- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jinhui

-

Model Number:

-

680

-

Type:

-

Liquid Glue

-

Calor:

-

green

-

Viscosty:

-

1250 mPa.s

-

Fill gap:

-

0.13 mm

-

Temperature:

-

-54~149 °C

-

Fixture time/full cure time:

-

10 min / 24 h

Quick Details

-

CAS No.:

-

mixcure

-

Other Names:

-

anaerobic adhesive

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinhui

-

Model Number:

-

680

-

Type:

-

Liquid Glue

-

Calor:

-

green

-

Viscosty:

-

1250 mPa.s

-

Fill gap:

-

0.13 mm

-

Temperature:

-

-54~149 °C

-

Fixture time/full cure time:

-

10 min / 24 h

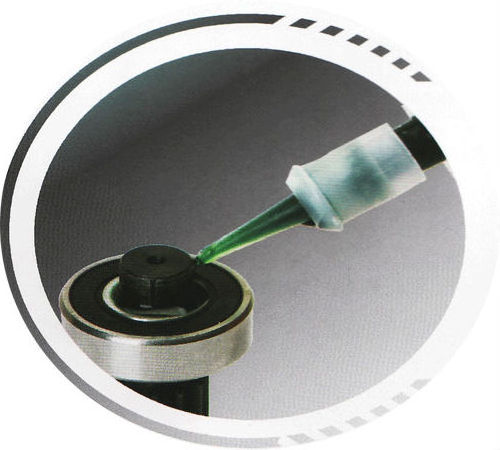

Retaining Compound 680 For retaining cylindrical axle and bushing wheel bearing

JH680 Retaining Compound

1, Slip fit,high strength;

2, For retaining cylindrical axle and bushing, wheel bearing; or for refitting worn shafts, housing and keyway etc;

3, Gaps fill up to 0.25mm.;

4, Fixture in 10 minutes.

Product description

|

Chemical Type |

Methacrylate |

|

Appearance (uncured) |

Green liquid |

|

Components |

One component |

|

Strength |

High |

|

Viscosity |

Medium |

|

Cure |

Anaerobic |

|

Application |

Retaining |

Typical application

JH680 is designed for the bonding of cylindrical fitting parts. The largest bond gaps can approach 0.25mm. It cures when confined in the absence of air between close fitting metal surfaces and prevents loosening and leakage from shock and vibration. It is used for retaining cylindrical axle and bushing, wheel bearing or for refitting worn shafts, housing and keyway etc.

Typical properties of uncured material

|

Gravity @25°C |

1.09 |

|

Viscosity, 25°C, mPa•s (cP): |

800 to 1500 |

|

Flash point |

>93°C |

|

Cure speed |

Fixture cure time 10min , full cure time is 24 hours |

Typical properties of cured material (Low carbonate grit blasted steel, @22 °C, after 24hr full cured)

|

Temperature (°C) |

-50 —150 |

|

Shear strength ISO-10964(N/mm2) |

15 — 25 |

|

Breakaway Torque ISO-10964 (N.m) |

25 — 40 |

|

Breakloose Torque ISO-10964(N.m) |

30 — 45 |

|

Coefficient of Thermal Expansion, ASTM D 696, K -1 |

80*10 -6 |

|

Coefficient of Thermal Conductivity, ASTM C 177, W/(m•K) |

0.10 |