- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

1200*1200*1600MM

-

Weight:

-

550, 550kg

-

Function:

-

Make Nuts

-

After sales Service Provided:

-

24 Hours Provide Technical Support

-

Max. drilling diameter:

-

32mm

-

Tapping stroke:

-

45mm/65mm

-

Spindle motor:

-

0.75kw/1.5kw/2.2kw

-

Clamping method:

-

Pneumatic and hydraulic clamping

-

Dimension:

-

120*120*160cm

-

Spindle Speed(r/min):

-

80-1450r/min

-

Product name:

-

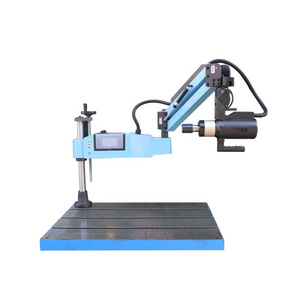

Nut Vertical Drilling Hex Nuts And Screw Threading Tapping Machine

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Marketing Type:

-

Hot Product 2021

-

Brand Name:

-

bobo

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

1200*1200*1600MM

-

Weight:

-

550, 550kg

-

Function:

-

Make Nuts

-

After sales Service Provided:

-

24 Hours Provide Technical Support

-

Max. drilling diameter:

-

32mm

-

Tapping stroke:

-

45mm/65mm

-

Spindle motor:

-

0.75kw/1.5kw/2.2kw

-

Clamping method:

-

Pneumatic and hydraulic clamping

-

Dimension:

-

120*120*160cm

-

Spindle Speed(r/min):

-

80-1450r/min

-

Product name:

-

Nut Vertical Drilling Hex Nuts And Screw Threading Tapping Machine

Product Description

Multi Functions Nut Automatic Vertical Drilling Advanced Hex Nuts And Screw Threading Tapping Machine

★ Features

1. The equipment is equipped as standard: automatic shutdown without material, automatic shutdown alarm function when the tap is broken.

2. Adopt PLC control, use color touch screen to realize man-machine dialogue, convenient and fast parameter setting, convenient operation, automatic alarm and shutdown in case of failure.

3. Good stability, low investment, high efficiency, high precision, large quantity and short cost recovery period.

4. All actions are controlled by software, and the equipment parameters can be set flexibly, which is convenient for function adjustment and technical upgrade.

5. The transmission system is precise and concise, the work is more stable, and the maintenance is more convenient. The failure rate is extremely low and the power consumption of the equipment is low.

6. It is convenient to replace the fixture and can be used for a variety of similar products to share this equipment.

7. The whole equipment is fully automated, and one person can operate multiple equipments at the same time.

★ Details

✔ Adopt high-precision infrared laser sensor to detect tap (waterproof and oil-proof) tap wear and tear, and automatically stop and alarm.

✔ Blind hole detection is standard, and the automatic shutdown alarm of the reverse material equipment occurs.

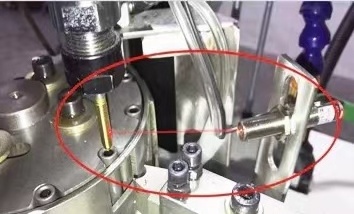

✔ The gear-type equal-pitch automatic tapping machine head is used to pass the thread, and the same degree and verticality of the thread are guaranteed.

✔ The clamping cylinder uses an enlarged adjustable stroke cylinder to ensure that the product can be clamped and not damaged.

✔ The equipment rack is equipped with fixed bolts to ensure the stability of the machine.

✔ Reasonable design of the material receiving mechanism ensures that all the material receiving boxes are qualified products.

★ Main Technical Data

|

NO.

|

Item

|

Parameter

|

|

1

|

Tapping ability

|

M1-M32 (Model optional)

|

|

2

|

Spindle speed

|

80-1450R/min

|

|

3

|

Feeding method

|

Stainless steel vibrating plate

|

|

4

|

Feed mode

|

Servo motor/gear pitc

|

|

5

|

Tapping stroke

|

45mm/65mm

|

|

6

|

Spindle motor

|

0.75kw/1.5kw/2.2kw

|

|

7

|

Clamping method

|

Pneumatic/hydraulic clamping

|

|

8

|

Body weight

|

550kg

|

|

9

|

Dimensions

|

1200*1200*1600mm

|

Product packaging

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Hot Searches