- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

2 x 5.5kw

-

Dimension(L*W*H):

-

3320x2425x2670mm, 3320x2125x2670 mm, 3320x2425x2670mm, 3320x2125x2670 mm

-

Weight:

-

2000 KG

-

Product Application:

-

Wash,fractionate and dehydrate

-

Capacity(t/h):

-

30-60t/h

-

Speed of Spiral:

-

3.6-12.5 r/min

-

Sand Return:

-

6-230 t/h

-

Spiral Diameter:

-

500-2000 mm

-

Overflow:

-

32-400 t/h

-

Product capacity:

-

30-60t/h

-

Feeding size:

-

≤10mm

-

Product name:

-

Gold Wash Machinery Mineral Gold Sand Submerged Spiral Separator

-

Certification:

-

ISO9001:2008,CE

Quick Details

-

Production Capacity:

-

30-60t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengchang

-

Voltage:

-

2 x 5.5kw

-

Dimension(L*W*H):

-

3320x2425x2670mm, 3320x2125x2670 mm, 3320x2425x2670mm, 3320x2125x2670 mm

-

Weight:

-

2000 KG

-

Product Application:

-

Wash,fractionate and dehydrate

-

Capacity(t/h):

-

30-60t/h

-

Speed of Spiral:

-

3.6-12.5 r/min

-

Sand Return:

-

6-230 t/h

-

Spiral Diameter:

-

500-2000 mm

-

Overflow:

-

32-400 t/h

-

Product capacity:

-

30-60t/h

-

Feeding size:

-

≤10mm

-

Product name:

-

Gold Wash Machinery Mineral Gold Sand Submerged Spiral Separator

-

Certification:

-

ISO9001:2008,CE

Gold Wash Machinery Mineral Gold Sand Submerged Spiral Separator Classifier Machine

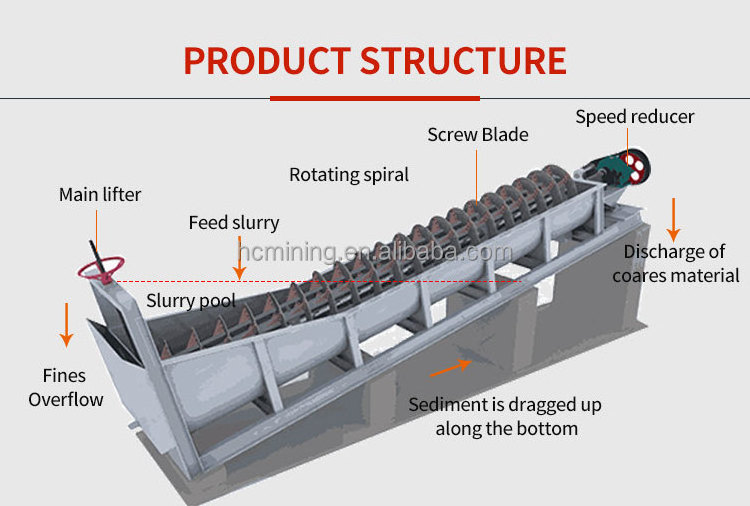

Spiral classifier is one of beneficiation equipment, based on user requirements, it can be divided into single and double spiral classifier. Depend on specific gravity of solid particles, so different sedimentation velocity in a liquid principle, spiral classifier is a mechanical grading equipment. Feed mill can grind the powder level in the filter, and then use the coarse material spiral piece rotary vane screwed mill feeder to filter out fine material discharged from the overflow tube.

According to the difference in sedimentation rate of mineral particles and mud, the particle sizes of ores with 1.5mm-0.03mm are classified. Waste mud or water for ore sand can be separated from the ores. It’s also usually applied to ore washing, desliming and dehydration and so on.

Advantage

1. Low power cosumption,high classifying efficiency

2. Heavy duty, long workinglife

3. Powerful manual control and electric control lifting device

4. Wide choice of weir height, rigid tank and substructure

1. Low power cosumption,high classifying efficiency

2. Heavy duty, long workinglife

3. Powerful manual control and electric control lifting device

4. Wide choice of weir height, rigid tank and substructure

spiral separator classifier

/

spiral sand wash machine

/

stone washer machine

Different solid granularities have different gravity and thus have different dropping speed. The fine ore granularities floating in the water will overflow and the big ones will sink to the bottom and discharge from the upper part by spiral pushing.

It can filter the granularities from the machine and then spin the rough particles to charging part by spiral vane and discharge the fine granularities from the overflow pipe. The base of the machine adopts a channel steel and the body adopts welded steel plate. The water inlet of spiral axle and axle head adopt pig iron cover for wear proofing and long life operation. The lifting equipment has two types, manual control and electric control.

Technical Parameter

|

Model

|

Spiral diameter(mm)

|

Speed of Spiral(r/min)

|

Power (kw)

|

|

Slope (°)

|

Power(KW)

|

|

|

|

|

|

Sand Return (t/h)

|

Overflow (t/h)

|

|

|

|

|

FG500

|

500

|

8-12.5

|

6-11

|

32

|

12-18

|

1.1

|

|

|

FG750

|

750

|

6-10

|

11-24

|

65

|

12-18

|

3

|

|

|

FG1000

|

1000

|

5-8

|

25-45

|

110

|

12-18

|

5.5

|

|

|

FG1200

|

1200

|

4-6

|

50-80

|

155

|

12-18

|

7.5

|

|

|

FG1500

|

1500

|

4-6

|

70-115

|

235

|

12-18

|

7.5

|

|

|

FG1800

|

1800

|

2.5-6

|

100-190

|

310

|

12-18

|

11

|

|

|

FG2000

|

2000

|

3.6-5.5

|

160-230

|

400

|

12-18

|

15

|

|

spiral separator classifier / spiral sand wash machine / stone washer machine

spiral separator classifier / spiral sand wash machine / stone washer machine

The spiral classifier tank is heavy plate with strong structural base. The extra heavy shaft has an improved submerged bearing.

The greatest improvements, however, are found in the drive-unit which has been strengthened and improved over all other classifiers.

A specially designed classifier reducer eliminates the “over – hang” or cantilevered load normally found where the reducer shaft carries the pinion. The Classifier Reducer has an outboard bearing integral with the reducer base which provides positive alignment of the bevel gears.

Hot Searches