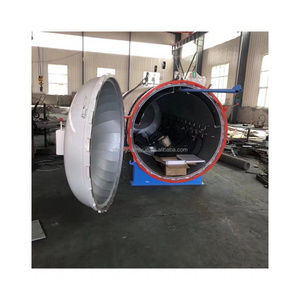

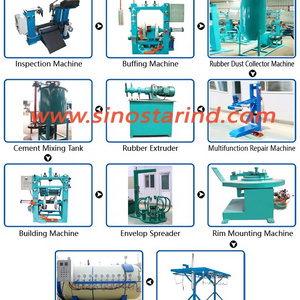

Scrap tire reclamation equipment for tire retreading/tires refurbished machinery

Description:

Our factory has nearly 30 years' experience in manufacturing rubber machine. We have a set of standardized production line,which contains wire peeling machine,rubber cutter, grinding mill,shredder,screen conveyor,rubber crusher,shaker, banburying mixer,open mill,spiral elevator, kneader,rubber filter and extruder,vulcanizer,refiner,calendering machine.

Production process:

Tire ring cutter → steel wire extractor→ tire shredder→ rubber coarse crusher→ magnetic separator→ vibrating screen1→ fine rubber crusher→ vibrating screen2 → cyclone classifier→ storage bin→ rubber grinder →vibrating screen3→

package.

The whole line features:

1), iron/steel removing ratio>99.5%, fiber removing ratio>98%

2),compact structure ensure running safety, easy maintenance;

3),low energy consumption;

4),adopt automatic control system for whole line, reduce labor cost;

5),no sewage and waste gas discharge, environment protection.

6), available capacity range of our tire recycling lines at present: 400~3000kg/h

7), available finial rubber powder size: 30~120mesh.

8), adopts SIEMENS and Chinese famous brand electrical elements.

Note:

there is 3 types of rubber crusher, you can choice the suitable one ,it is depend on the output!

You not need Granulator Grinder if your final rubber powder bigger than 30 mesh. but we need it if the powder less than 30 mesh and the number of this machine depend on the output!

Analysis for output:

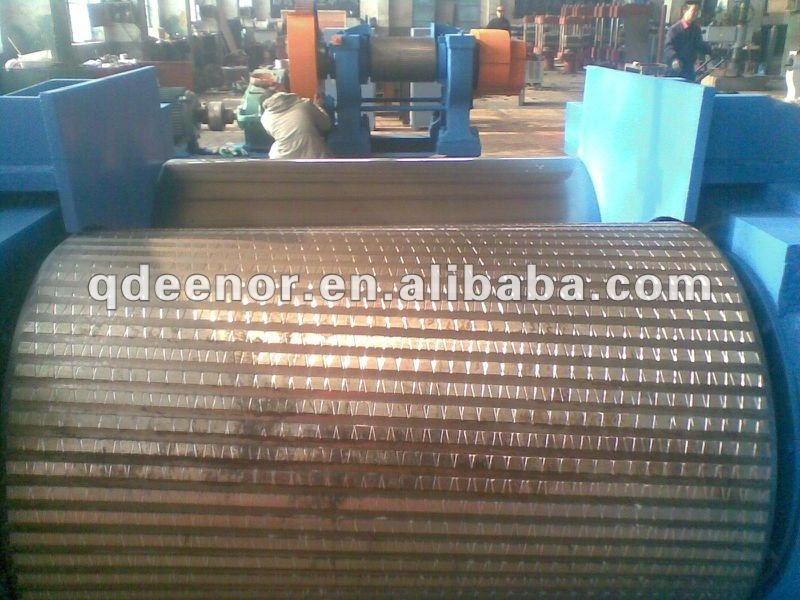

1. The crusher is mainly composed of by base ,frame,front and back roller,reducer, motor,gap regulating device,safety

switch,electrical control system;

2. Roller is made of compound alloys and its working surface hardness is HS68 degree, hardness layer is 5-15 mm. Working surface has been grinding processed ,high har dness,abrasion resistance.

3. Interlock power protection to ensure operational safety. The machine is equipped with automatic brakes,when emergency happens,push the button,and it can immediately brake.

4. High-speed quality cutter, sharp edge, durable in operation;

5. Heavy-duty bearings, rolling bearings,large inertial wheel and strong crushing ability.

6. Tight construction, small space and simple technique flow.

7. Low energy-consuming and good performance-cost ratio.

8. All electrical connections are safe:short circuit is not possible by any means.

|

Type&Specification |

XKP-400 |

XKP-450 |

XKP-560 |

|

Feeding size |

3.5CM |

3.5CM |

3.5CM |

|

Discharging size |

10—30 mesh powder |

10--30 mesh powder |

10--30 mesh powder |

|

Rubber crusher throughput(kg/h) |

260-300kg/h |

350-400kg/h |

400-500kg/h |

|

Motor power(kw) |

45 |

60 |

75 |

|

Outside measurement(m) |

4.1×1.8×1.9 |

4.4×1.9×1.9 |

5.5×2.2×2.1 |

|

Weight(t) |

7.5 |

11 |

19 |

2.conveyor belt, oscillating screen, magnetic roller: To separator the iron power and rubber power and screening the rubber power, make the big rubber power re-milling.

3.fiber separator: separator the fiber from rubber power.

4.This is grinder machine, which directly determines the customer needs the final mesh rubber powder.

5 . Shipping

Company and customers:

A satisfies customer can bring you ten more customers but one disappointed customer can send away one

hundred customers. Reputation in the market is the most important factor for keeping business healthy and

in growing line.

Our philosophy: The honesty is the root,A promise is a promise.

Welcome to our factory to visit our producs!