- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ABM

-

Model Number:

-

Customized Shape Magnet

-

Coating:

-

Ni-Cu-Ni, Zn, Ni, Epoxy, Gold, Silver

-

Certification:

-

ROHS, TS16949, QS9000

-

Product Name:

-

half sphere remote control heavy magnets with magnetic screw

-

Size:

-

Customized Size

-

Usage:

-

Generator Motor/Magnetic Pump

-

Sample:

-

Freight Collect

-

Magnetism direction:

-

Thickness

-

Material:

-

Sintered Neodymium-Iron-Boron

Quick Details

-

Tolerance:

-

0.05mm-.0.1mm, 0.05mm ~ 0.1mm

-

Grade:

-

Sintered Neodymium-Iron-Boron, N30-N52, M, H, SH, UH, EH, AH

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ABM

-

Model Number:

-

Customized Shape Magnet

-

Coating:

-

Ni-Cu-Ni, Zn, Ni, Epoxy, Gold, Silver

-

Certification:

-

ROHS, TS16949, QS9000

-

Product Name:

-

half sphere remote control heavy magnets with magnetic screw

-

Size:

-

Customized Size

-

Usage:

-

Generator Motor/Magnetic Pump

-

Sample:

-

Freight Collect

-

Magnetism direction:

-

Thickness

-

Material:

-

Sintered Neodymium-Iron-Boron

✔Characteristics

Higher magnetic properties

Br:

11000-14500 Gs, Hci:

11000-30000 Oe

, BHmax:35-50MGOe

Lower temperature coefficient : maximum working temperature range:80-230 degree C

Higher corrosion resistant after coating Salt spray testing:24-72Hours

Coating Ni,Ni-Cu-Ni,Zn,Ag,Au,epoxy,parylene and other special coating

The magnet dimensions(drawing provided if available);

The grade of material and coating;

The working temperature of magnets;

The application of magnets;

|

Magnet Material

|

Neodymium Iron Boron (NdFeB, Neo)

|

|

Grade

|

N30-N52, M, H, SH, UH, EH, AH

|

|

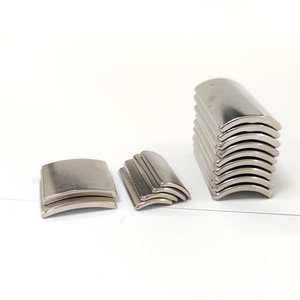

Shape

|

Customized Shape

|

|

Certification

|

ROHS, TS16949, QS9000

|

|

Tolerance

|

0.05mm ~ 0.1mm

|

|

Maximum Operation Temperature

|

80 °C - 230°C according to magnet material

|

|

Sample

|

Freight Collect

|

|

Magnetisation Direction

|

Axial / Diametrical

|

|

Specifications

|

1. Powerful Permanent Magnet

2. High quality & best price

3. High working temperature

4. Good corrosion resistance

|

Higher corrosion resistant after coating

Ni,Ni-Cu-Ni,Zn,Ag,Au,epoxy,parylene and other special coating

Salt spray testing:24-72Hours

Orientation and Magnetizing pattern

Multi-poles on face alone axial,axial and Diameter cross magmetization and other special magnetizing pattern.

Grade M for working temperature 100 degree C and below

Grade H for working temperature 120 degree C and below

Grade SH for working temperature 150 degree C and below

Grade UH for working temperature 180 degree C and below

Grade EH for working temperature 200 degree C and below

Grade AH for working temperature 220 degree C and below

Magnet will be packed with spacer for easy seprating and protecting.

Magnet will be plastic vacuum encapsulating for protecting.

Final carton size is 36x29x16cm having 8 small white boxes.

Foam separator and galvanized iron box to protect magnet and acting as magnetic shielding.

Providing complete stimulation and testing in order to ensure products' reliabality.

>> ABM

Magnetics focusing on the NdFeB magnets design and manufacturing over 20 years. We focus on effective quality assurance system to ensure best quality.

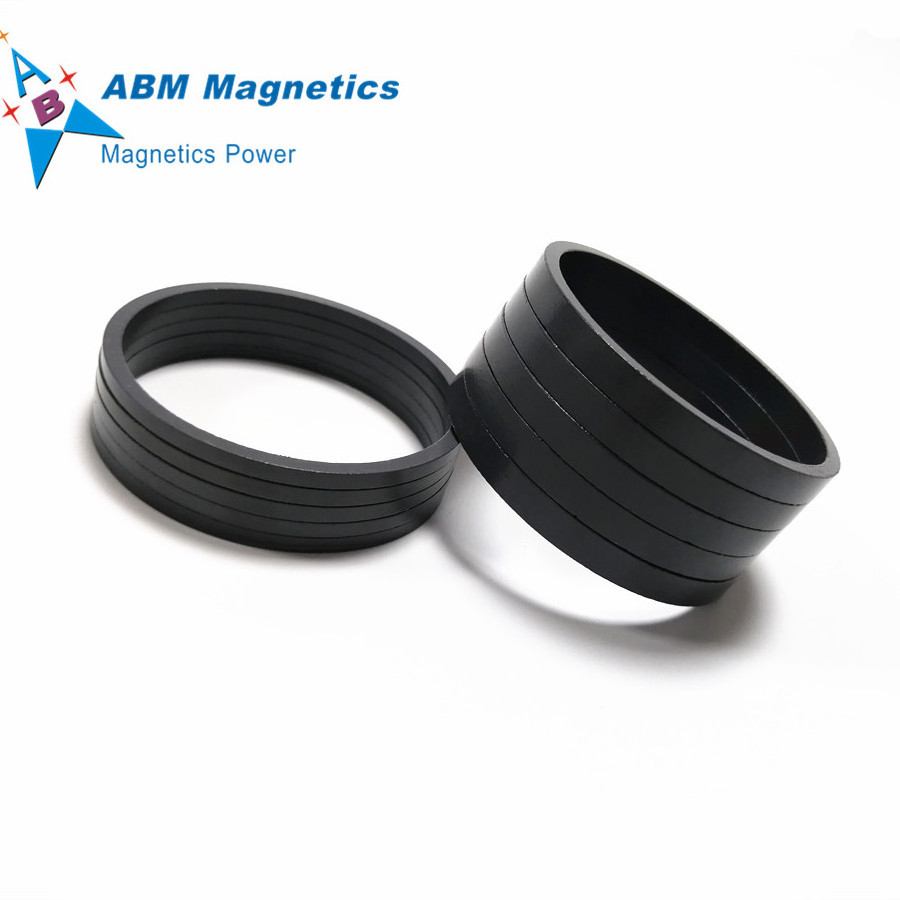

>> ABM can supply a variety of different size, shape and grade magnets to customer, such as magnet disc, magnet block, magnet ring, arc magnet, bread magnet, cup magnet, magnet ball, magnet bar, magnetic hook, pot magnet,cylindrical magnet.

>>ABM often attended many exhibitions which forcusing on the Motor, Electric Machinery & Magnetic Materials design and manufacturing. In the exposition scene, many customers are very interesting in our magnets, especially in our design and manufacturing capability.

ABM focus on providing best quality magnet to every customer and we also receive lots of 5 stars reviews from customer all over the world.