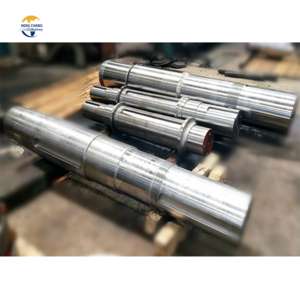

We can forging from 300-50000kgs for one piece.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

alloy steel

-

Torque Capacity:

-

Custom

-

Model Number:

-

OEM

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wangli

-

Product name:

-

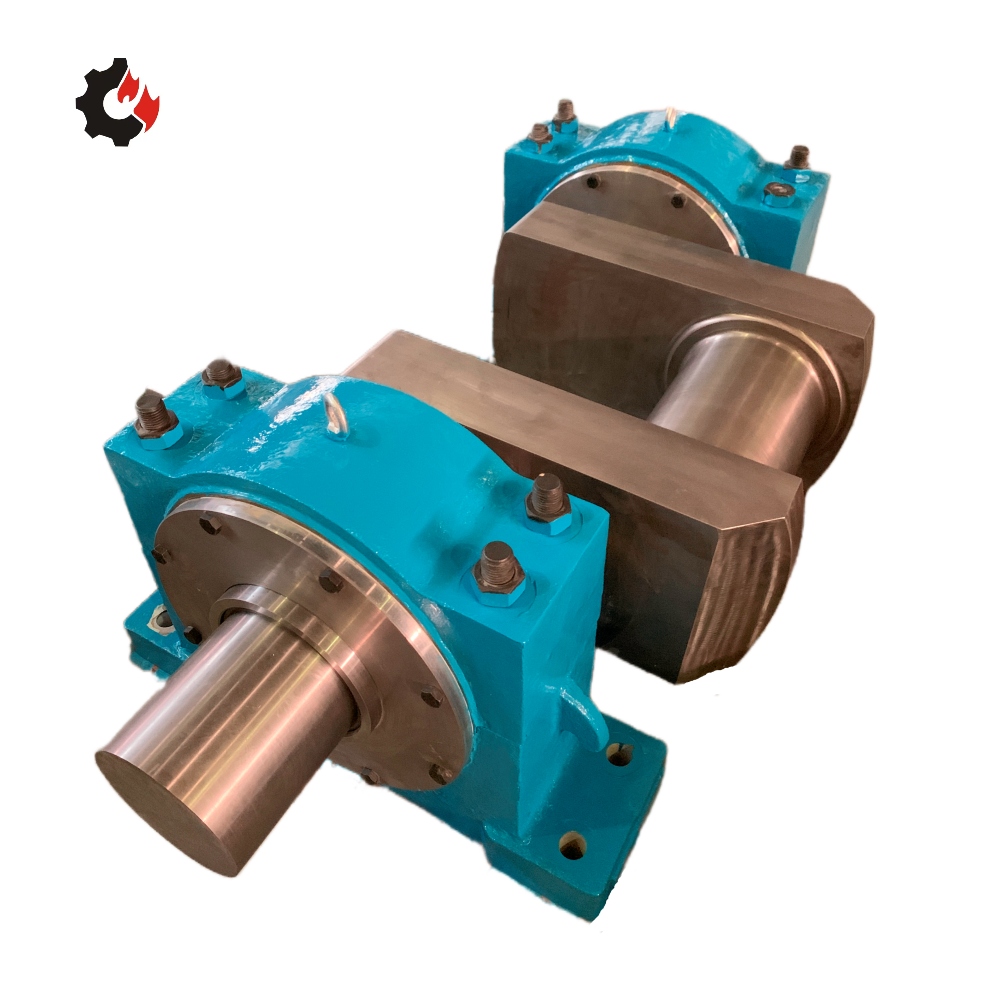

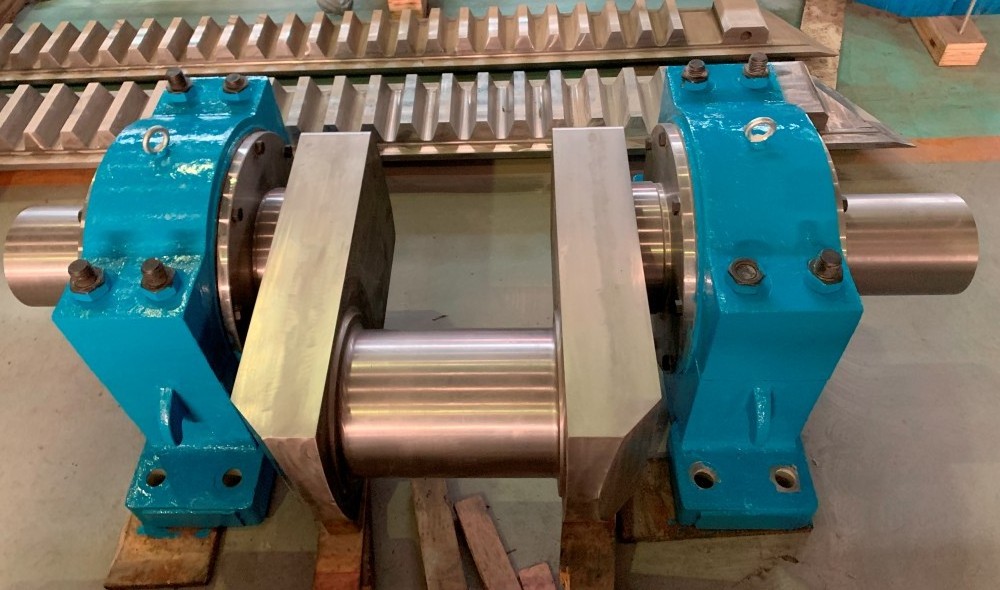

large eccentric shaft

-

Quality:

-

High-Quality

-

Application:

-

Dragline Excavator

-

Certificate:

-

ISO

-

Tolerance:

-

0.01mm

-

Color:

-

Custom

-

MOQ:

-

1 Piece

-

Packing:

-

Custom

-

Heat treatment:

-

Q+T

-

Length:

-

Min:1000mm

Quick Details

-

Weight (KG):

-

1500

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

eccentric shaft

-

Material:

-

alloy steel

-

Torque Capacity:

-

Custom

-

Model Number:

-

OEM

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wangli

-

Product name:

-

large eccentric shaft

-

Quality:

-

High-Quality

-

Application:

-

Dragline Excavator

-

Certificate:

-

ISO

-

Tolerance:

-

0.01mm

-

Color:

-

Custom

-

MOQ:

-

1 Piece

-

Packing:

-

Custom

-

Heat treatment:

-

Q+T

-

Length:

-

Min:1000mm

Why Choose Us

--Luoyang Wangli Heavy Machinery Co., LTD is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts. The company has obtained

more than 30 national patents

, and its main products include spare parts for construction machinery(pull-shovel, electric shovel, driving), cement machinery spare parts(kiln tyre, bearing, roller shaft,liner plate and so on), large modulus gear (shaft), hot forging die, large non-standard machinery products.

--Luoyang Wangli Heavy Machinery Co.,Ltd is High-Tech Enterprise , Luoyang Large Mold Heat Treatment Engineering Technology Center.

--Technical Supports for Material

Technical supports for new material and new manufacturing process according to customers working conditions in order to improve lifespan of machinery parts. we have twelve senior engineers.

-- Military Quality

Participating in the designing and manufacturing rail for the largest radio telescope in Asia and forging dies for the airplane for the military industry.

----OEM Machinery Parts Supplier

After over 30 years of development,various large non-standard machinery products have been already sold to the whole China and exported to 50+ countries including the United States, Russia, Germany, Spain,India,etc.

--Luoyang Wangli Heavy Machinery Co.,Ltd is High-Tech Enterprise , Luoyang Large Mold Heat Treatment Engineering Technology Center.

--Technical Supports for Material

Technical supports for new material and new manufacturing process according to customers working conditions in order to improve lifespan of machinery parts. we have twelve senior engineers.

-- Military Quality

Participating in the designing and manufacturing rail for the largest radio telescope in Asia and forging dies for the airplane for the military industry.

----OEM Machinery Parts Supplier

After over 30 years of development,various large non-standard machinery products have been already sold to the whole China and exported to 50+ countries including the United States, Russia, Germany, Spain,India,etc.

Products Description

|

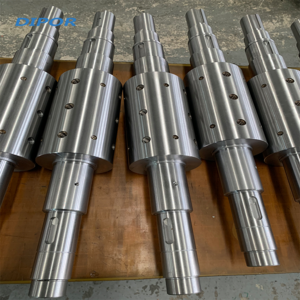

Mining Machinery Alloy Steel Long Large Forging Crank Shaft

|

|

|

|

|||

|

Specification

|

Nonstandard

|

Roller

|

Ring

|

|||

|

Material

|

34CrNiMo6, 42CrMo

|

SC45

|

SC45

|

|||

|

Tolerance

|

+/- 0.01MM

|

|

|

|||

|

Surface

|

Grinding

|

|

|

|||

|

As customers' required and drawings

|

|

|

|

|||

Product Inspection

The precision can arrive 0.01mm

The hardness can arrive 240-280HB

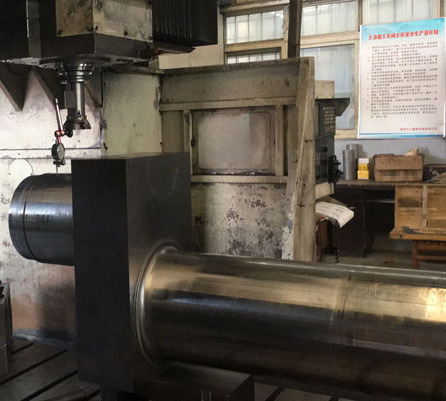

Diameter Checking for Large Forging Crank Shaft

Packing and Delivery

About Us

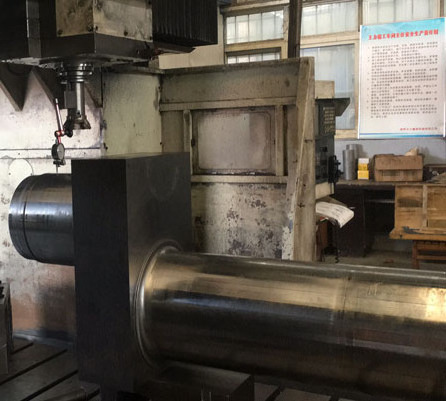

1. Over 30 years experiences in manufacturing precision large nonstandard heavy machinery spare parts.

2. Having five s

tandardized workshops, which are

hoisting hook

150 Tons.

3. Vertical well electric furnace heat treatment - Max. DIA is 6 meter, Max. Depth 9 meters.

4. Twelve senior engineers in forging/ heat treatment fields.

5. OEM & ODM can provided, s

pecialized e-commerce and technical team can provide online service.

We can do the Maximum forging weight 400 Tons for one per piece. The casting blank can arrive 30 Tons for per piece.

Advantage of our Heat Treatment:

- Professional, specific furnace, single-minded

- Vertical pit furnace,keep the temperature uniformity during heating,+/-1℃

- Small deformation,little oxide layer,reduce material cost

- Different materials can be cooled at the best speed

- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

Our Team

Marketing team

I can't travel around the world, let my products for me to see the beautiful world

R&D department

We believe: material is the skeleton of the machine, process design is the thought of the machine, CNC machining is the essence of the machine, heat treatment is the soul of the machine

Customer Visit

Hot Searches