1.Rear stopper positioning control 2. Intelligent positioning function

3.One-way and two-way positioning function, effectively eliminate the lead screw clearance

4.Concession and material escape function

5. Automatic search reference point function

6.Parameter one-key backup and recovery function

7. Quick position teaching function

8.40 multi-step program storage space, each program has 25 work steps

9.power-off protection function

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

240 mm

-

Width of Working Table (mm):

-

120 mm

-

Dimension:

-

1700*950*1750

-

Place of Origin:

-

ANHUI,CHINA

-

Brand Name:

-

HANRUI

-

Year:

-

new

-

Weight (KG):

-

1200

-

Motor Power (kw):

-

4 kw

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

1600

-

Slider Stroke (mm):

-

100 mm

-

Throat Depth (mm):

-

240 mm

-

Width of Working Table (mm):

-

120 mm

-

Dimension:

-

1700*950*1750

-

Place of Origin:

-

ANHUI,CHINA

-

Brand Name:

-

HANRUI

-

Year:

-

new

-

Weight (KG):

-

1200

-

Motor Power (kw):

-

4 kw

Performance characteristics

Easy Bend B Series Hydraulic NC Press Brake Machine is our most popular model by volume and a true workhorse. The studies made on

the framework flections have allowed us to design a product that reacts in the most appropriate and responsive way to the

mechanical solicitations, therefore guaranteeing a stable structure, thus a higher precision in bending. This feature is even

enhanced by a system of manual crowning. Worth mentioning is also the possibility to add options and upgrades on the

configuration, at later stage.Constructed of high quality parts and offering serious reliability , Y-axis Torsion bar syncro

technology with high approach, bending and return speeds.

the framework flections have allowed us to design a product that reacts in the most appropriate and responsive way to the

mechanical solicitations, therefore guaranteeing a stable structure, thus a higher precision in bending. This feature is even

enhanced by a system of manual crowning. Worth mentioning is also the possibility to add options and upgrades on the

configuration, at later stage.Constructed of high quality parts and offering serious reliability , Y-axis Torsion bar syncro

technology with high approach, bending and return speeds.

|

Model

|

Nominal

Pressure

(kN)

|

Worktable length

(mm)

|

Distance

between

Housings

|

Throat

Depth

(mm)

|

Ram stroke

(mm)

|

Strokes

(min')

above

|

Open

height

(mm)

|

Main

motor

(kw)

|

Overall

Dimensions

L*W*H(mm)

|

|

WC67Y/K-30/1600

|

300

|

1600

|

1280

|

200

|

80

|

16

|

190

|

3

|

1700*900*1650

|

|

WC67Y/K-30/2000

|

300

|

2000

|

1280

|

200

|

80

|

18

|

190

|

3

|

1700*900*1650

|

|

WC67Y/K-40/2500

|

400

|

2500

|

1900

|

280

|

100

|

20

|

320

|

5.5

|

2600*1100*1900

|

|

WC67Y/K-63/2500

|

630

|

2500

|

2050

|

300

|

100

|

12

|

380

|

5.5

|

2605*1725*2355

|

|

WC67Y/K-63/3200

|

630

|

3200

|

2670

|

250

|

100

|

10

|

380

|

5.5

|

3300*1725*2355

|

|

WC67Y/K-80/2500

|

800

|

2500

|

2050

|

250

|

140

|

10

|

395

|

7.5

|

2605*1725*2355

|

|

WC67Y/K-80/3200

|

800

|

3200

|

2660

|

250

|

140

|

10

|

395

|

7.5

|

3300*1725*2405

|

|

WC67Y/K-100/2500

|

1000

|

2500

|

2050

|

320

|

140

|

8

|

395

|

7.5

|

2600*1800*2540

|

|

WC67Y/K-100/3200

|

1000

|

3200

|

2660

|

320

|

140

|

8

|

395

|

7.5

|

3290*1740*2400

|

|

WC67Y/K-100/4000

|

1000

|

4000

|

3060

|

320

|

140

|

8

|

395

|

7.5

|

4090*1740*2500

|

|

WC67Y/K-100/5000

|

1000

|

5000

|

3960

|

320

|

140

|

8

|

395

|

7.5

|

5100*1740*2800

|

|

WC67Y/K-125/3200

|

1250

|

3200

|

2510

|

320

|

140

|

8

|

395

|

7.5

|

3450*1740*2450

|

|

WC67Y/K-125/4000

|

1250

|

636104000

|

3610

|

320

|

140

|

8

|

395

|

7.5

|

4090*1740*2450

|

|

WC67Y/K-160/3200

|

1600

|

3200

|

2540

|

330

|

200

|

6

|

457

|

11

|

3280*1930*2800

|

|

WC67Y/K-160/4000

|

1600

|

4000

|

3140

|

330

|

200

|

6

|

457

|

11

|

4080*1930*2800

|

|

WC67Y/K-160/4500

|

1600

|

4500

|

3300

|

330

|

200

|

6

|

457

|

11

|

4580*1930*2800

|

|

WC67Y/K-200/4000

|

2000

|

4000

|

3140

|

330

|

200

|

3

|

457

|

11

|

4080*1930*2800

|

|

WC67Y/K-250/5000

|

2500

|

5000

|

3900

|

400

|

200

|

5

|

560

|

20

|

5550*1900*3100

|

|

WC67Y/K-300/3200

|

3000

|

3200

|

2500

|

400

|

250

|

3

|

630

|

19

|

3750*2200*3100

|

|

WC67Y/K-300/4000

|

3000

|

4000

|

3070

|

400

|

250

|

3

|

630

|

23

|

4550*2200*3300

|

|

WC67Y/K-300/5000

|

3000

|

5000

|

3900

|

400

|

250

|

3

|

630

|

26

|

5550*2200*3400

|

|

WC67Y/K-300/6000

|

3000

|

6000

|

4900

|

400

|

250

|

3

|

630

|

30

|

6550*2200*3500

|

|

WC67Y/K-400/4000

|

4000

|

4000

|

3000

|

400

|

300

|

2.5

|

770

|

26

|

4550*2600*3500

|

|

WC67Y/K-400/5000

|

4000

|

5000

|

3900

|

400

|

300

|

2.5

|

770

|

30

|

5550*2600*3700

|

|

WC67Y/K-400/6000

|

4000

|

6000

|

4900

|

400

|

300

|

2.5

|

770

|

36

|

6550*2600*3800

|

|

WC67Y/K-500/4000

|

5000

|

4000

|

3000

|

450

|

350

|

2.5

|

860

|

37

|

4550*2800*3700

|

|

WC67Y/K-500/5000

|

5000

|

5000

|

3900

|

450

|

350

|

2.5

|

860

|

46

|

5550*2800*3800

|

|

WC67Y/K-500/6000

|

5000

|

6000

|

4900

|

450

|

350

|

2.5

|

860

|

55

|

6500*2800*3800

|

|

WC67Y/K-600/6000

|

6000

|

6000

|

4900

|

450

|

350

|

2.5

|

860

|

60

|

6550*3000*4200

|

SHOW THE DETAILS

E21 system

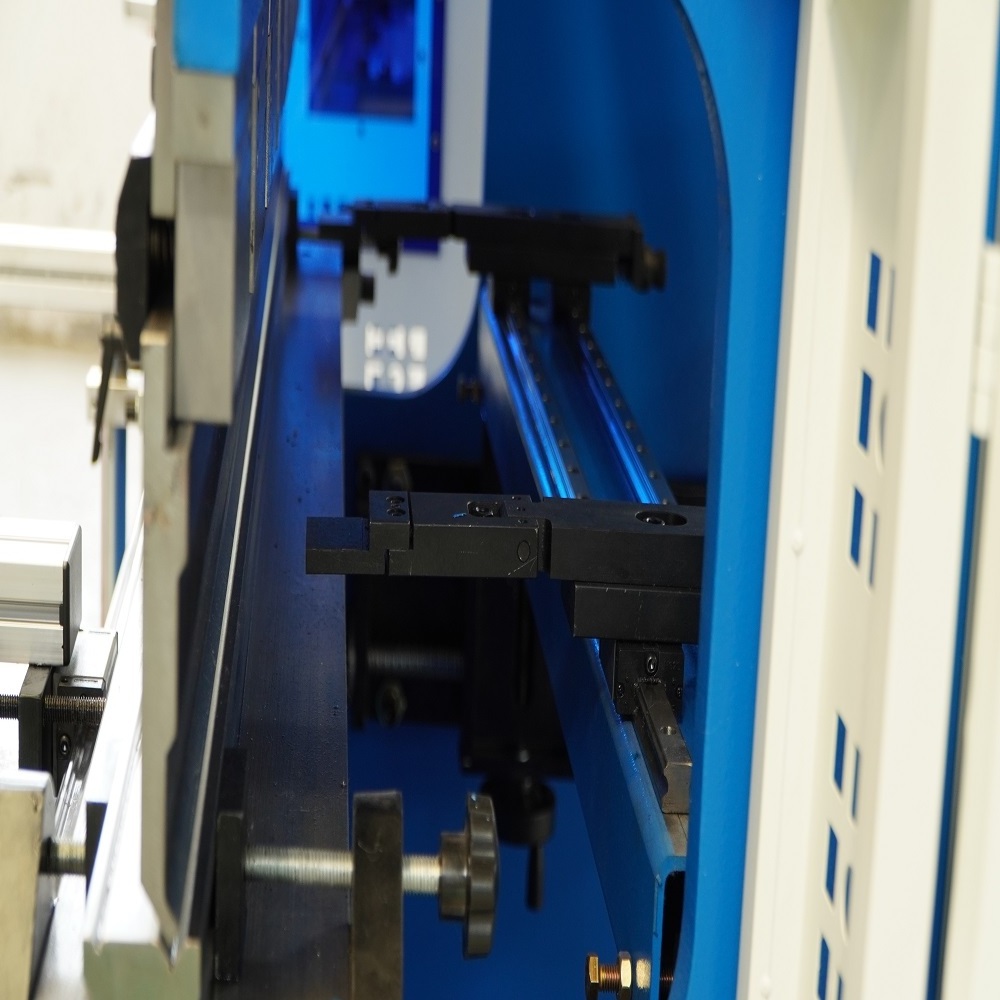

Fast Clampings

Standard double V lower die with different size and various shaped slots for choice ,convenient for exchanging dies,capable for

bending regular plates, with high cost performance CNC double-V die workbench,convenient for installation of segmented dies

bending regular plates, with high cost performance CNC double-V die workbench,convenient for installation of segmented dies

HYDRAULIC SYSTEM

Germany Bosch-Rexroth integrated hydreulic system block, hydraulic transmission with high reliablity, integrated hydreulic system

can effectively alleviate problems caused by leakag of hydraulic fluid.

can effectively alleviate problems caused by leakag of hydraulic fluid.

Backgauge

6 Axis CNC Backgauge ,including the R1 R2 ; X1 X2 ; Z1 Z2 ,can move up and down ; front and back , left and right , the fine

adjustment with high accuracy up to ± 0.02mm

adjustment with high accuracy up to ± 0.02mm

Mechanical Crowning Worktable

Through compensation, the angle of the workpiece is prevented from increasing in the full length range, the angle and linear accuracy of the bent workpiece are effectively improved.

Product display

Bending machine bending effect

A VIEW OF THE FACTORY

FAQ

Q: How to get a accurate quotation from us ?

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Hot Searches