- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhengzhou Sinoma

-

Power:

-

18.5-350 KW

-

Dimension(L*W*H):

-

Depending on Model

-

Weight:

-

80000 kg, 15-120tons(Depending on model)

-

Name:

-

Concrete Mixing Plant

-

Total Power:

-

60-350kw

-

Mixer machine Power:

-

18.5-110KW

-

Quality:

-

High Level

-

Spare parts supply:

-

Anytime

-

Advantages:

-

High Effiency

-

Color:

-

Customer Requirement

-

Installation:

-

Under Technical Guidance

-

Factory Visit:

-

Welcome

Quick Details

-

Machine Type:

-

Production line

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Sinoma

-

Power:

-

18.5-350 KW

-

Dimension(L*W*H):

-

Depending on Model

-

Weight:

-

80000 kg, 15-120tons(Depending on model)

-

Name:

-

Concrete Mixing Plant

-

Total Power:

-

60-350kw

-

Mixer machine Power:

-

18.5-110KW

-

Quality:

-

High Level

-

Spare parts supply:

-

Anytime

-

Advantages:

-

High Effiency

-

Color:

-

Customer Requirement

-

Installation:

-

Under Technical Guidance

-

Factory Visit:

-

Welcome

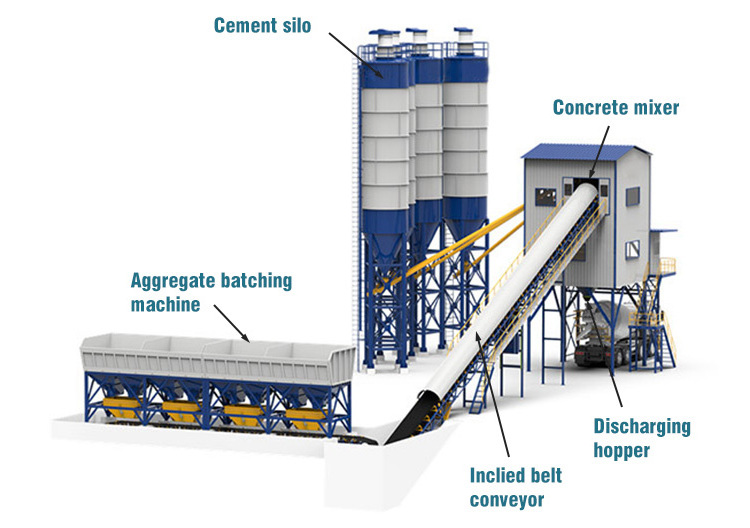

Product Description

Concrete mixing plant

is

developed by our company on the basis of adopting the world's sophisticated technologies, our concrete mixing plant has been widely sold in the domestic and overboard, as well as earned a perfect reputations in the construction field, we have dedicated in manufacturing concrete mixing plant, cement machinery and stone crushers for many years.Our c

oncrete mixing stations are widely used in construction projects, municipal projects, water conservancy projects, highway projects, bridge projects and other fields.

Details Images

Features

:

1. Modularization structure, easy to transport, install and debug.

2. Mixing system has the spiral mixing system, which has high efficiency. The scale board and mixing blades uses high-rigidity and high tenacity wearable case alloy steel, long working life.

3.

The aggregate lifting device can be frequency-controlled and speed-adjusted, operates smoothly and reliably.

4.

Intelligent control system, multiple guarantees, efficient management, computer synchronized production management control system, realizing free switching between fully automatic, semi-automatic and manual working modes, making production control more comfortable;

5. Liquid metering system, automatically realizes the functions of weighing overweight and supplementing underweight, making timely adjustments to improve measurement accuracy. It is equipped with admixture anti-leakage device to ensure the quality of concrete.

6. Accurate in metering.

Powder material metering system,

the whole metering system has a scientific structure design, which is not prone to material accumulation and weighing, and ensures metering accuracy.

7. Customized on demand. According to different needs, we provide customized overall dust removal solutions, host high-pressure cleaning systems, wet mix recovery systems, control systems, etc., to meets all your requirement.

Product Paramenters

|

Model

|

Theoretical Productivity

(m³/h)

|

Standard Height

(m)

|

Mixer Model (Mixer Output L)

|

Mixer Power

(kW)

|

Total Power

(kW)

|

Mixing cycle time(s)

|

|

HZS25

|

25

|

3.8m

|

JS750

|

18.5

|

≤60

|

60

|

|

HZS35

|

35

|

3.8m

|

JS750

|

30

|

≤60

|

60

|

|

HZS50

|

50

|

4.2m

|

JS1000

|

2×18.5

|

≤110

|

60

|

|

HZS60

|

60

|

4.2m

|

JS1000

|

2×18.5

|

≤110

|

60

|

|

HZS75

|

75

|

4.2m

|

JS1500

|

2×30

|

≤160

|

60

|

|

HZS90

|

90

|

4.2m

|

JS1500

|

2×30

|

≤160

|

60

|

|

HZS120

|

120

|

4.2m

|

JS2000

|

2×37

|

≤210

|

60

|

|

HZS180

|

180

|

4.2m

|

JS3000

|

2×55

|

≤270

|

60

|

|

HZS240

|

240

|

4.2m

|

JS4000

|

2×55

|

≤350

|

60

|

* Note:

The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

Application Areas&Materials

Advantage:

1. Safe and reliable.The mixing blades are made of high-chromium and high-manganese alloy wear-resistant materials, which are safe and reliable.

2. Automated control. All mixing stations are controlled by industrial computers, which can be controlled automatically or manually.

3. High measurement accuracy. Using precise sensors and inlet microcomputer control, aggregates, cement, water and admixtures are weighed individually or cumulatively using individual scales to fully ensure accurate measurement.

4. Strong stirring ability. The twin-shaft forced mixer has strong mixing capacity, uniform mixing and high productivity. It has good mixing effect on dry-hard, semi-dry-hard, plastic and various proportions of concrete.

Packing & Delivery

Hot Searches