- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Proman

-

Year:

-

2020

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1.5*0.65*2.0M

-

Hollow part volume:

-

2L

-

Power (kW):

-

11

-

Weight (KG):

-

550 KG

-

Function:

-

Auto Blow Molding Machine

-

Key words:

-

Bottle Blowing Machine 2 Cavity

-

Suitable bottle:

-

PET Bottle size 2L

-

Material of main parts:

-

SUS304/316

-

Productivity:

-

900 PCS/H

-

Cavity:

-

2 Cavity

-

Power:

-

380V or Customer Made

-

Control system:

-

PLC with Touch Screen

-

Electrics:

-

Siemens,Mitsubishi,etc

-

Market:

-

Global Blow Molding Machine

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Marketing Type:

-

New Product 2020

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

360 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Proman

-

Year:

-

2020

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1.5*0.65*2.0M

-

Hollow part volume:

-

2L

-

Power (kW):

-

11

-

Weight (KG):

-

550 KG

-

Function:

-

Auto Blow Molding Machine

-

Key words:

-

Bottle Blowing Machine 2 Cavity

-

Suitable bottle:

-

PET Bottle size 2L

-

Material of main parts:

-

SUS304/316

-

Productivity:

-

900 PCS/H

-

Cavity:

-

2 Cavity

-

Power:

-

380V or Customer Made

-

Control system:

-

PLC with Touch Screen

-

Electrics:

-

Siemens,Mitsubishi,etc

-

Market:

-

Global Blow Molding Machine

-

Blow Moulding Type:

-

Stretch Blow Moulding

-

Marketing Type:

-

New Product 2020

Pet Blowing Machine Bottle Semi-automatic Pet Mineral Water Edible Oil Bottle Making Bottle Blowing Machine 2 Cavity

Semi-automatic bottle blowing machine adopts direct pressure, icrocomputer control, two step blowing bottle. The main blow tube blank PET mineral water bottles, beverage bottles, edible oil bottles, pharmaceutical plastic bottles, pesticide bottles, cosmetic bottles, etc..

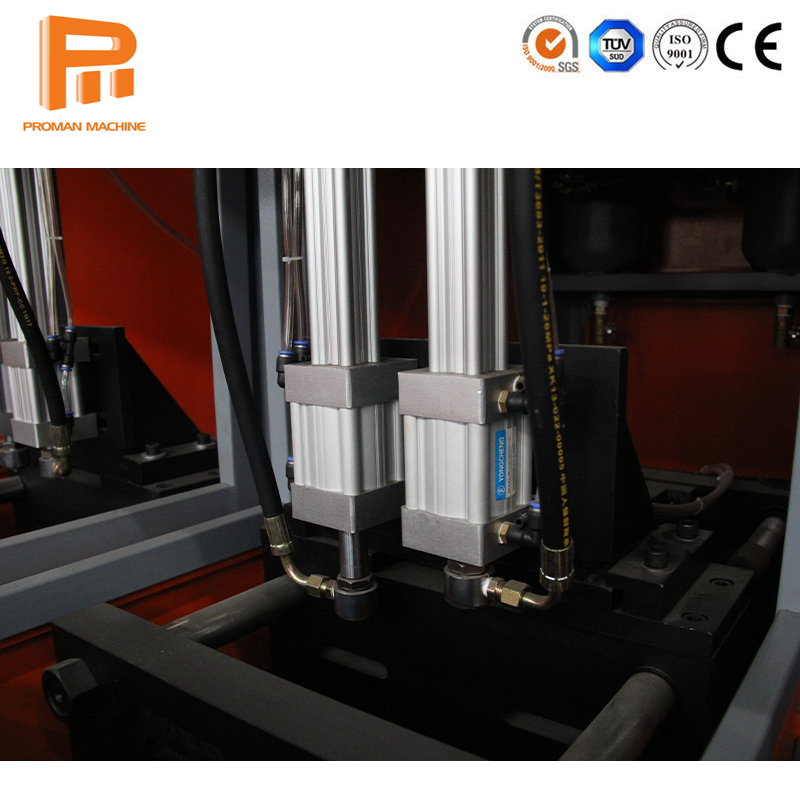

The gas path is designed to separate the gas and blowing, adopting low pressure(0.4-0.8Mpa) mould clamping, mould locking, sealing, stretching and high pressure(3-3.5Mpa) blowing form, and the gas-liquid locking structure, to not only ensure the clamping and locking action smoothly, also ensure the safety of mould and blowing quality, as a result can save the bottle perform material.

Advantages of Our Bottle Blow Molding Machine

1. Produce bottle from 0.1L to 2L(2 cavity)

2. Output capacity up to 900 for 0.6L using two-cavity blow mold

3. Advanced PLC control system with a use-friendly panel and time-control precision of PLC up to 0.01second

4. Equipped with special designed air storage unit

5. Using Infrared preform heater

6. Independent Temperature Control for different heating lamp to get ideal preform heating results

7. Heating lamps are adjustable in directions to suit various preforms

8. Operated only by one person without special training

9. Simple installation & startup adjustment

10. Waste rate of finished bottle is less than 0.2%

Details of Our Bottle Blow Molding Machine

| Model | Item | Unit | PM-12 | PM-8Y | PM-1500 | PM-1-20 |

| Theoretical output | Pcs/H | 500 | 900 | 1800 | 90 | |

| Product | Volume | L | 5.0 | 2.0 | 2.0 | 20 |

| MAX.Height | mm | 360 | 360 | 360 | 550 | |

| MAX.Diameter | mm | 120 | 105 | 105 | 300 | |

| Mould | Number of cavities | / | 1 | 2 | 4 | 1 |

| Mould piate dimension(L*H) | mm | 490*470 | 490*405 | 490*405 | 620*620 | |

| Mould thinkness | mm | 250 | 220 | 220 | 380 | |

| Mould opening stroke | mm | 220 | 180 | 180 | 380 | |

| Electrical | Power | / | 220_380V/50_60HZ | |||

| Total power | KW | 11 | 11 | 21 | 36 | |

| Heating power | KW | 10 | 10 | 20 | 37 | |

| Machine | Main body dimension (L*W*H) | M | 1.5*0.65*2.0 | 1.5*0.65*2.0 | 1.5*0.65*2.0 | 2.1*0.75*1.6 |

| Main body weight | KG | 600 | 550 | 550 | 900 | |

| Pre-heater(L*W*H) | M | 1.5*0.65*1.5 | 1.4*0.65*1.5 | 1.8*0.65*1.5 | 2.7*0.7*1.6 | |

| Pre-heater weight | KG | 300 | 300 | 350 | 400 | |

PET preform→Autoloader→reheater →molding→ bottles