- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Rotor, Screener, Hammer Slice

-

Voltage:

-

220V 380V

-

Power:

-

22kw

-

Dimension(L*W*H):

-

7000x1500x2000 mm

-

Weight (KG):

-

1100

-

Product name:

-

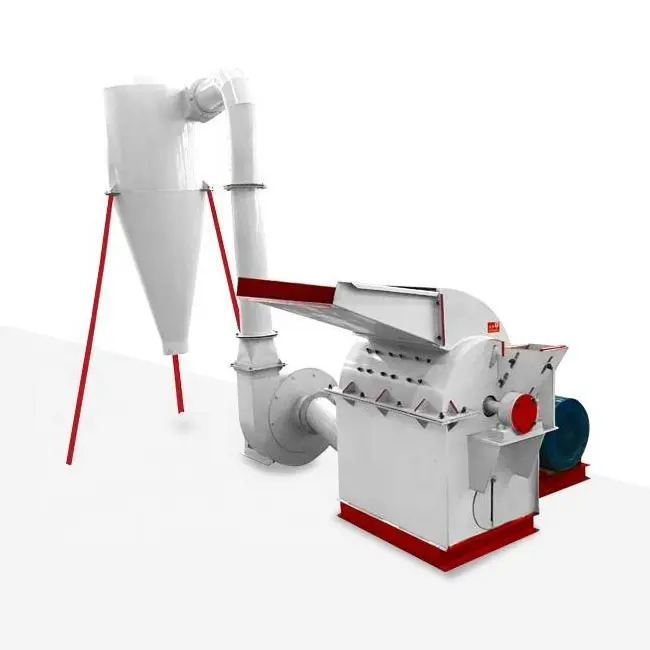

Wood hammer mill

-

Motor:

-

Siemens Motor

-

Color:

-

Customer Required

-

Type:

-

Hammer Mill

-

Application:

-

Wood sawdust, rice husk,wheat straw

-

Material moisture:

-

Moisture<30%

-

Spare parts:

-

Screen, hammers

-

Material of hammer:

-

Manganese steel

-

After-sales Service:

-

Provide video teaching

-

Sieve Screen:

-

2-10mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FH

-

Marketing Type:

-

New Product 2022

-

Core Components:

-

Rotor, Screener, Hammer Slice

-

Voltage:

-

220V 380V

-

Power:

-

22kw

-

Dimension(L*W*H):

-

7000x1500x2000 mm

-

Weight (KG):

-

1100

-

Product name:

-

Wood hammer mill

-

Motor:

-

Siemens Motor

-

Color:

-

Customer Required

-

Type:

-

Hammer Mill

-

Application:

-

Wood sawdust, rice husk,wheat straw

-

Material moisture:

-

Moisture<30%

-

Spare parts:

-

Screen, hammers

-

Material of hammer:

-

Manganese steel

-

After-sales Service:

-

Provide video teaching

-

Sieve Screen:

-

2-10mm

Wood crusher is mainly used for processing branches, wood chips, waste, wood, raw materials such as bamboo, more suitable for use in edible fungi culture in the sawdust machine processing. Wood crusher is mainly composed of the upper body, lower body, the rotor assembly, screen pieces, feeding device, rack and so on six parts, airframe and rotor assemblies together from the crushing chamber, it is the main working parts.

|

Model

|

Power(KW)

|

Yield(T)

|

Weight(T)

|

Hammer of the number (slice)

|

|

FHQ65-27

|

22

|

0.5-2

|

1.1

|

24

|

|

FHQ65-55

|

37-45

|

1-3

|

1.5

|

48

|

|

FHQ65-75

|

55-75

|

3-5

|

1.9

|

72

|

|

FHQ65-100

|

90-110

|

4-6

|

2.3

|

90

|

|

FHQ130-50

|

132-160

|

5-6

|

5.3

|

108

|

|

FHQ130-100

|

160-220

|

6-8

|

6.8

|

160

|

1.Machine all parts processed by CNC, ensure steady and safety;

2.All of our rotors inside of the hammer crusher pass an accurate dynamic balancing test, resulting in low noise and smooth running;

3.The grinding camber is of semicircular shape, and the bottom is fitted with double grinding structure, further improving the capacity with evener particle size;

4.The spare parts hammers and mesh are high alloy wear-resistant materials;

5.Can adjust the space between the rotor and mesh, so that the final grinding size can be adjusted during 0.5-20mm;

2.All of our rotors inside of the hammer crusher pass an accurate dynamic balancing test, resulting in low noise and smooth running;

3.The grinding camber is of semicircular shape, and the bottom is fitted with double grinding structure, further improving the capacity with evener particle size;

4.The spare parts hammers and mesh are high alloy wear-resistant materials;

5.Can adjust the space between the rotor and mesh, so that the final grinding size can be adjusted during 0.5-20mm;

6.Simple construction, convenient operation, high efficiency and low power consumption.

Q: Is OEM available?

A: Yes, OEM and customization are available. Also, we can provide label printing service.

Q: Are samples available?

A: Free samples are available while freight is chargeable.

Q: What is your payment terms?

A: T/T,L/C,Paypal for different circumstances.

Q: What's your delivery way?

A: Express delivery, air shipping, sea shipping are available for your request.

Q: What's your delivery time?

A: Usual delivery time is 5-10days after recieving the advance payment;

For the customized product, 15-30 days after receiving the advance payment.

Hot Searches