The whole system consists of the following parts:

1.High speed servo control weighing machine

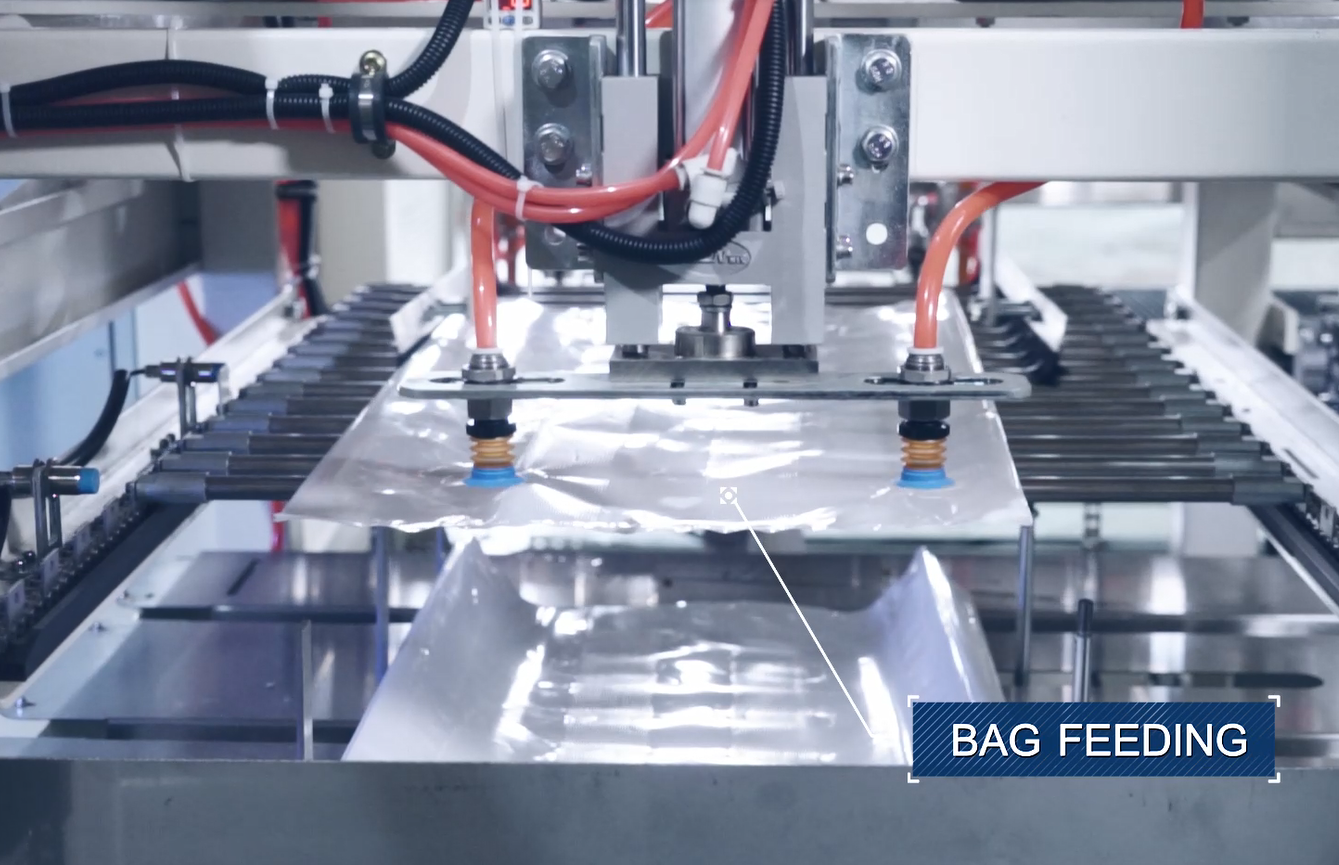

2.Auto bag feeding and packing machine with electric control box

3.Automatic Stitching /sewing/heating/paper taping sealing machine(NEWLONG stitching head)

4.Plat form(painted steel or stainless steel 304)

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000

-

Place of Origin:

-

China

-

Product name:

-

Auto bagging machine

-

After-sales Service Provided:

-

Field Installation Commissioning

-

Automaticity:

-

Fully Auto

-

Advantage:

-

High Packing Capacity

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Sealing

-

Packaging Type:

-

Bags, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

1000

-

Place of Origin:

-

China

-

Product name:

-

Auto bagging machine

-

After-sales Service Provided:

-

Field Installation Commissioning

-

Automaticity:

-

Fully Auto

-

Advantage:

-

High Packing Capacity

|

Model

|

ZDK25

|

ZDK50

|

|

|

Maximum speed

|

550-650 bags/h or high speed model 800-1000bags/h

|

|

|

|

Bag size

|

L*W:(630-830)*(350-450)mm

|

L*W:(800-1100)*(450-650)mm

|

|

|

Weighing range

|

10-25kg/bag

|

25-50kg/bag

|

|

|

Bag storage capacity

|

100-200

|

|

|

|

Control method

|

PLC

|

|

|

|

Power supply

|

three-phase four (five) wire system, 380V, 50HZ, 7KW

|

|

|

|

Air source used

|

clean, dry, oil-free and dust-free, 0.5-0.7MPa, 8000NL/Min

|

|

|

|

Sealing method

|

heat sealing inner bag + seam outer bag

|

|

|

|

Packing bag type

|

Premade open-mouth bag

|

|

|

|

Packing bag material

|

paper bag, polyethylene coated paper bag, PE inner film paper bag, aluminum foil paper bag, PE bag, polypropylene fiber bag,Coated

fiber bag, PE inner film fiber bag |

|

|

|

Bag specifications

|

non-standard

|

|

|

|

Packing bag shape

|

flat bag, flat bottom bag

|

|

|

25kg Bagging Machine

Working processing from 25kg Raw material supplying, auto weighing filling , auto bag feeding, auto open mouth bagging, auto bag moving,auto bag sealing , finsihed products output.

Brief Introduction:

lThe open mouth bagging machine is widely applied in food industry(rice, beans,sugar,corns ), chemical industry, feed, grain, seed ,salt, sugar, pet foods and other Industries with paper bag,palstic bag. etc.

lAutomatic supplying bags can be high-speed and continuous.

lEvery execution unit includes control & safety device to make the equipment run automatically and continuously.

lThe motor manufactured by SEW make the equipment more efficient.

lThis machine has functions such as automatic weighing, bag feeding, automatic filling, automatic bag delivery, and automatic sealing. It can be linked with equipment to process all kinds of granular and flake materials to realize unmanned production of large packaging.

1. The open mouth bagging machine filling weight range from 10-25kg or 25-50kg for each bag, and can supply about 550-650 bags/h or high speed model 800-1000bags/h.

2. Automatic supplying bags can be high-speed and continuous.

3. Every execution unit includes control & safety device to make the equipment run automatically and continuously.

4. The motor manufactured by SEW make the equipment more efficient.

The equipment is widely applied in chemical industry, feed, grain, seed ,salt, sugar, pet foods and other Industries with paper bag, plastic bag, etc.

Bag Supplying Machine→Take Empty Bag→Open Empty Bag→Bag Clamping and Feeding Mechanism→Bag Bottom Flapping Mechanism→Bag Horizontal Moving & Pocket Mouth Clamping Mechanism→Standing Bag Conveyor→Auto bag folding and sewing→Finished bag

Q1: Are you a factory or a trading company?

A1:We are the factory with manufacturing and self-supporting import and export rights for more than 25 years.

Q2: How to choose suitable packaging machine?

A2:Need to provide your material pictures and requirements, such as packaging speed, packaging weight, bag type and bag size.

Q3: How about the payment way?

A3:Payment can be T/T, L/C etc. we can provide FOB, CNF, CIF term by sea.

Q4: How to ensure the quality of the machine?

A4:We usually delivery the machine after successful inspection in our factory. We have our own quality control department,before the delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q5: How to install the equipment?

A5:We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Hot Searches