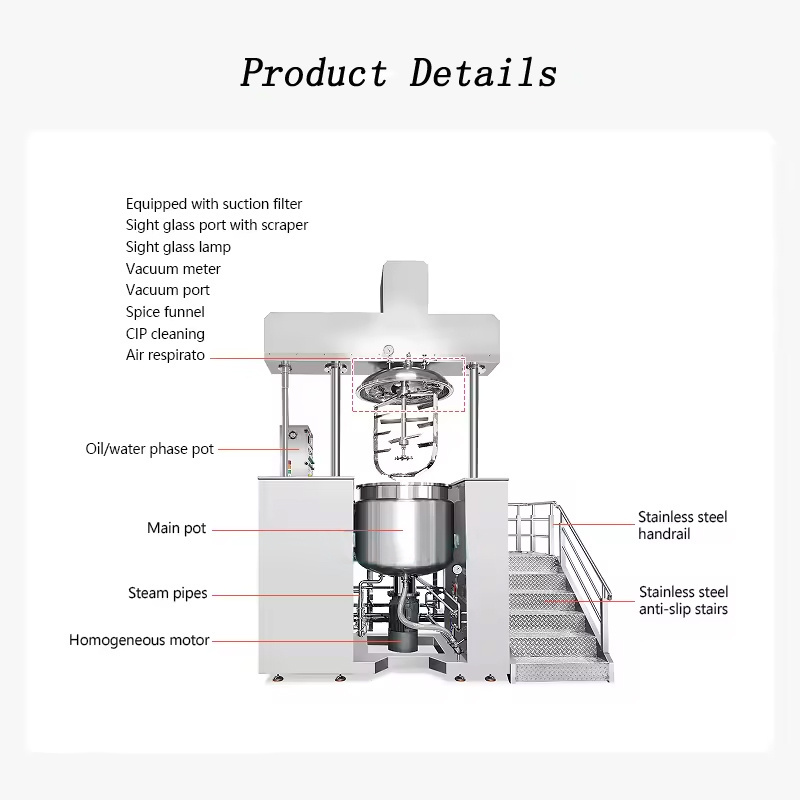

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

250 KG

-

Place of Origin:

-

China

-

Power (kW):

-

6 kW

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Mixing Tank

-

Function:

-

Homogenzing

-

Machine Type:

-

Industiral Blender Mixer Machine

-

Application scope:

-

Homogenizing Mixer Shearing

-

Heating method:

-

Electric Steam Heating

-

Stirrer type:

-

High Speed Homogenizer

-

Homogenizer:

-

0-3600rpm

-

Name:

-

Cosmetic Creams Mixing Tank

-

Mixing type:

-

Liquid Mixture Stirring

Quick Details

-

Barrel Volume (L):

-

500

-

Max. Loading Volume (L):

-

500 L

-

Range of Spindle Speed(r.p.m):

-

0 - 3600 r.p.m

-

Weight (KG):

-

250 KG

-

Place of Origin:

-

China

-

Power (kW):

-

6 kW

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Mixing Tank

-

Function:

-

Homogenzing

-

Machine Type:

-

Industiral Blender Mixer Machine

-

Application scope:

-

Homogenizing Mixer Shearing

-

Heating method:

-

Electric Steam Heating

-

Stirrer type:

-

High Speed Homogenizer

-

Homogenizer:

-

0-3600rpm

-

Name:

-

Cosmetic Creams Mixing Tank

-

Mixing type:

-

Liquid Mixture Stirring

Products Description

Cosmetic Vacuum Emulsifying Mixer Series Equipment

Product Details

* High speed vacuum emulsifying mixer homogenizer .might mixing and disperse viscously. Solid and liquid raw material can dissolve material which is hard to dissolve such as AES, AESA LSA during liquid production which can save energy consumption and shorten production the and shorten production period.

* Cream mixer mixing tank main adopts stepless timing device which reduce babble occur under low temperature and highviscosity condition less air bubble will be formed to produce liquid washing products.

* Finished products can be discharged by Disc-valve or suitable to all liquid wash products.

* Cream mixer mixing tank main adopts stepless timing device which reduce babble occur under low temperature and highviscosity condition less air bubble will be formed to produce liquid washing products.

* Finished products can be discharged by Disc-valve or suitable to all liquid wash products.

Composition Of Emulsifying Pot

RHJ vacuum crea mixer mixing tank is professionally designed according to the ointment manufacturing process of cosmetics andointments etc. products through introducing advanced technology from abroad. The cream mixing machine unit is composed of pre-treating boiler, vacuum emulsifying and blending boiler, vacuum pump, hydraulic system, dumping system, electric controlsystem and work platform etc. The machine unit is featured by simple operation, stable performance, good homogenizing performance, high production efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc.

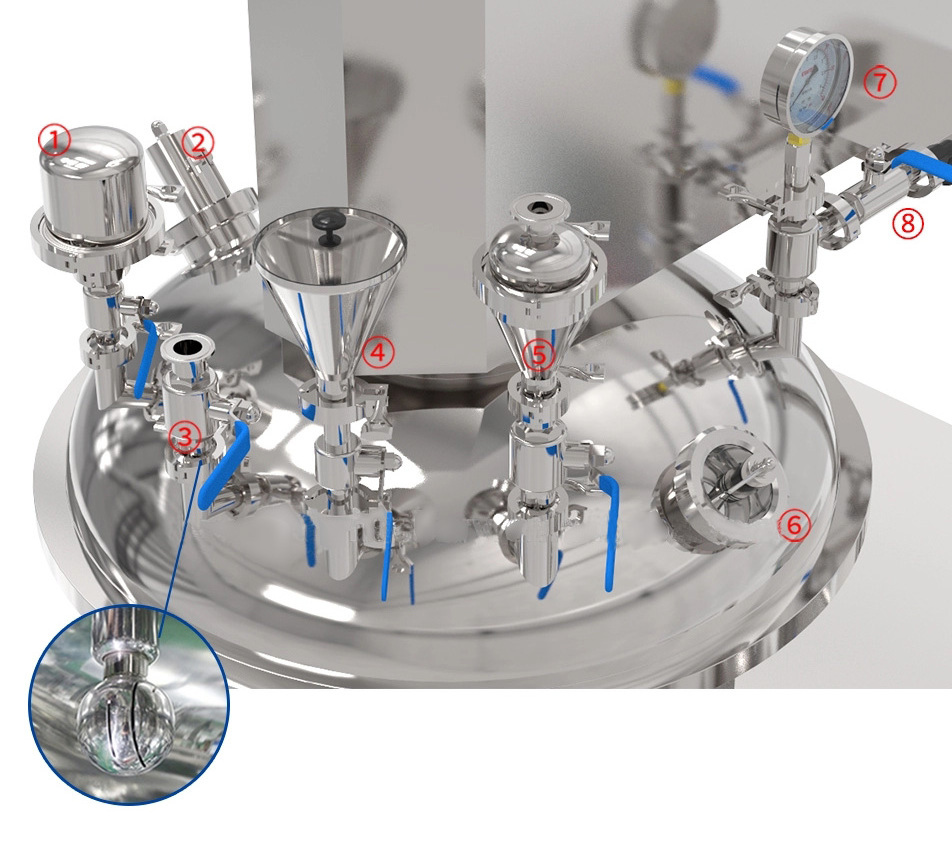

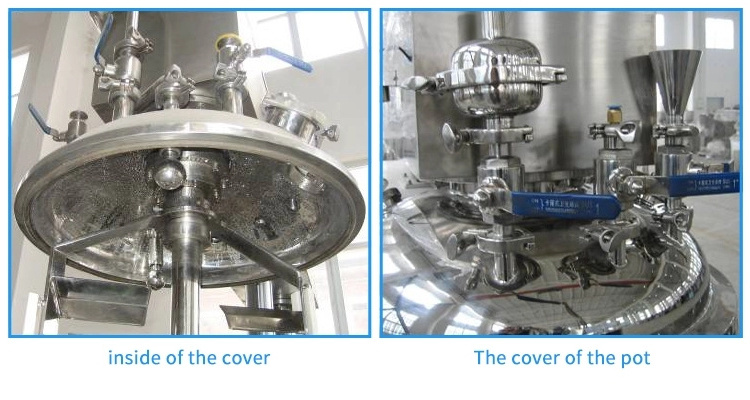

① Air filter ② Sight glass ③CIP spray ball ④ Fragrance hopper

⑤ Suction hopper ⑥Sight glass windom ⑦Vaccum gauge ⑧ Vaccum valve

(From oil &water pot

to main tank)

⑤ Suction hopper ⑥Sight glass windom ⑦Vaccum gauge ⑧ Vaccum valve

(From oil &water pot

to main tank)

Hot Searches