- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Plugin speed:

-

0.55s/Piece

-

Plug-in precision:

-

±0.03mm

-

Motion accuracy:

-

0.001/pulse

-

PCB size:

-

50*50mm-380*280mm

-

Air pressure:

-

5-6kg/cm2

-

Dimension:

-

1950*1200*1530mm

-

Weight:

-

1500kg

-

Terminal thickness:

-

≥0.6mm≤1.2mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Minderhightech

-

Weight (KG):

-

1500

-

Marketing Type:

-

Hot Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Plugin speed:

-

0.55s/Piece

-

Plug-in precision:

-

±0.03mm

-

Motion accuracy:

-

0.001/pulse

-

PCB size:

-

50*50mm-380*280mm

-

Air pressure:

-

5-6kg/cm2

-

Dimension:

-

1950*1200*1530mm

-

Weight:

-

1500kg

-

Terminal thickness:

-

≥0.6mm≤1.2mm

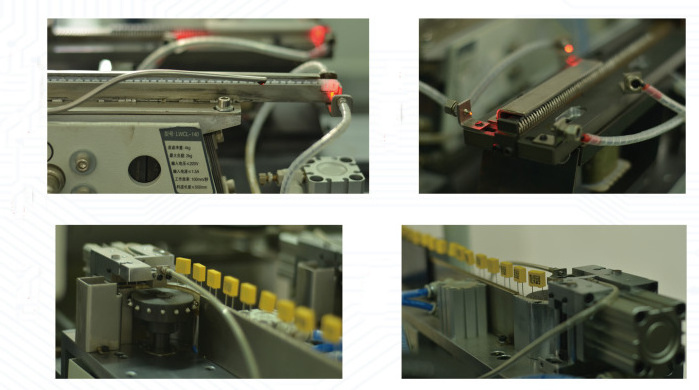

Introduction

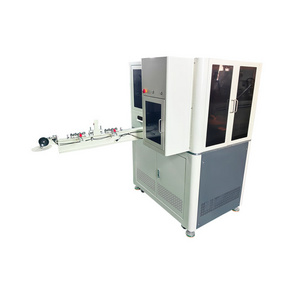

Bulk Terminal plug in machine automatically inserts various terminal components into the PCB according to the set program. It has the fixed tail function and the detection function to achieve high speed, high precision and high stable insertion effect.

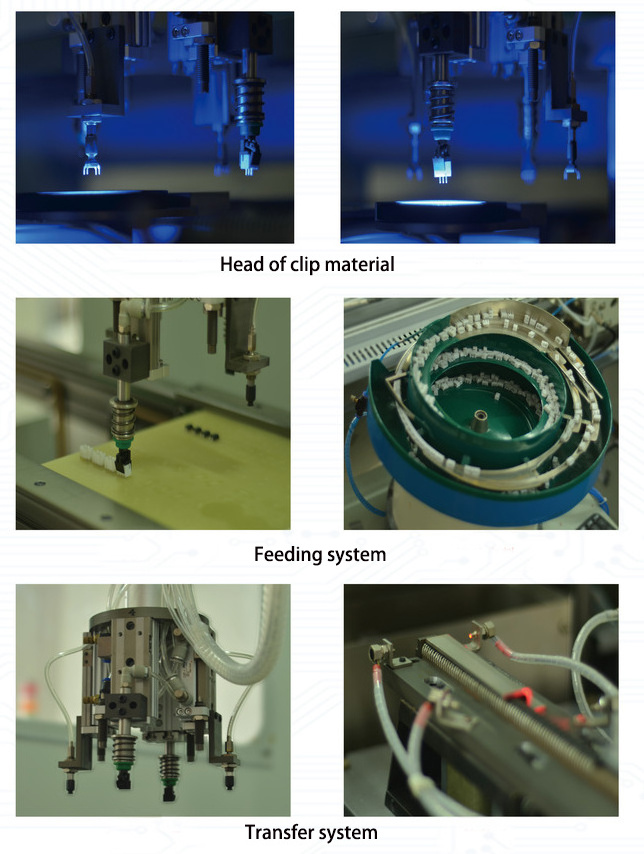

Operation system:

production data, management data, device parameters, editing program, all I/O signal diagnosis in Windows environment can be completed on the host, the interface is user-friendly, the device profile is efficient, and the operation is simple.

Visual System:

The industrial-specific high-definition camera and the self-developed vision correction software form a vision system. The deviation between the PCB hole position and the programmed input coordinates can be quickly and automatically calibrated to match all the coordinates with the actual PCB hole position, ensuring the plug-in accuracy and greatly improving the programming efficiency.

Plug in speed:

0.7 seconds / piece, equipped with Panasonic AC servo drive, high speed, low noise, smooth motion

Missing parts detection:

When the missing part is inserted, the missing part detection can be realized and a supplementary insertion function can be provided.

Important Parts Brand

01.Servo motor adopts Japanese Panasonic brand

02.Sending board, feeder system motor adopts Oriental brand

03.Pneumatic components adopt Taiwan Airtic brand

04.The lead screw adopts the Japanese THK brand

05.Camera system uses CGimagetech brand (5 million pixels)

06.Photoelectric sensor adopts SUNX brand of Japan

07.The main parts are made of Japanese mold steel

Characteristic

1).

This machine is mainly used for large components, special-shaped components and some

originals that cannot be inserted in the existing market plug-in machines.

2).This machine is a special-shaped plug-in device consisting of feeding structure, plug-in robot,

cutting foot bending, feeding mechanism and controller.

3).Each motion mechanism uses a high-precision servo mechanism and camera sensing to ensure the

stability and accuracy of the machine.

4).Man-machine interface control device: mainly for operating the touch screen through the program

written in the PLC to start and stop the machine according to the set processing sequence, and to set

and modify the processing parameters.

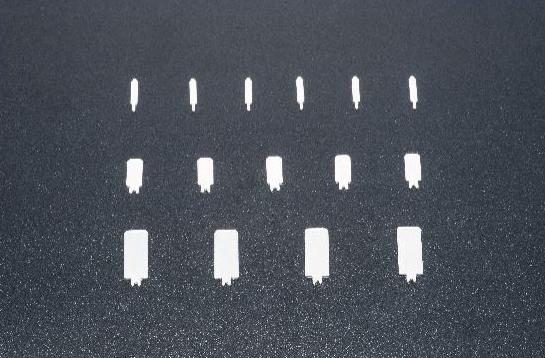

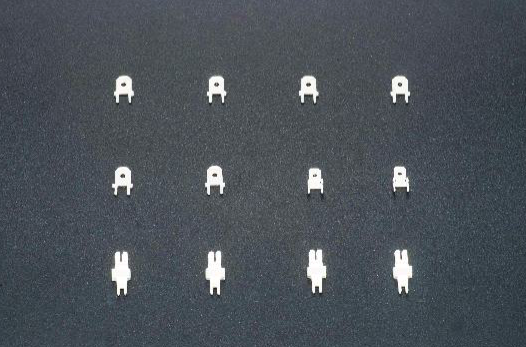

| Components |

Terminal,maximum size 10mm widh

22mm high |

| Plugin speed | 0.55s/Piece |

|

Loading and unloading

PCB time |

3s |

| Component packaging | Bulk |

| Loadable PCB size |

Maximum 380*280mm;

Minimum 50*50mm (Customizable) |

|

Number of plug-in

header |

1-4, can be used for terminal of different specifications. |

| Terminal thickness | ≥0.6mm≤1.2mm |

| PCB board requirements |

Positioning hole

The aperture is larger than the end of the component. |

| Insertion mode | Can be set 0,±90° |

|

Distance between

components |

2mm |

|

Component direction

detection |

Bottom mold detecting element foot |

| Terminal vertical error | ≤0.8 |

| Control System |

Independent research and development control system

Industrial computer + motion control |

| Display system | 17-inch color LCD |

| Feeding system | Vibrating plate,feeder |

| Motion accuracy | 0.001/pulse |

| Motion system | Panasonic servo controller, motor |

|

Programming

function |

Online visual programming

Visual correction Easy EXCEL process |

| Data input |

USB interface import

Manual entry |

|

communication

interface |

RS232C |

| Power supply |

220V/AC

50/60Hz,2KVA |

| Air pressure | 5-6kg/cm2 |

| Noise | ≤75db |

| Ambient temperature | 10℃-30℃ |

| Ambient humidity | 30%-70% |

| Air consumption | 0.63m3/min |

| Dimension | 1950*1200*1530mm |

| Weight | 1500kg |

Details:

Application:

Professional export packaging to ensure the safety of goods delivered: