- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

50HZ

-

Welding Area:

-

50-315mm

-

Dimensions:

-

50-315mm

-

Use:

-

Electro fusion fittings of PE

-

Weight (KG):

-

27.2 KG

-

Power (kW):

-

3

-

Name:

-

315 hdpe pe Electrofusion welding machine

-

Application:

-

pe hdpe pipe fittings

-

Model:

-

BDDR315V

-

Certificate:

-

CE ISO

-

Available welding range:

-

50-315

-

MaximumOutput Power:

-

3.0kw

-

AmbientTemperature:

-

-15~+50°

-

Time Accuracy:

-

0.1%

-

Output VoltageAccuracy:

-

1%

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CNBADA

-

Voltage:

-

220V

-

Frequency:

-

50HZ

-

Welding Area:

-

50-315mm

-

Dimensions:

-

50-315mm

-

Use:

-

Electro fusion fittings of PE

-

Weight (KG):

-

27.2 KG

-

Power (kW):

-

3

-

Name:

-

315 hdpe pe Electrofusion welding machine

-

Application:

-

pe hdpe pipe fittings

-

Model:

-

BDDR315V

-

Certificate:

-

CE ISO

-

Available welding range:

-

50-315

-

MaximumOutput Power:

-

3.0kw

-

AmbientTemperature:

-

-15~+50°

-

Time Accuracy:

-

0.1%

-

Output VoltageAccuracy:

-

1%

BDDR315

BADA hdpe pipe full-automatic l butt fusion welding machine manufacture from China connector for electrofusion

|

Mode

|

BDDR-315A

|

BDDR-315V

|

BDDR-315W

|

BDDR-400

|

BDDR-500

|

BDDR-800

|

||||||

|

Welding Range(mm)

|

50-315

|

50-315

|

50-315

|

All 39.5V

standard fittings

|

50-500

|

50-800

|

||||||

|

Operating Voltage

|

175-240V 50HZ AC

|

175-240V 50HZ AC

|

175-240V 50HZ AC

|

175-240V 50HZ AC

|

175-240V 50HZ AC

|

175-240V 50HZ AC

|

||||||

|

Constant Voltage Output Voltage

|

Valid Values10V~50V

|

Valid Values10V~50V

|

Valid Values10V~50V

|

Valid Values10V~50V

|

Valid Values10V~50V

|

Valid Values10V~50V

|

||||||

|

Constant Current /Output Current

|

Valid Values5A~60A

|

Valid Values5A~60A

|

Valid Values5A~60A

|

Valid Values5A~60A

|

Valid Values5A~60A

|

Valid Values5A~60A

|

||||||

|

MaximumOutput Power

|

3.0KW

|

3.0KW

|

3.0KW

|

4.0KW

|

5.0KW

|

10KW

|

||||||

|

AmbientTemperature

|

-15~+50°

|

-15~+50°

|

-15~+50°

|

-15~+50°

|

-15~+50°

|

-15~+50°

|

||||||

|

Time Accuracy

|

0.1%

|

0.1%

|

0.1%

|

0.1%

|

0.1%

|

0.1%

|

||||||

|

Output VoltageAccuracy

|

1%

|

1%

|

1%

|

1%

|

1%

|

1%

|

||||||

|

Storage Records

|

——

|

6×500records

|

6×500records

|

6×500records

|

6×500records

|

6×500records

|

||||||

|

N.G

|

21.7KG

|

21.7KG

|

21.7KG

|

25KG

|

30KG

|

25KG

|

||||||

|

Subject to changes in parameters,subject to the final notice

|

|

|

|

|

|

|

||||||

BDDR315 Light Weight BDDR315 electro fusion welding machine for ppr pe pipe fittings hdpe pe fusion electro machine

Our advantage:

1. High - level MCU is used as control core, with abundant parameter setting, measuring and perfect protective function.

2. Wide power supply and voltage input, suitable for filed electrical network level.

3. High precision control of electrial stability and time, insuring welding quality.

4. Swift output response time when power supply breaks, high satbility.

5. Many programmable welding functions, suitable for welding requirment for various fittings.

6. Flexible welding parameter input mode; manual input through keyboard or bar cod scanning input.

7. Smart Gas, Colud welding is available.

Our advantage:

1. High - level MCU is used as control core, with abundant parameter setting, measuring and perfect protective function.

2. Wide power supply and voltage input, suitable for filed electrical network level.

3. High precision control of electrial stability and time, insuring welding quality.

4. Swift output response time when power supply breaks, high satbility.

5. Many programmable welding functions, suitable for welding requirment for various fittings.

6. Flexible welding parameter input mode; manual input through keyboard or bar cod scanning input.

7. Smart Gas, Colud welding is available.

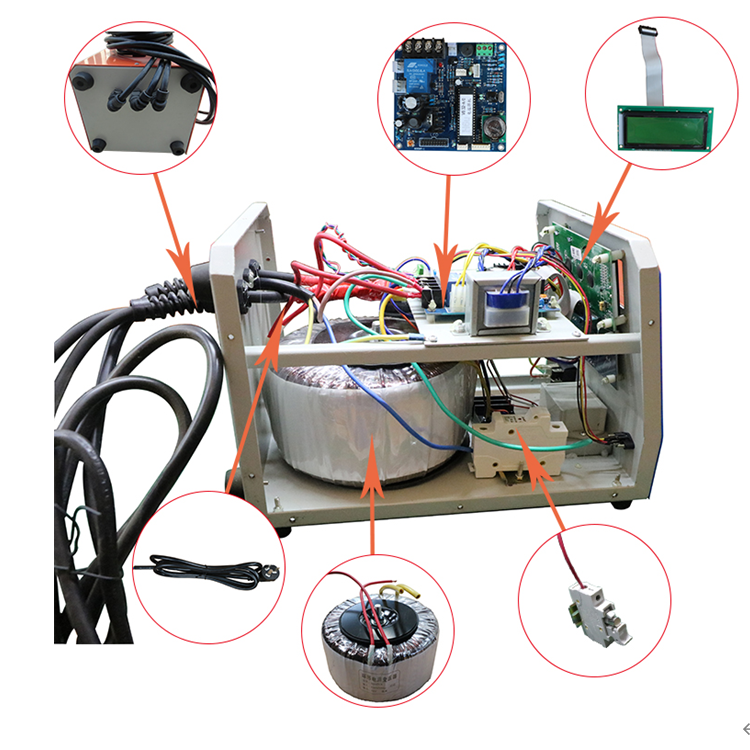

Products Upgrade

We upgrade our technology now

1. Add support legs to prevent moisture, dust and shock absorption.

2. High precision PCB Controller, pure copper transformer, 10mm2 cable, Fuse & Fuse-holder, safer operation.

3. Scraper, spare copper connector, scanner and other optional accessories are complete.

1. Add support legs to prevent moisture, dust and shock absorption.

2. High precision PCB Controller, pure copper transformer, 10mm2 cable, Fuse & Fuse-holder, safer operation.

3. Scraper, spare copper connector, scanner and other optional accessories are complete.

Why choose us

1) Advanced laboratory

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, inspection during the production process, complete machine inspection and

commissioning before delivery.

4) Cooperate with well-known universities, participate in the drafting of GB national standard, provide training for fusion

welding technicians at home and abroad, and support free online video guidance.

5) Sufficient spare parts inventory, short delivery time, less than 50 sets, delivery time 7-10 working days, in line with ROHS

2.0 standard.

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, inspection during the production process, complete machine inspection and

commissioning before delivery.

4) Cooperate with well-known universities, participate in the drafting of GB national standard, provide training for fusion

welding technicians at home and abroad, and support free online video guidance.

5) Sufficient spare parts inventory, short delivery time, less than 50 sets, delivery time 7-10 working days, in line with ROHS

2.0 standard.

Hot Searches