- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Allnatt

-

Delivery Time:

-

7 days

-

Material:

-

Neodymium Iron Boron Magnet

-

Size:

-

Customizable

-

Coating:

-

Ni-Cu-Ni

-

MOQ:

-

1000

-

Sample:

-

Avaliable

-

Lead time:

-

7-15 Days

-

Processing:

-

Sintered Permanent Neodymium Magnet

-

ODM/OEM:

-

Available

-

Certification:

-

CPST

Quick Details

-

Tolerance:

-

±1%

-

Grade:

-

Neodymium Magnet

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Allnatt

-

Delivery Time:

-

7 days

-

Material:

-

Neodymium Iron Boron Magnet

-

Size:

-

Customizable

-

Coating:

-

Ni-Cu-Ni

-

MOQ:

-

1000

-

Sample:

-

Avaliable

-

Lead time:

-

7-15 Days

-

Processing:

-

Sintered Permanent Neodymium Magnet

-

ODM/OEM:

-

Available

-

Certification:

-

CPST

Product Video

|

Material

|

Neodymium Iron Boron

|

|

|

Grade BH

|

Customizable from N28 to N54 (NM-EH )

|

|

|

Size

|

Customizable

|

|

|

Tolerance

|

+/- 0.05mm

|

|

|

Magnetism direction

|

Thickness, Axial(Customizable)

|

|

|

Lead Time

|

7-15 days

|

|

|

Sample

|

Available

|

|

|

Heartly welcome to contact us for the newest and most competitive price.

|

|

|

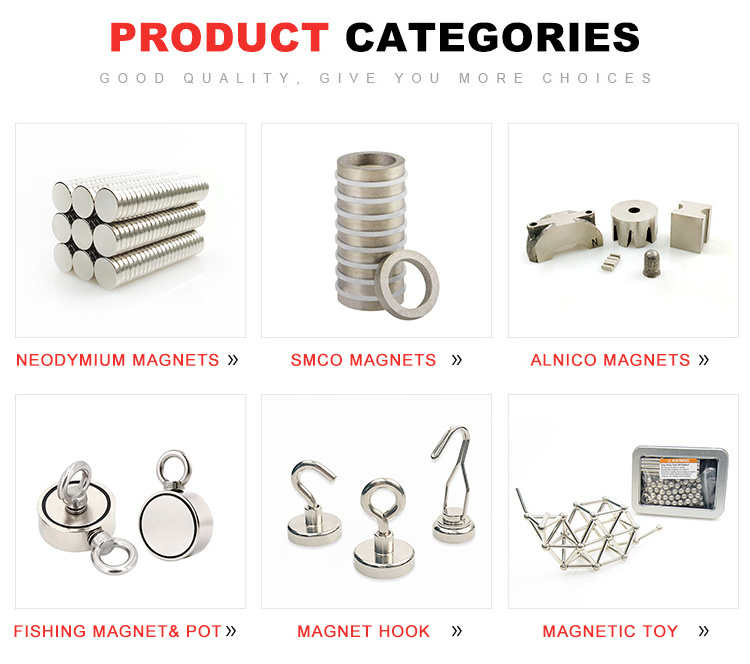

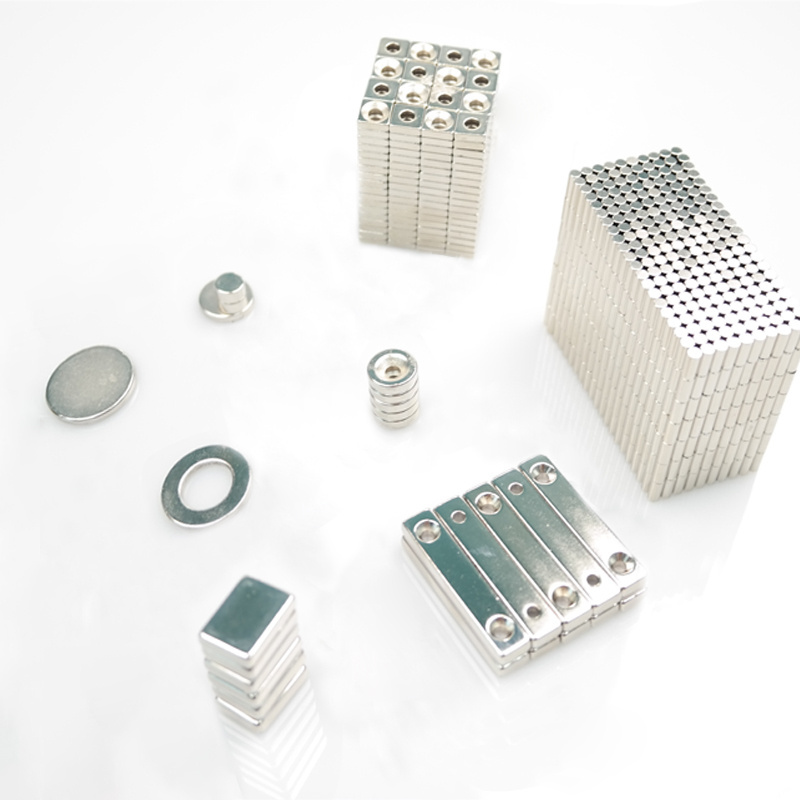

Round Magnet

Sintered Neodymium Iron Boron Magnets or "NdFeB" magnets provides the highest energy product of any material today and are

available in a wide range of shapes, sizes and grades.

available in a wide range of shapes, sizes and grades.

Block Magnet

Neodymium rectangular, block and cube magnets are powerful for their size, with an approximate pull strength of up to 300 lbs.

Block Magnet with Countersunk Hole

Allnatt International is a newly founded trading and manufacturing company offers one-step complete industrial chain from raw

material blank, cutting, electroplating and standard packing.

material blank, cutting, electroplating and standard packing.

Round Magnet with Countersunk Hole

We provide custom manufacturer neodymium magnets to your exact specifications, just send us your request and we'll help you

determine the most cost effective solution for your project.

determine the most cost effective solution for your project.

Sintered Nd-Fe-B Magnet Properties

Magnet Plating and Coating Options

The Above Chart is a list and description of common plating options for custom magnets. Why do magnets need to be plated?

❃ Oxidization (Rust)

Nd-Fe-B magnets will oxidize(rust) if left exposed in air. When a plating wears down or cracks, the exposed area will oxidize. An oxidized area will not result in complete degradation of the magnet, only the oxidized area will lose its strength. However the magnet will lose some structural integrity and become more susceptible to breakage.

❃ Durability

Depending on shape, permanent magnet substrate is brittle. A multilayered metal plating like nickel or zinc improves the magnets resistance to chipping and wear, particularly around corners.

❃ Harsh Environments

Plating vary in their tolerance of different harsh chemicals and abrasion. Salt and humidity in regions near the ocean are commonly overlooked when selecting a plating. Be sure to consider the magnets environment when selecting a plating. The most common type of plating for neodymium magnets Nickel (Ni-Cu-Ni) Intended for indoor use. It has proven to be very resilient when subjected to normal wear and tear. However it will corrode outdoors in prolonged exposure to salt water, salty air, or harsh chemicals.

Magnetization Direction

A

Magnetic field

is an invisible flux moving from one end of the magnet to the other. Shown in Figure1. The flux consists of moving or spinning electrically charged particles invisible to the eye. If the max working temperature meet the requirement, then the permanent magnets can retain the magnetic field for very long time nearly forever.

Magnets have

potential energy

which means that they have the ability to conserve energy. The magnet will display or release some of its conserved energy when pulling towards or attaching to something then conserve or store the energy that the user exerts when pulling it off. Every magnet has a north seeking and a south seeking face on opposite ends. The north face of one magnet will always be attracted towards the south face of another magnet.

Application Fields

Neodymium magnets

are strong magnets, normally used for many types of sectors, commercial, industrial & technical applications where

strong permanent magnets

are required. Due to their high-magnetic strength, components that previously had to be large and heavy can now be miniaturized by using Neodymium magnet material.

Common Applications

are holding systems requiring very high holding forces, sensors, reed switches, hard disc drives, audio equipment, acoustic pick-ups,headphones & loudspeakers, MRI scanners, magnetically coupled pumps · motors & generators, magnetic tool holders, magnetic bearings, door catches, dental instruments, medical devices, magnetic separators, lifting machinery, crafts & model making, hanging artwork, levitation devices,POP displays, commercial signage, packaging closures, jewelry clasps & more.

Our Factory

Allnatt International is a manufacturer and trading company of Nd-Fe-B permanent magnets.

Our products

include Nd-Fe-B finished and unfinished product. All magnet materials and coatings meet the standards of SGS and RoHS.

Our

associated

factory

makes high quality magnet to meet our customers' different requirements.

Our products

sell well in over 50 countries and regions all over the world such as America, the EU, the Middle East, Hong Kong, etc.

Our factory

has adopted the most advanced technology (thin strip alloy and hydrogen decrepitation).

Our associated factory have a professional R&D team. We can design and produce according to the drawings provided by our customers. ODM and OEM orders

are welcomed.

Hot Searches