- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

WINTRUSTEK

-

Color:

-

Gray

-

Density:

-

3.10/cm3

-

Compressive Strength:

-

2500 MPa

-

Flexural Strength:

-

380 MPa

-

Max Working Temperature:

-

1400°C

Quick Details

-

Material:

-

Silicon Carbide

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

customized

-

Brand Name:

-

WINTRUSTEK

-

Color:

-

Gray

-

Density:

-

3.10/cm3

-

Compressive Strength:

-

2500 MPa

-

Flexural Strength:

-

380 MPa

-

Max Working Temperature:

-

1400°C

Product Description

Hot Sale Products

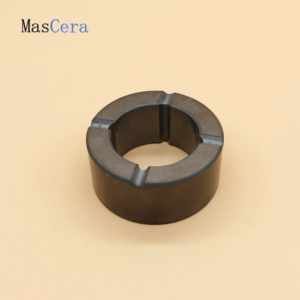

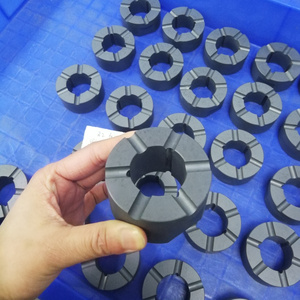

Details Images

Specification

|

- Product Name:

|

Customized Wear Resistant / Silicon Carbide / SiC Ceramic Seal Ring

|

|

- Material:

|

SiC / Silicon Carbide

|

|

- Typical Characteristics:

|

1. High Hardness, Out Standing Wear Resistance

2. High Strength Over A Wide Temperature Range 3. Excellent Thermal Shock Resistance 4. Excellent Oxidation Resistance 5. Very Low Friction Coefficient 6. Low Thermal Expansion and High Thermal Conductivity |

|

- Typical Applications:

|

1. Mechanical Seal

2. Heat Exchanger 3. Armour Plate 4. Ball Vlave Parts 5. Pump Components 6. Semiconductor 7. Metallurgical Engineering 8. Fixed and Moving Turbine Components |

|

Properties / Material

|

SSiC

|

|

Sintering Method

|

Pressureless Sintering

|

|

Density (g/cm

3

)

|

3.10

|

|

Purity (%)

|

>98

|

|

Shore's Hardness

|

>115

|

|

Modulus Of Elasticity(@25°C, GPa)

|

>410

|

|

Flexural Strength (MPa)

|

380

|

|

Compressive Strength (MPa)

|

2500

|

|

Thermal Expansion Coefficient (10

-6

/K)

|

4.2

|

|

Max Working Temperature (°C)

|

1400

|

About US

WINTRUSTEK is a leading manufacturer specialized in technical ceramics since 2014.Over the years we have been committed to the research, design, production and marketing by providing a wide range of advanced ceramic solutions for industries that request outstanding material performance to overcome extreme working conditions.

Our ceramic materials include:- Aluminium Oxide - Zirconium Oxide - Beryllium Oxide- Aluminium Nitride- Boron Nitride- Silicon Nitride- Silicon Carbide- Boron Carbide- MacorOur customers choose to cooperate with us based on our leading technology, profession, and commitment to the industries we serve.

Our ceramic materials include:- Aluminium Oxide - Zirconium Oxide - Beryllium Oxide- Aluminium Nitride- Boron Nitride- Silicon Nitride- Silicon Carbide- Boron Carbide- MacorOur customers choose to cooperate with us based on our leading technology, profession, and commitment to the industries we serve.

Wintrustek's long-term mission is to improve the performance of the advanced materials while maintaining our focus on client satisfaction by providing the highest quality products and first-class service.

Packing & Delivery

FAQ

Q1: How to make sure the exact material I need?

please tell us your requests on material performance and your specific application, according to which we will offer you the most suitable material.

Q2: Do you accept customized production based our specification?

Yes, we offer OEM and ODM service. Just send us your drawing if you have it. If you don’t have a drawing, just tell us your idea, o

ur professional designers will make it out.

Q3: What is the MOQ?

We don't have limit to the quantity.

Q4: Can you guarantee the product?

Yes, we promise to provide quality assurance for all products, inspect according to your drawings and issue an inspection report. If you are not satisfied with our product quality or service, please feel free to give us feedback.

Hot Searches