- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

as require

-

Weight:

-

9.5 KG

Quick Details

-

Production Capacity:

-

40 T/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Forui

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

as require

-

Weight:

-

9.5 KG

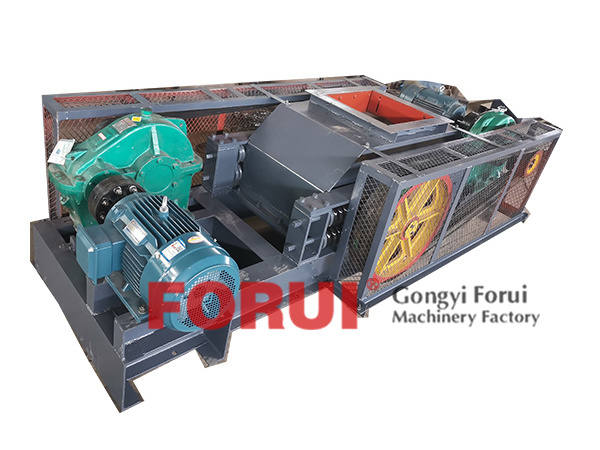

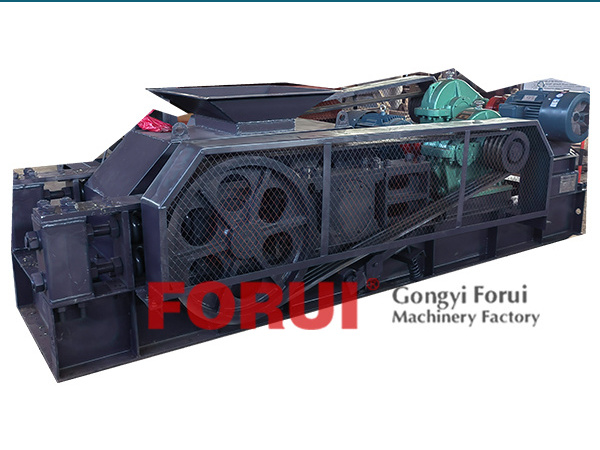

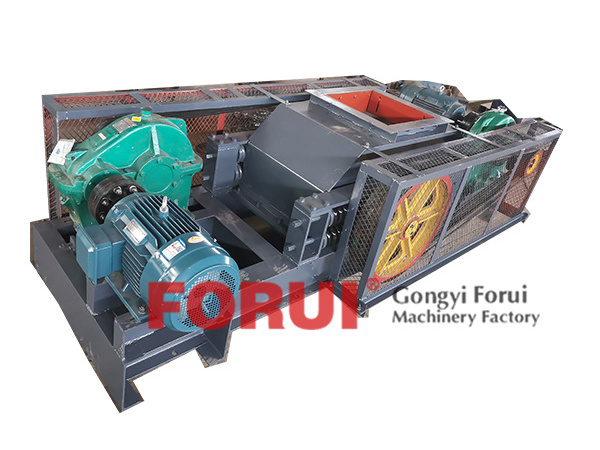

Product Overview

I

ntroduction

Roller crusher is also called double roll crusher, roller sand making machine. It uses two motors to drive two pairs of roller shaft to extrude and grind materials. Roller crusher suitable for: cement, chemical industry, electric power, mining, metallurgy, building materials, refractories, coal and other industries. It is suitable for medium and fine crushing of brittle block materials. Its feed size is large, the output size can be adjusted according to the actual situation. It can crush the material whose compressive strength is less than 160MPa.

Electric System

Drive System

Roller Bearing

Principle

The roller crusher is operated by two motors which drive two rollers. The crushing effect of roller crusher on materials is mainly extrusion and grinding. Mainly suitable for medium and fine crushing of medium hardness materials.

In order to get different granularity of the roller crusher, the size of the discharge hole must be adjustable. In order to

prevent the roller damage of the crusher, it is necessary to install a safety device. The movable roller shaft of the roller

crusher is supported by the pressure of spring.

In order to get different granularity of the roller crusher, the size of the discharge hole must be adjustable. In order to

prevent the roller damage of the crusher, it is necessary to install a safety device. The movable roller shaft of the roller

crusher is supported by the pressure of spring.

Under the normal working condition, the spring force is sufficient to overcome the crushing force needed by the broken material. Shim with different thickness can be placed between the frame and the movable bearing. By changing the number of shim, the width of the discharge opening between the two rollers can be adjusted, so as to meet the requirements of different product granularity. When there is a very hard material into the crushing chamber, the compression spring, the roller moves outward, the discharge port increases. After the material is discharged, the movable roller is reset under the action of spring pressure. This is the adjustment of the mechanical discharge port and overload protection device (safety device).

Flowsheet

Crushing Flowsheet

Raw Material -> Feeder -> Jaw Crusher -> Roller Crusher -> Screen -> Result

Successful Project

FEATURES AT A GLANCE

HIGH EFFICIENCY

LOW COST

EASY TO INSTALL

HIGH CAPACITY

LONG SERVICE LIFE

LIFETIME TECHNICAL SUPPORT

Specification

|

Model

|

Feeding Size

(mm)

|

Output Size

(mm) |

Capacity

(t/h) |

Power (kw)

|

Weight

(t) |

L * W * H (mm)

|

|

2PG400×250

|

<35

|

≤2-8

|

2-10

|

2×5.5

|

1.3

|

2150×980×800

|

|

2PG400×400

|

<35

|

≤2-8

|

5-12

|

2×7.5

|

2.3

|

2360×1100×800

|

|

2PG610×400

|

<65

|

≤2-20

|

5-20

|

2×15

|

3.9

|

3510×1420×1030

|

|

2PG750×500

|

<75

|

≤2-25

|

10-40

|

2×18.5

|

9.5

|

4210×1630×1260

|

|

2PG800×600

|

<80

|

≤2-25

|

12-45

|

2×22

|

10.8

|

4505×1780×1320

|

|

2PG1000×700

|

<100

|

≤3-30

|

20-65

|

2×30

|

14.9

|

5310×2175×1595

|

|

2PG1200×800

|

<120

|

≤3-35

|

35-80

|

2×37

|

25.5

|

6290×2270×1870

|

|

2PG1500×800

|

<130

|

≤3-45

|

50-120

|

2×75

|

33.7

|

7460×2410×2290

|

|

2PG1600×1000

|

<150

|

≤3-50

|

60-140

|

2×90

|

41.2

|

8220×2680×2475

|

Hot Searches