- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Wanrooe

-

Weight (T):

-

1

-

Product name:

-

20-80 Mesh Waste Tire Pulverizer Rubber Powder Grinding Machine

-

Shredder Blades Material:

-

Specially Alloy Ateel

-

Weight:

-

2500kg

-

Power(W):

-

78/75kw

-

Working theory:

-

fixed and mobile disk

-

Feed size:

-

1-8mm

-

Final fineness:

-

20-80mesh

-

Certification:

-

CE ISO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Max.Production Capacity (kg/h):

-

2500

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

100 - 2500 kg/h

-

Brand Name:

-

Wanrooe

-

Weight (T):

-

1

-

Product name:

-

20-80 Mesh Waste Tire Pulverizer Rubber Powder Grinding Machine

-

Shredder Blades Material:

-

Specially Alloy Ateel

-

Weight:

-

2500kg

-

Power(W):

-

78/75kw

-

Working theory:

-

fixed and mobile disk

-

Feed size:

-

1-8mm

-

Final fineness:

-

20-80mesh

-

Certification:

-

CE ISO

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

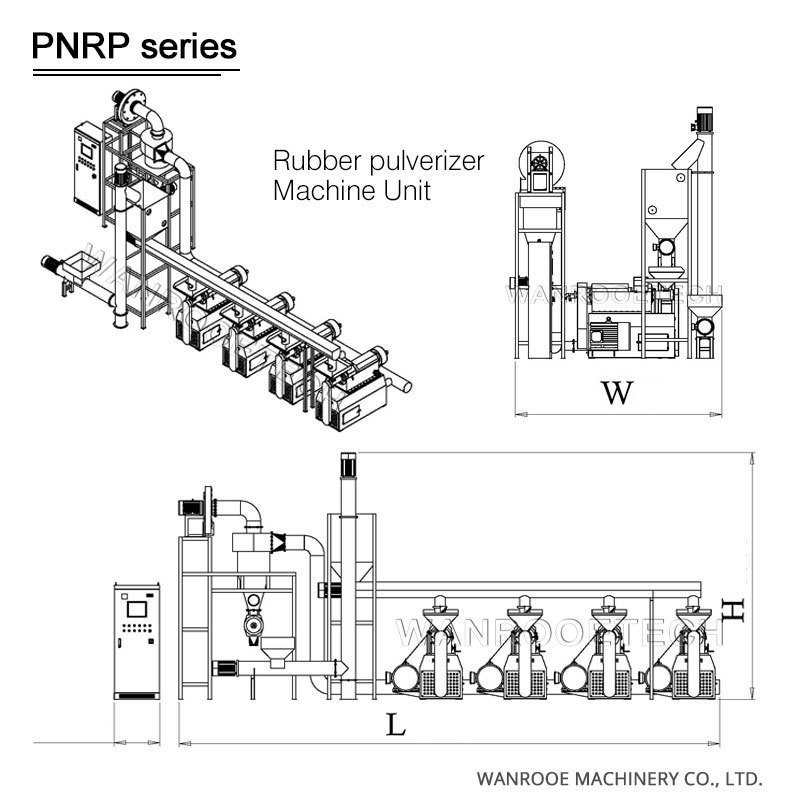

High Quality 20-80 Mesh Waste Tire Pulverizer Rubber Powder Grinding Machine

Applications:

Rubber powder is widely used in sports plastic playgrounds, playgrounds, rubber tile, waterproof membrane, waterproof coating, road modified asphalt, rubber products, and other fields.

Biref Instruction:

Our factory is a high tech enterprise which specializer in the research, development production and making of environmental mechanical equipments. After many years developing, we are becoming a leading manufacturer in China in producessing plastic waste and scraps tire. And the tire recycling plant can be up to the capacity from 1000Tons to 6000Tons per year. Unitl now, we have opened many markets, such as, Mexico, Russia, Poland, India etc. We hope we can achieve much more success in the near future.

Features:

1. Shrede and pulverize the waste tire into the rubber power of 40-120mesh, and automatically separate the steel wire, fiber, Nylon compeltely through magnet separator and vibrating screen at normal temperature.

2. Compact structure, small space and easy maintennance

3.Lower energy consumption and good cost performance of investment

4.High-automatic and programmed control, higher coperatioin stability and more efficient running

5.No polluted water, no waste gas and no waste residuce during production process.

Technical Parameter:

| Model | RP-280 | RP-300 |

| Main motor power | 22kw*3=66kw | 30kw*3=90kw |

| Speed motor power | 1.5kw*3=4.5kw | 1.5kw*3=4.5kw |

| Air blower power | 7.5kw | 7.5kw |

| Air seal power | 0.75kw | 0.75kw |

| Feed size | 1-8mm | 1-8mm |

| Final fineness | 20-80mesh | 30-100mesh |

| Capacity | 200-500kg/h | 300-500kg/h |

| Working temperature | <70℃ | <70℃ |

| Dimension | 1560*1500*1400mm | 1560*1500*1400mm |

| Weight | 2000kg | 2500kg |