- Product Details

- {{item.text}}

Quick Details

-

Inlet Diameter:

-

1250*500MM

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHD

-

Dimension(L*W*H):

-

12600*2600*3880mm

-

Weight (KG):

-

20000

-

Name:

-

Track chip machine

-

Raw material:

-

Bamboo,wood,wood pallet

-

Rotor Speed:

-

765RPM

-

Certificate:

-

CE ISO

-

Conveyor Length*Width:

-

5m* 1.2m

-

Discharge Height:

-

3800-4900MM

-

Capacity:

-

20-30t/h

-

Main diesel engine brand:

-

Weichai brand

-

Hydraulic Oil Tank:

-

300-630L

-

Feeding System:

-

Hydraulic Motor

Quick Details

-

Mill Granularity:

-

20-80mm

-

Number of Cutter:

-

12

-

Cutter Diameter:

-

800mm

-

Inlet Diameter:

-

1250*500MM

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHD

-

Dimension(L*W*H):

-

12600*2600*3880mm

-

Weight (KG):

-

20000

-

Name:

-

Track chip machine

-

Raw material:

-

Bamboo,wood,wood pallet

-

Rotor Speed:

-

765RPM

-

Certificate:

-

CE ISO

-

Conveyor Length*Width:

-

5m* 1.2m

-

Discharge Height:

-

3800-4900MM

-

Capacity:

-

20-30t/h

-

Main diesel engine brand:

-

Weichai brand

-

Hydraulic Oil Tank:

-

300-630L

-

Feeding System:

-

Hydraulic Motor

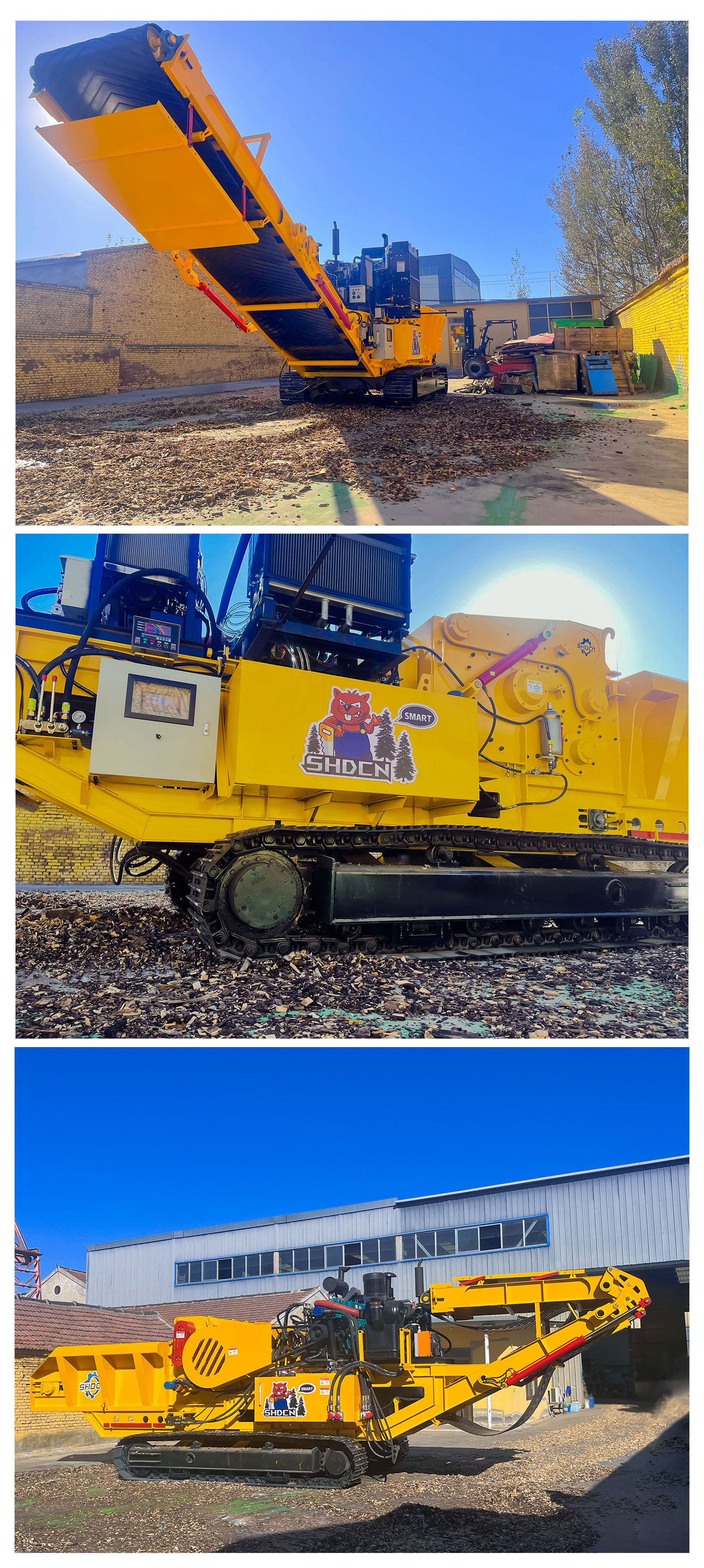

Crawler type wood crusher

Products Description

A crawler-type wood chipper is a specialized wood processing equipment mainly used to process wood, branches, bark and other wood raw materials into wood chips, wood flakes and other granular materials. It is widely used in wood processing, papermaking, biomass energy and other fields. It has the advantages of high efficiency, energy saving and environmental protection, and can greatly improve the efficiency of wood processing and reduce costs.

TECHNICAL PARAMETERS

|

Model

|

SHD 1300-600 Series Self-propelled Crawler Fully Hydraulic Wood Crusher

|

|

Feeding Inlet

|

1250*500mm

|

|

Capacity

|

20-30t/h

|

|

Rotor Diameter

|

800MM

|

|

Rotor Speed

|

765RPM

|

|

Knife Quantity

|

12 pieces

|

|

Conveyor Length*Width

|

5m* 1.2m

|

|

Wood Chips Size

|

20-80mm

|

|

Machine size

|

12600*2600*3880mm

|

|

Weight

|

20t

|

|

Chain Plate Width

|

1200MM

|

|

Chain Plate Length

|

3000MM

|

Product advantage

1.

The crushing power system of this equipment adopts our company's customized Weifang diesel engine, which has stable performance (low speed, high torque). The walking system adopts Yuchai diesel engine, which has stable quality and reliable performance

2.

The feeding chain plate conveyor, feeding roller, discharge conveyor, and crawler walking system use a gear pump as the power source, operate at low pressure, have a simple structure, and are easy to maintain

3.

The electronic control sensor system adopts major brands such as Siemens, Schneider, and Omron Electric, with stable and reliable quality

4.

The hydraulic control valve is self-developed by our company for this product: (combination of push rod and manual valve)

5.

The oil temperature sensor will monitor the temperature of the hydraulic oil in real time, and when the temperature is too low or too high, it will remind you in the form of a light

6.

The diesel fuel tank is equipped with an electric current level display (stable and reliable performance);

7.

Industrial display screen protection level: IP65, working environment temperature: -10 ℃ -55 ℃, working environment humidity: 10-90% RH (non condensing), vibration resistance: 10-25HZ (2G/30 minutes in X, Y, Z directions);

8.The front end adopts a strong magnetic roller to effectively remove iron containing substances from the wood chips;

Production Process

Company profile

We are Shanghangda Machinery Manufacturing Co., Ltd, the manufacturer was established in 1999, one of the first Chinese companies to initiate its own research capabilities in wood chipper and biomass pellet technology.

Shanghangda Products are specialists in the design and manufacture of high quality chip and wood pellet equipment ,has been the leading manufacturer of the highest quality wood chipper and wood pellet machine available on the market today, products are exported to Europe, America, Africa, Southeast Asia and other countries around the world We got creditable good praise from our customers in many years.

Our Services

1. Install and debug equipment for customers according to the situation

2 Guide customers to operate equipment skillfully and produce safely

3 Patiently explain the daily maintenance of the equipment and the troubleshooting of common faults for customers

4 Try to solve difficult problems for customers as soon as possible

5 Customer technicians are welcome to come to our company for instruction and study at any time

2 Guide customers to operate equipment skillfully and produce safely

3 Patiently explain the daily maintenance of the equipment and the troubleshooting of common faults for customers

4 Try to solve difficult problems for customers as soon as possible

5 Customer technicians are welcome to come to our company for instruction and study at any time

CERTIFICATE

Hot Searches