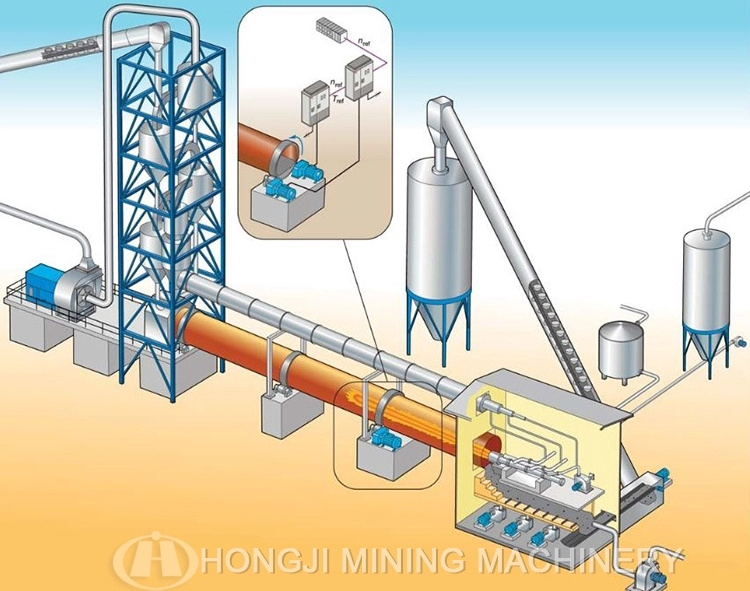

Rotary Kiln belongs to building material equipment, according to different materials, which can be divided into cement kiln, metallurgy chemical kiln and lime kiln. Cement kiln is used for making cement clinker and there are dry and wet methods to make cement clinker. Metallurgy chemical kiln is widely used for magnetic roasting of poor iron ore and oxidizing roasting of chrome and nickel in the steel factory; backing high-alumina mine in the refractory material factory; baking chamotte and alumina in the aluminum factory and baking chrome ore and chrome powder in the chemical plant. The Lime Kiln is used for roasting active lime in

steel works and ferroalloy plants and light roasting dolomite.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-630kw

-

Dimension(L*W*H):

-

Production Capacity

-

Weight:

-

10 kg

-

Product name:

-

Small Scale Rotary Kiln Making Quick Active Lime Processing Plant

-

Fuel:

-

coal,mazut,gas etc

-

spare parts supply:

-

for the whole using life

-

Install:

-

under the guide of our engineer

-

Rotation speed (r/min):

-

1000/100

-

Advantage:

-

Low consumption,High capacity

-

Application:

-

cement & other

-

Installation:

-

Under Technical Guidance

-

Color:

-

Requestt

-

Keyword:

-

Rotary Kiln

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongji

-

Voltage:

-

220/380/440v

-

Power:

-

15-630kw

-

Dimension(L*W*H):

-

Production Capacity

-

Weight:

-

10 kg

-

Product name:

-

Small Scale Rotary Kiln Making Quick Active Lime Processing Plant

-

Fuel:

-

coal,mazut,gas etc

-

spare parts supply:

-

for the whole using life

-

Install:

-

under the guide of our engineer

-

Rotation speed (r/min):

-

1000/100

-

Advantage:

-

Low consumption,High capacity

-

Application:

-

cement & other

-

Installation:

-

Under Technical Guidance

-

Color:

-

Requestt

-

Keyword:

-

Rotary Kiln

Products Description

Product Application

Working Principle

The rotary kiln from china professional manufacture Hongji Group Machinery is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly around its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, the materials gradually move down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or 'firing pipe') which acts like a large burner. The fuel may be gas, oil or pulverized coal.

Product Paramenters

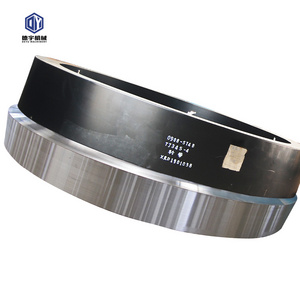

Product Showcase

Installation Site

Packaging & Shipping

|

Packaging Details:

|

Delivery Time:

|

|

We will load different sizes of packing according to different machine sizes, and the normal packing is in wooden cases. If exported to European countries, wood frame will be fumigation. If the container is too tight, we will use the PE film according to the customer's special requirements.

|

We are based on the actual needs of customers, to carry out tailor-made sales. By senior engineer to design scheme, after receipt of customer deposits began production, regardless of the size of the equipment we can deliver the goods in two weeks, delivered the balance after delivery.

|

Hot Searches