- Product Details

- {{item.text}}

Quick Details

-

Suitable raw material:

-

NBR/Latex

-

Control system:

-

PLC+Touch Screen

-

Heating method:

-

Nature gas/coal/diesel ect

-

Speed:

-

controlled

-

Voltage:

-

380V,450V,ect

-

qualification rate:

-

99%

-

hand mould:

-

ceramic

-

Installation:

-

supply engineers for site installation

-

Machine size:

-

be adjustable

Quick Details

-

Production Capacity:

-

5000 pcs/hour

-

Place of Origin:

-

Shandong, China

-

Name:

-

Glove Making Machine Latex Dipping machine

-

Suitable raw material:

-

NBR/Latex

-

Control system:

-

PLC+Touch Screen

-

Heating method:

-

Nature gas/coal/diesel ect

-

Speed:

-

controlled

-

Voltage:

-

380V,450V,ect

-

qualification rate:

-

99%

-

hand mould:

-

ceramic

-

Installation:

-

supply engineers for site installation

-

Machine size:

-

be adjustable

2020 Nitrile Hand Glove Making Machine with good price

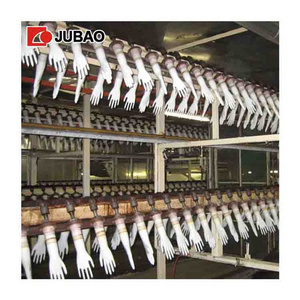

1,Adopt the most advanced gloves production technology and production process layout, product qualification rate is more than 98%, protein

content is lower than 120 micrograms per gram;

2,TPU Coating technology

3,Imported surfactant solidifier, finished membrane is uniform, no powder mold release

4,The introduction of foreign advanced transmission main chain structure, chain little resistance during operation, Production of high speed, stable operation

5,A main motor drag, solve the drag, difficult to synchronize, fault point, difficult maintenance, and other issues

6,Adopt vertical hot air circulation drying oven, compared with other forms of hot air circulation, save energy consumption by almost 20%

7,Used for cleaning mold splitter six roller long hair scrub mould technology;

8,Mold directional, machine printing technology;

9,A variety of specifications of production, on the same edge automatic adjustment, the PU edge roller, long service life;

10,Can design according to the needs of customers of different length, height, cost models;

Machine parts all be prepared at seller ’ s site,machine frame will be installed at customer ’ s site. After machine part and machine material arrive

to customer’s site,we will send 2~3 engineers and the buyer need to offer another 5-6 experienced mechanical workers to help the installation.

Machine testing also will be at customer's site. And seller supply install within 60 days, the buyer need to pay 200USD/day for each engineer.

The engineer ’ s tickets and accommodation is born by buyers.

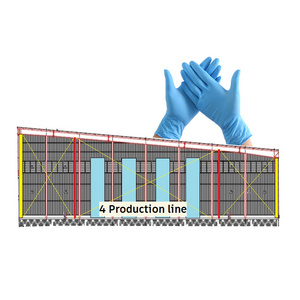

1 , Production line size :60m×1.8m×6.5m×6Layers

2 , Voltage: 34 kw/hr

3 , Capacity :6 000pcs/hr (3 000pairs/hr ) 144000 pca/day (72 000pairs/day )

4 , Heating method: natural gas heating.

| Mchine Size ( M ) | Speed (M/Min) | Capicity ( Pcs/Hr) | Power ( Kw/Hr ) | Chain ( M ) |

| 55M*1.8M*8M | 10 | 6000 | 34 | 360 |

| 70M*1.8M*8M | 10 | 7200 | 45 | 480 |

| 80M*1.8M*8M | 21.6 | 12000 | 70 | 600 |

| 110M*1.8M*13M*8layers*2 | 16.6 | 20000 | 120 | 640 |

| 110M*1.8M*16M*10layers*2 | 25 | 30000 | 190 | 1100 |