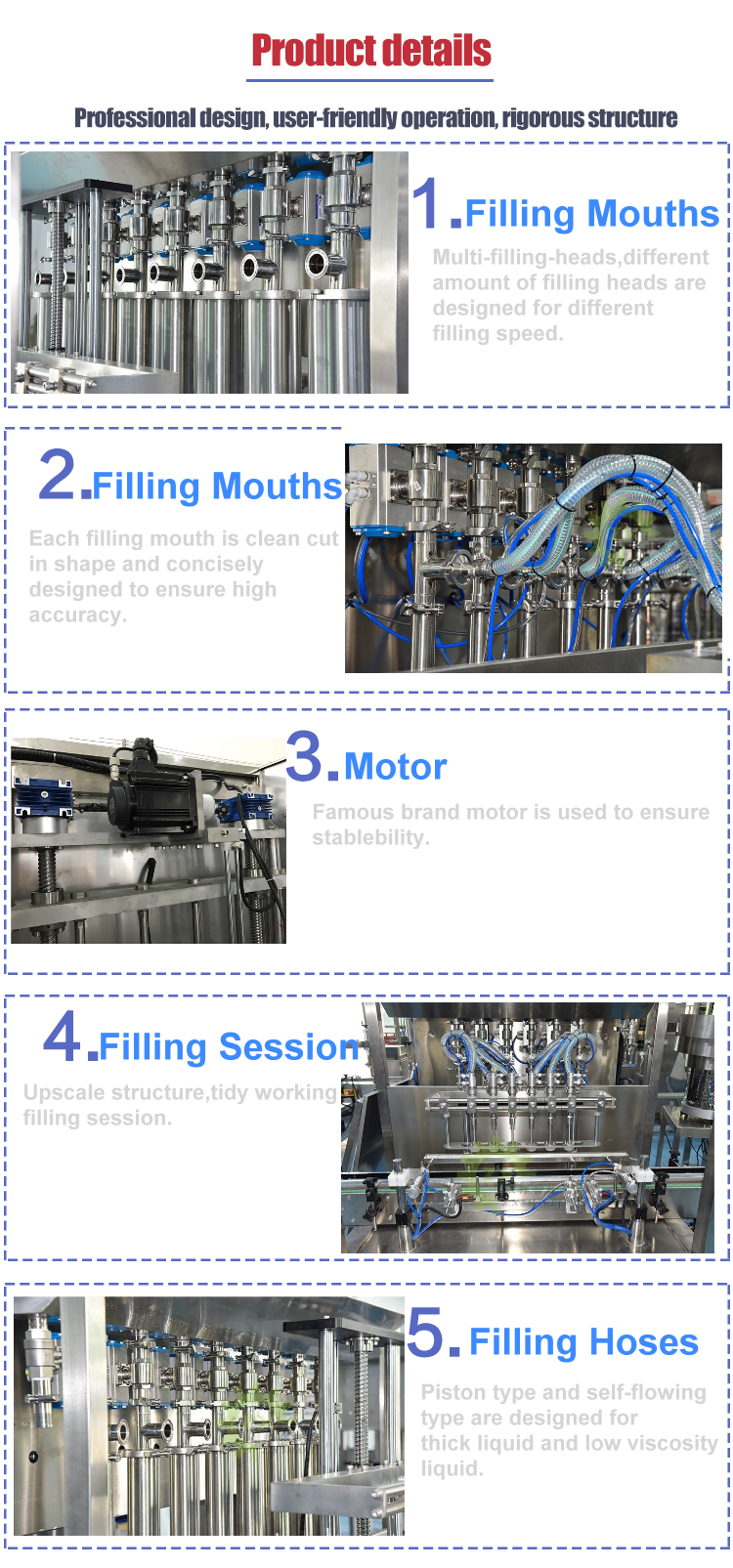

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V 0.4KW 50Hz

-

Place of Origin:

-

Guangdong, China (Mainland)

-

Brand Name:

-

XTIME

-

Dimension(L*W*H):

-

2740*1080*1800mm

-

Weight:

-

500 KG

-

Product name:

-

Liquid filling machine

-

Material:

-

Stainless steel

-

Filling speed:

-

High speed

-

Color:

-

Sliver

-

Filling nozzles:

-

4/6/8/10/12 Nozzles

-

Processing Types:

-

filling machine

-

Suitable bottle:

-

plastic bottle

-

Bottle size:

-

customized

-

Keywords:

-

Bleach liquid filling capping machine

Quick Details

-

Machinery Capacity:

-

2000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V 0.4KW 50Hz

-

Place of Origin:

-

Guangdong, China (Mainland)

-

Brand Name:

-

XTIME

-

Dimension(L*W*H):

-

2740*1080*1800mm

-

Weight:

-

500 KG

-

Product name:

-

Liquid filling machine

-

Material:

-

Stainless steel

-

Filling speed:

-

High speed

-

Color:

-

Sliver

-

Filling nozzles:

-

4/6/8/10/12 Nozzles

-

Processing Types:

-

filling machine

-

Suitable bottle:

-

plastic bottle

-

Bottle size:

-

customized

-

Keywords:

-

Bleach liquid filling capping machine

Applying range:

Features:

1. The machine is suitable for connecting to a whole production line.

2. Quality is reliable, simple operation and durable,it is the ideal equipment for liquid filling.

3.Plastic screw cap/ Metal cap capping machine will be provided customizied design according to customer's product.

How to adjust the machine:

1. To replace different types of bottles, the mechanical position of the filling bottle cylinder, the filling bottle cylinder, the filling bottle electric eye, the filling bottle electric eye, the bottle cylinder and the filling nozzle must be adjusted.

2. Filling the bottle with the electric eye must be aligned with the bottleneck of the last bottle. That is, when the bottle is automatically run, the 8th bottle must be placed in the range of the electric eye to be filled into the bottle. The bottle is not cut until the time set by the “Pilling Time” (set in the “Parameter Setting” of the HMI) is reached before the electric eye.

3. Filling and filling the bottle electric eye is installed in the slightly right position of the cylinder of the bottle. When the bottle is started, the cylinder of the bottle is extended, and the cylinder of the filling bottle is retracted; after a number of bottles (which can be set in the “out of the bottle interval” of the human-machine interface), the bottle is retracted and the bottle is started. After all the bottles have gone out (after filling out the bottle electric eyes), the filling bottle cylinders are extended.

4. When filling the bottle and discharging the bottle, the electric eye must be counted in 8 numbers before proceeding to the next step. The user can observe whether the number of bottles and bottles is 8 in the automatic operation screen of the man-machine interface.

|

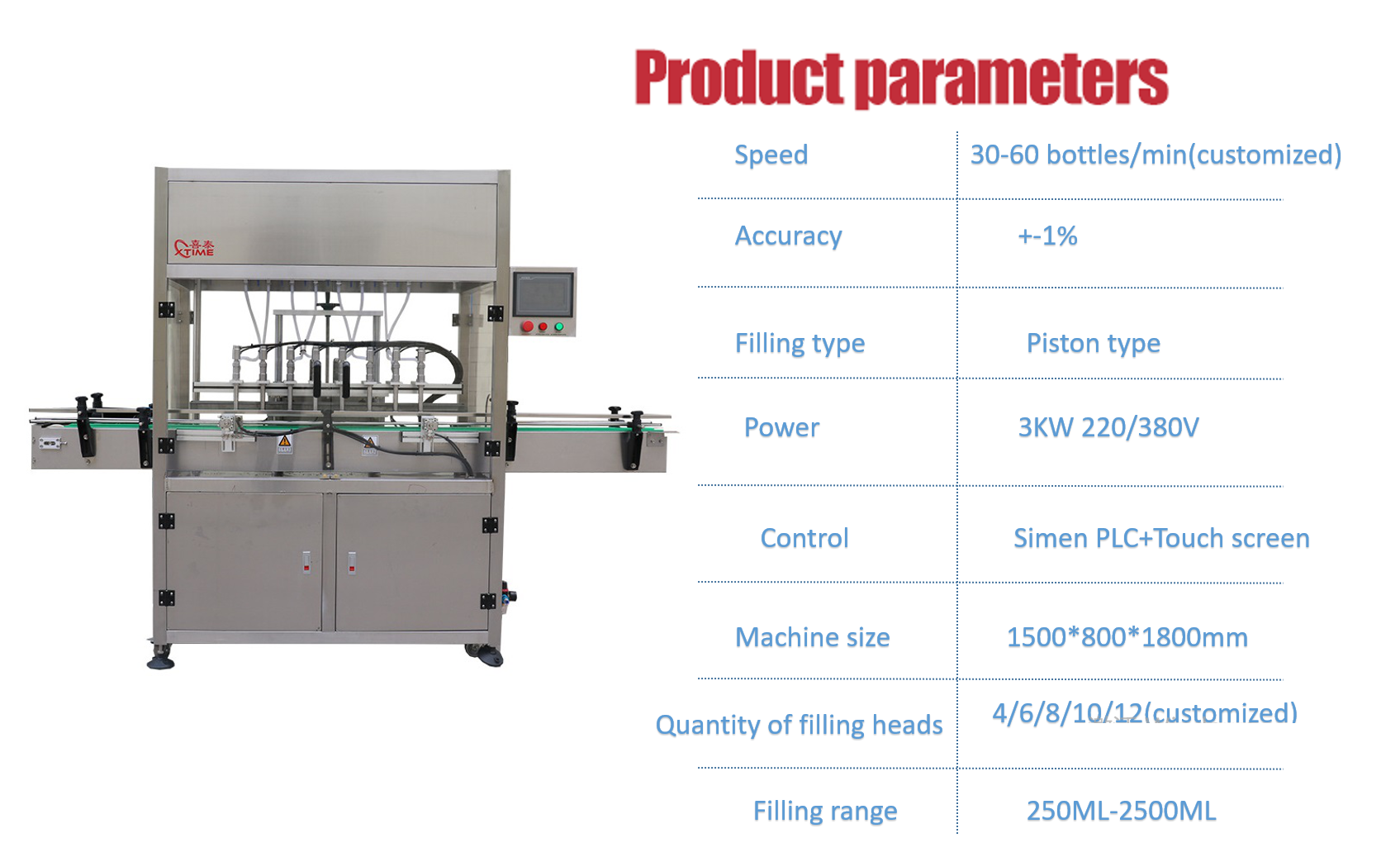

Speed

|

|

30-60 bottles/min(can be customized for different speed)

|

|

|

|||

|

≦±1%Accuracy

|

|

≦±1%

|

|

|

|||

|

Filling type

|

|

Piston type(Cylinder driving)

|

|

|

|||

|

Power

|

|

0.4KW 220V

|

|

|

|||

|

Control

|

|

Mitsubishi PLC+MCGS Touch screen

|

|

|

|||

|

Machine size

|

|

2740*1080*1800mm

|

|

|

|||

|

Quantity of filling heads

|

|

4/6/8/10/12(will be customized according to customer's filling speed requirement)

|

|

|

|||

|

Filling range

|

|

50-1000ml(can be customized for bigger volume)

|

|

|

|||