- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

pumpkin melon seeds harvester

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TAIZY

-

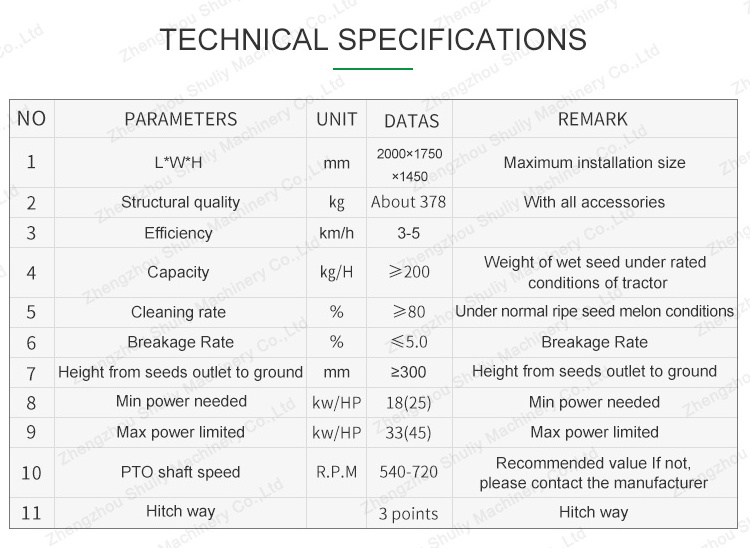

Dimension(L*W*H):

-

2000*1750*1450mm

-

Weight:

-

378 KG

-

Marketing Type:

-

New Product 2022

-

Name:

-

Pumpkin Seed Harvester

-

Model:

-

TZY500

-

Efficiency:

-

3-5km/h

-

Capacity:

-

≥200kg/H

-

Cleaning rate:

-

≥80%

-

Breakage Rate:

-

≤5.0%

-

Size:

-

2000x1750x1450mm

-

Min power needed:

-

18(25)kw/HP

-

Max power limited:

-

33(45)kw/HP

-

Structural quality:

-

About 378kg

Quick Details

-

Number of Rows:

-

1

-

Working Width(mm):

-

1500 mm

-

Tractor Power(HP):

-

25 - 45 HP

-

Usage:

-

pumpkin melon seeds harvester

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TAIZY

-

Dimension(L*W*H):

-

2000*1750*1450mm

-

Weight:

-

378 KG

-

Marketing Type:

-

New Product 2022

-

Name:

-

Pumpkin Seed Harvester

-

Model:

-

TZY500

-

Efficiency:

-

3-5km/h

-

Capacity:

-

≥200kg/H

-

Cleaning rate:

-

≥80%

-

Breakage Rate:

-

≤5.0%

-

Size:

-

2000x1750x1450mm

-

Min power needed:

-

18(25)kw/HP

-

Max power limited:

-

33(45)kw/HP

-

Structural quality:

-

About 378kg

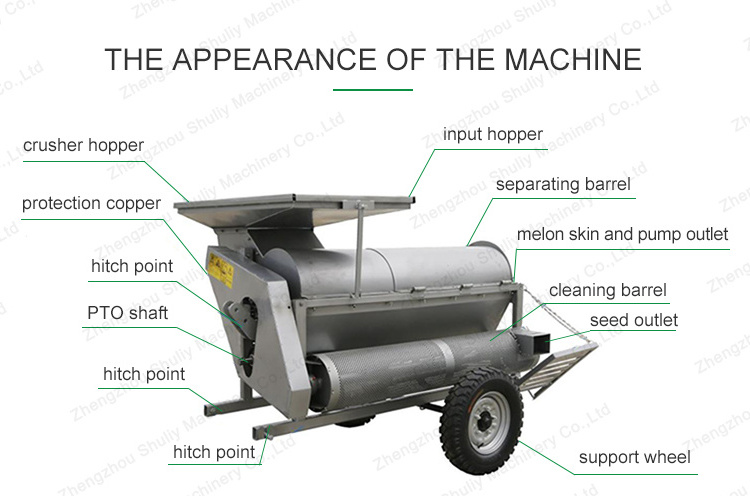

Pumpkin Seed Extractor is a compound work tool that can complete multiple operations such as crushing, squeezing, separation, and cleaning at one time. This machine is mainly used for harvesting and deseeding of pumpkins, watermelons and other melons.

The appearance of this product is fully configured, and the configuration and color of the purchased product are subject to the actual order. The drive shaft and supporting wheel are optional parts. Please note that different models are slightly different. The power input can be changed to electric motor, diesel engine, etc. according to user requirements.

Maintenance in use:

1. After the first 4 hours of work, check whether all bolts and nuts are tight;

2. For all rotating positions (such as bearings, sprockets, chains, etc.), oil or grease must be added every 4 hours;

3. Check every day whether there are weeds and vines entangled in the crushing box and separating barrel, and clean up if necessary;

4. Before long-distance transportation and after each shift, all threaded connections should be thoroughly inspected. If any tightening bolts are loose, they should be tightened immediately.

5. Check and add butter once every work shift.

6. Important: Check each work component for any deformation or damage. If any problem is found, it should be corrected, repaired or replaced in time.

7. Eliminate sand and debris on the machine every day to prevent early corrosion.