- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

180kg-4350kg

-

Size:

-

1840*1120*800

-

Power:

-

0.2-5.9kw

-

Weight (KG):

-

1000 kg

-

Certificate:

-

ISO 9000, CE Certificate

-

Type:

-

Screw Type

-

Application:

-

Sewage Treatment

-

Operation:

-

Fulll Automatic

-

Motor:

-

Nissei, Nord, Sew/Customize

-

Service life:

-

>15years

-

DS Treating Capacity:

-

4 - 1768kg-ds/h

-

Inlet Solid Concentration:

-

0.20%-5.00%

-

Outlet Solid Concentration:

-

18% - 23%

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Water Master

-

Material:

-

plyood case, SS304/SS316L

-

Weight:

-

180kg-4350kg

-

Size:

-

1840*1120*800

-

Power:

-

0.2-5.9kw

-

Weight (KG):

-

1000 kg

-

Certificate:

-

ISO 9000, CE Certificate

-

Type:

-

Screw Type

-

Application:

-

Sewage Treatment

-

Operation:

-

Fulll Automatic

-

Motor:

-

Nissei, Nord, Sew/Customize

-

Service life:

-

>15years

-

DS Treating Capacity:

-

4 - 1768kg-ds/h

-

Inlet Solid Concentration:

-

0.20%-5.00%

-

Outlet Solid Concentration:

-

18% - 23%

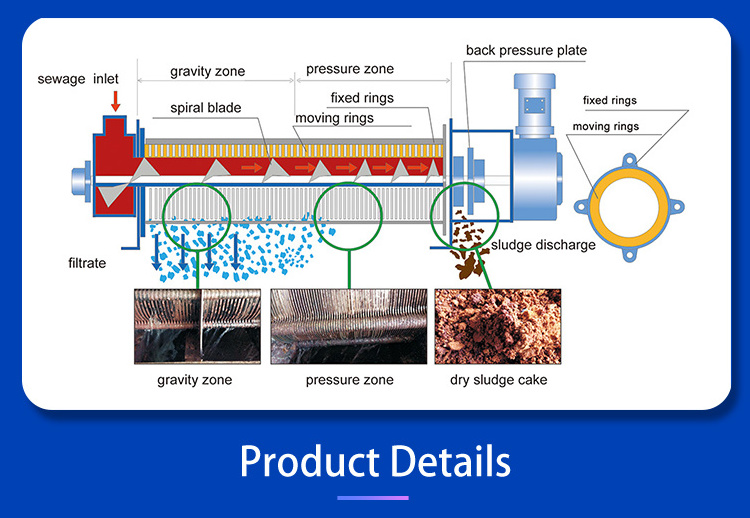

The screw type sludge dewatering machine is a kind of water treatment system, which is widely used in municipal wastewater treatment engineering, petrochemical, light industry, chemical fiber, paper making, leather and other industries. The conditioned sludge flows into the filter zones from the flocculation tank and is pushed forward to the discharging end.With the gaps between the thread of the shaft is getting even narrower,the pressure on the sludge is getting higher and higher.Then the water is separated from the sludge and flows out from the gaps between the moving rings and fixed rings.The movement of the moving rings will clean the gaps between moving and fixed rings and prevent the machine from blockage.The filtered sludge cakes will be pushed forward by the shaft and finally discharged from the end.

|

Type

|

Raw wastewater/

Waste actived sludge/Chemically precipitated sludge

|

|

Dissolved-air sludge

|

|

Mixed raw sludge

|

||

|

Sludge concentration(TS)

|

0.2%

|

1%

|

2%

|

5%

|

3%

|

||

|

WMDS-131

|

~4kg-DS/h(~2.0m³/h)

|

~6kg-DS/h(~0.6m³/h)

|

~10kg-DS/h(~0.5m³/h)

|

~20kg-DS/h(~0.4m³/h)

|

~26kg-DS/h(~0.87m³/h)

|

||

|

WMDS-132

|

~8kg-DS/h(~4.0m³/h)

|

~12kg-DS/h(~1.2m³/h)

|

~20kg-DS/h(~1.0m³/h)

|

~40kg-DS/h(~0.5m³/h)

|

~52kg-DS/h(~1.73m³/h)

|

||

|

WMDS-133

|

~12kg-DS/h(~6.0m³/h)

|

~18kg-DS/h(~1.8m³/h)

|

~30kg-DS/h(~1.5m³/h)

|

~60kg-DS/h(~1.2m³/h)

|

~72kg-DS/h(~2.61m³/h)

|

||

|

WMDS-201

|

~8kg-DS/h(~4.0m³/h)

|

~12kg-DS/h(~1.2m³/h)

|

~20kg-DS/h(~1.0m³/h)

|

~40kg-DS/h(~0.8m³/h)

|

~52kg-DS/h(~1.73m³/h)

|

||

|

WMDS-202

|

~16kg-DS/h(~8.0m³/h)

|

~24kg-DS/h(~2.4m³/h)

|

~40kg-DS/h(~2.0m³/h)

|

~80kg-DS/h(~1.6m³/h)

|

~104kg-DS/h(~3.47m³/h)

|

||

|

WMDS-203

|

~24kg-DS/h(~12.0m³/h)

|

~36kg-DS/h(~3.6m³/h)

|

~60kg-DS/h(~3.0m³/h)

|

~120kg-DS/h(~2.4m³/h)

|

~156kg-DS/h(~5.20m³/h)

|

||

|

WMDS-301

|

~20kg-DS/h(~10.0m³/h)

|

~30kg-DS/h(~3.0m³/h)

|

~50kg-DS/h(~2.5m³/h)

|

~100kg-DS/h(~2.0m³/h)

|

~130kg-DS/h(~4.33m³/h)

|

||

|

WMDS-302

|

~40kg-DS/h(~20.0m³/h)

|

~60kg-DS/h(~6.0m³/h)

|

~100kg-DS/h(~5.0m³/h)

|

~200kg-DS/h(~4.0m³/h)

|

~260kg-DS/h(~8.67m³/h)

|

||

|

WMDS-303

|

~60kg-DS/h(~30.0m³/h)

|

~90kg-DS/h(~9.0m³/h)

|

~150kg-DS/h(~7.5m³/h)

|

~300kg-DS/h(~6.0m³/h)

|

~390kg-DS/h(~13.0m³/h)

|

||

|

WMDS-304

|

~80kg-DS/h(~40.0m³/h)

|

~120kg-DS/h(~12.0m³/h)

|

~200kg-DS/h(~10.0m³/h)

|

~400kg-DS/h(~8.0m³/h)

|

~520kg-DS/h(~17.3m³/h)

|

||

|

WMDS-351

|

~40kg-DS/h(~20.0m³/h)

|

~60kg-DS/h(~6.0m³/h)

|

~100kg-DS/h(~5.0m³/h)

|

~200kg-DS/h(~4.0m³/h)

|

~260kg-DS/h(~8.67m³/h)

|

||

|

WMDS-352

|

~80kg-DS/h(~40.0m³/h)

|

~120kg-DS/h(~12.0m³/h)

|

~200kg-DS/h(~10.0m³/h)

|

~400kg-DS/h(~8.0m³/h)

|

~520kg-DS/h(~17.3m³/h)

|

||

|

WMDS-353

|

~120kg-DS/h(~60.0m³/h)

|

~180kg-DS/h(~18.0m³/h)

|

~300kg-DS/h(~15.0m³/h)

|

~600kg-DS/h(~12.0m³/h)

|

~780kg-DS/h(~26.0m³/h)

|

||

|

WMDS-401

|

~70kg-DS/h(~35.0m³/h)

|

~100kg-DS/h(~10m³/h)

|

~170kg-DS/h(~8.5m³/h)

|

~340kg-DS/h(~6.5m³/h)

|

~442kg-DS/h(~16.0m³/h)

|

||

|

WMDS-402

|

~135kg-DS/h(~67.5m³/h)

|

~200kg-DS/h(~20.0m³/h)

|

~340kg-DS/h(~17.0m³/h)

|

~680kg-DS/h(~13.6m³/h)

|

~884kg-DS/h(~29.5m³/h)

|

||

|

WMDS-403

|

~200kg-DS/h(~100m³/h)

|

~300kg-DS/h(~30.0m³/h)

|

~510kg-DS/h(~25.5m³/h)

|

~1020kg-DS/h(~20.4m³/h)

|

~1326kg-DS/h(~44.2m³/h)

|

||

Exclusive pre-thickening device enables a wide solid concentration ranging from 3000mg/l to 50000mg/l

Fixed and moving plates replace filter cloth, self-cleaning, clog-free, easy to handle oily sludge

Low running speed, low noise, low power consumption, 1 /8 of Belt Press and 1 /20 of centrifuge

Less capital construction cost, more excellent working performance

Fully automatic control, Easy operation and simple maintenance

Hot Searches