- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to machine model

-

Weight:

-

2500 KG

-

Product name:

-

Super quality mine grinding vibrating ball mill

-

Feature:

-

Low cost,low noise,fine discharge

-

Manufacturer:

-

Xinxiang City Leader Machinery Co., Ltd.

-

Voltage:

-

380V,400V,415V,440V/as your requirement

-

Painting Color:

-

Optional(blue,yellow,light grey,etc)

-

Working condation:

-

continuously working

-

Grinding way:

-

Wet type and dry type

-

Operation training:

-

Provided

-

Price:

-

Negociable

-

Installation:

-

Under Technical Guidance

Quick Details

-

Capacity(t/h):

-

0.1-1.5T

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leader

-

Dimension(L*W*H):

-

According to machine model

-

Weight:

-

2500 KG

-

Product name:

-

Super quality mine grinding vibrating ball mill

-

Feature:

-

Low cost,low noise,fine discharge

-

Manufacturer:

-

Xinxiang City Leader Machinery Co., Ltd.

-

Voltage:

-

380V,400V,415V,440V/as your requirement

-

Painting Color:

-

Optional(blue,yellow,light grey,etc)

-

Working condation:

-

continuously working

-

Grinding way:

-

Wet type and dry type

-

Operation training:

-

Provided

-

Price:

-

Negociable

-

Installation:

-

Under Technical Guidance

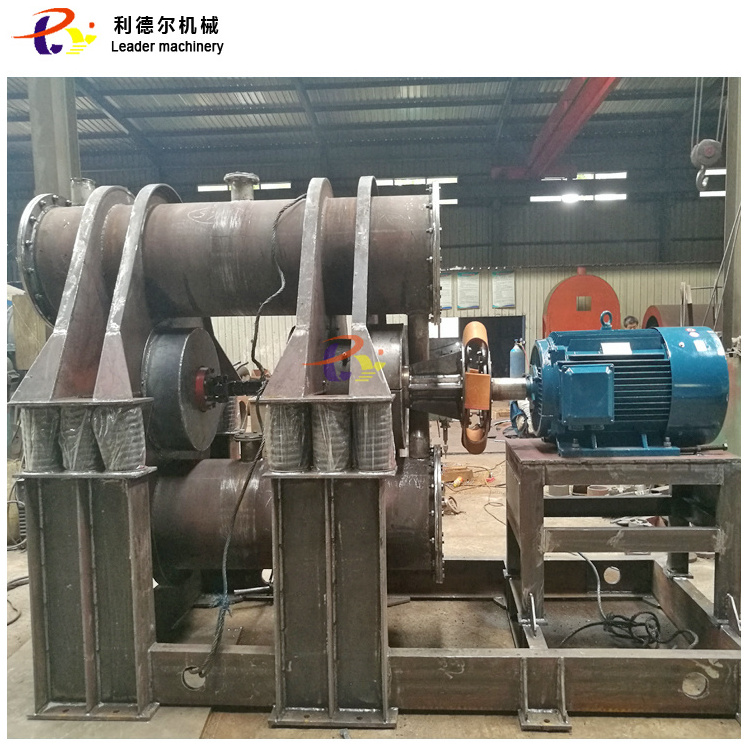

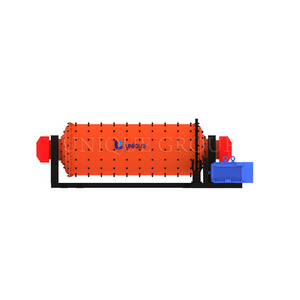

Super quality mine grinding vibrating ball mill

Introduction

2ZM series of vibrating mill is a new type of efficient grinding equipment in grinding fine and super fine powder materials. It is more convenient than conventional rotary grinding machine (efficiency of 2-5 times, reducing energy consumption by 20% - 30%). The machine has various vibration strength, high efficiency, low power consumption, less noise and compact structure, convenient installation and maintenance,etc. The vibrating mill falls in with popular demands.

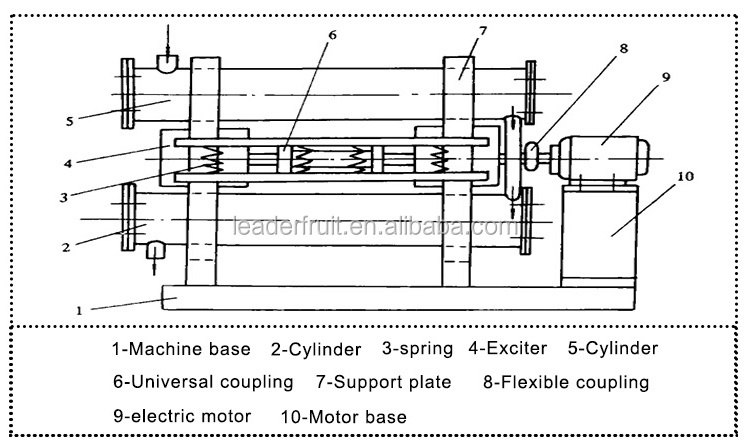

The high efficiency vibration mill is mainly composed of the base frame, the body frame, the acoustic enclosure, the body, the grinding cylinder, the vibrator, the lining plate, the spring support, the grinding medium and the driving motor.

Turn on the power, drive the motor through the flexible coupling to drive the vibrator to rotate, generating enough excitation force, keep the grinding cylinder in a cyclic vibration state. The vibration force is continuously transmitted to the entire material in the grinding drum, the milled material is finely ground by mutual impact between the drum medium and the material.

The machine can be widely used in mineral, building materials, grinding materials of powder metallurgy, electric, ceramic, refractory, magnetic material, Chemical, food, and other industries, it is the ideal substitute of ball mill.

|

Model |

2ZM-100 |

2ZM-200 |

2ZM-400 |

2ZM-600 |

2ZM-800 |

2ZM-1200 |

2ZM-2000 |

|

Tube No. |

2 | 2 | 2 | 2 | 2 | 2 | 2 |

|

Total volume(L) |

100 | 100 | 100 | 100 | 100 | 100 | 100 |

|

Grinding situation |

Wet or dry | ||||||

|

Feeding size(mm) |

0-25 | ||||||

|

Discharge size(mm) |

0.3-0.074 | ||||||

|

Capacity(t/h) |

0.1-1.5 | 0.2-3 | 0.5-5 | 1-10 | 1-10 | 1-16 | 1-40 |

|

Vibrating amplitude(mm) |

9-14 | 9-14 | 8-11 | 7-9 | 7-9 | 7-9 | 7-9 |

|

Power (kw) |

17-22 | 22-37 | 45-55 | 45-55 | 55-75 | 75-90 | 135 |

|

Weight (t) |

2.5 |

4 | 5.2 | 6.6 | 11.5 | 14 | 20 |