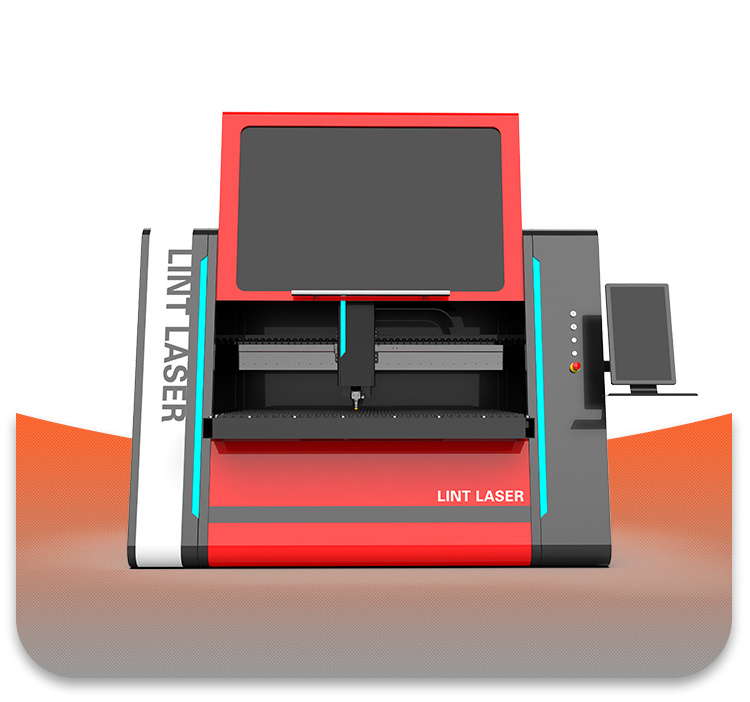

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-16mm

-

Control Software:

-

CYCUT

-

Place of Origin:

-

Shandong, China

-

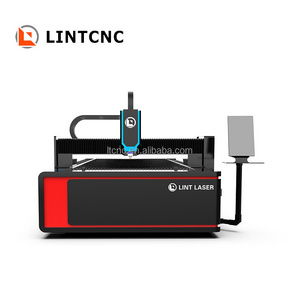

Brand Name:

-

LINTCNC

-

Weight (KG):

-

3000 KG

-

Core Components:

-

Laser head

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2022

-

Laser source:

-

Raycus RFL-C1000 1000W fiber laser power

-

Laser cutting head:

-

Raytools BT240S from Switzerland

-

Motors and Drivers:

-

FUJI servo motor & driver, X,Y axis 850W, Z axis 400W

-

Control system:

-

FSCUT1000 control system

-

Transmission:

-

X,Y axis with helical gear rack, Z axis with TBI ball screw

-

Reducer:

-

Japan imported SHIMPO reducer

-

Lubrication system:

-

One Touch Automatic lubrication system

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

35m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

0-16mm

-

Control Software:

-

CYCUT

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LINTCNC

-

Weight (KG):

-

3000 KG

-

Core Components:

-

Laser head

-

Certification:

-

CE

-

Marketing Type:

-

New Product 2022

-

Laser source:

-

Raycus RFL-C1000 1000W fiber laser power

-

Laser cutting head:

-

Raytools BT240S from Switzerland

-

Motors and Drivers:

-

FUJI servo motor & driver, X,Y axis 850W, Z axis 400W

-

Control system:

-

FSCUT1000 control system

-

Transmission:

-

X,Y axis with helical gear rack, Z axis with TBI ball screw

-

Reducer:

-

Japan imported SHIMPO reducer

-

Lubrication system:

-

One Touch Automatic lubrication system

Product Description

Main Features

Fiber laser power source options from 1000W to 3000W.

Light alloy beam (Y axis) to provide High dynamic performance. The optical path changes while the sheet remains still, thus the processing efficiency is high.

X, Y axis adopts high quality gear and rack, reduction gear, ensuring life and precision for a long time.

Imported Servo Motors. All motors are with Absolute Encoder.

The system is equipped with section dust collector to improve the working environment. The area beneath the cutting table is divided into several sections. During the cutting process, only the ducts directly beneath the cutting head are open for fume extraction. The ducts in the other sections remain closed to improve dust collection.

Applications for cutting stainless steel, carbon steel, aluminum, titanium, and most non-ferrous metals.

When processing, the laser only consumes electricity and doesn’t need extra gas(only auxiliary gas ),

bringing the minimum operation and maintenance costs.

bringing the minimum operation and maintenance costs.

Adopting semiconductor modular and redundancy design, without any optical glass in resonant cavity

and without start time, so it is in high stability and doesn’t need adjusting and maintaining, which saves the

costs and time. In this point, the traditional laser is not comparable.

and without start time, so it is in high stability and doesn’t need adjusting and maintaining, which saves the

costs and time. In this point, the traditional laser is not comparable.

The output wavelength of fiber laser is 1.06μm, which is a tenth of CO2 wavelength. The output beam is

in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great

power to cut and weld to make the lowest processing costs.

in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great

power to cut and weld to make the lowest processing costs.

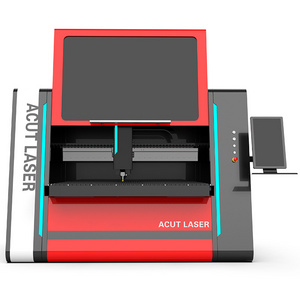

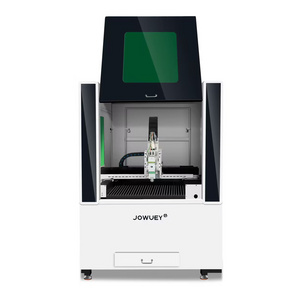

Specification

|

Model

|

LINT-1390S Fiber Laser Cutting Machine

|

|

Effective working area

|

(X=1300mm)*(Y=900mm)

|

|

Bed structure

|

High rigidity welded steel framework

|

|

Table surface

|

Blade table

|

|

Laser Source

|

Raycus RFL-C1000 1000W fiber laser power

|

|

Laser cutting head

|

Raytools BT240S from Switzerland

|

|

Guide Rail

|

25# Taiwan Hiwin square linear guide rail

|

|

Transmission

|

X,Y with helical gear rack, Z with TBI ball screw

|

|

Motors and drivers

|

FUJI servo motor & driver, X,Y axis 750W, Z axis 400W

|

|

Control system

|

Shanghai FSCUT1000 control system

|

|

Chiller

|

S&A, Dual Temperature Control

|

|

Reducer

|

Japan imported SHIMPO reducer

|

|

Lubrication system

|

One touch automatic lubrication system

|

|

Electronic Proportional Valve

|

SMC from Japan

|

|

Electronic Components

|

SCHNEDER, Omron

|

|

Max.iding speed

|

80m/min

|

Feedback and Sample

Application Industry

Stainless steel, carbon steel, alloy steel, spring steel, copper plate, aluminum plate, gold, silver, titanium and other plate products.

Widely used in advertising, high pressure / low voltage electrical cabinet production, textile machinery accessories, kitchen appliances, cars, machinery, elevators, electrical accessories, spring coil pieces, metro line parts and other industries.

Feedback

Please

click

and view the feedback video from our customers.

Our services

1.Guarantee:

3 years guarantee of the whole machine+1.5 years warranty for motor and spindle

2.Software issue:

Supply technical support for machine lifetime free.

3.Hardware issue:

Main parts(excluding the consumables) shall be replaced/ repaired free of charge if there is any problem during the warranty period.

4.Support online:

our engineer give 1 hours to solve question online.

5.Training in LINTCNC factory:

We are able to train your staff after placed order in our factory for free.

6.Oversea service:

We are able to send technician to your workshop to do the installation and training. You will need bear the

related costs. (flight,visa,hotel,training costs, etc.)

2.Software issue:

Supply technical support for machine lifetime free.

3.Hardware issue:

Main parts(excluding the consumables) shall be replaced/ repaired free of charge if there is any problem during the warranty period.

4.Support online:

our engineer give 1 hours to solve question online.

5.Training in LINTCNC factory:

We are able to train your staff after placed order in our factory for free.

6.Oversea service:

We are able to send technician to your workshop to do the installation and training. You will need bear the

related costs. (flight,visa,hotel,training costs, etc.)

Packing & Delivery

Hot Searches