- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v, 220v/380v

-

Dimension(L*W*H):

-

690x980x2120 mm

-

Motor Power (kW):

-

3

-

Model Number:

-

JH21-25T

-

Weight (T):

-

2.45

-

Product name:

-

Punch Press Machine

-

Nominal Pressure:

-

250kn

-

Table Hole Diameter:

-

150 mm

-

Control system:

-

electric/hand

-

Material Processed:

-

steel/aluminum/metal

-

Size:

-

690x980x2120 mm

-

Power(W):

-

3000

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

CE

-

Nominal Force (kN):

-

250

Quick Details

-

Slide Stroke (mm):

-

80

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KINGBALL

-

Voltage:

-

220v/380v, 220v/380v

-

Dimension(L*W*H):

-

690x980x2120 mm

-

Motor Power (kW):

-

3

-

Model Number:

-

JH21-25T

-

Weight (T):

-

2.45

-

Product name:

-

Punch Press Machine

-

Nominal Pressure:

-

250kn

-

Table Hole Diameter:

-

150 mm

-

Control system:

-

electric/hand

-

Material Processed:

-

steel/aluminum/metal

-

Size:

-

690x980x2120 mm

-

Power(W):

-

3000

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

CE

-

Nominal Force (kN):

-

250

Product Description

mini press machine power press machine from KINGBALL

Detailed Images

Features:

1,Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability;

2,Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact;

3,The crankshaft undergoes gringding treatment after high frequency quenching;

4,Lengthened six-face rectangle guide with a surface of bronze plate;

5,Vertical located crankshaft, compact structure;

6,PLC control and imported safety duplex valve;

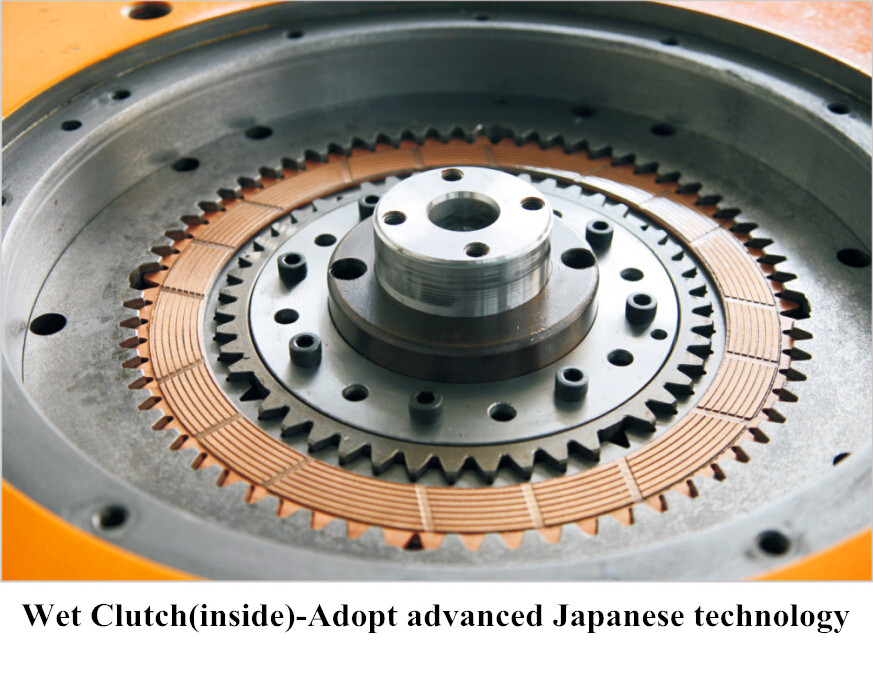

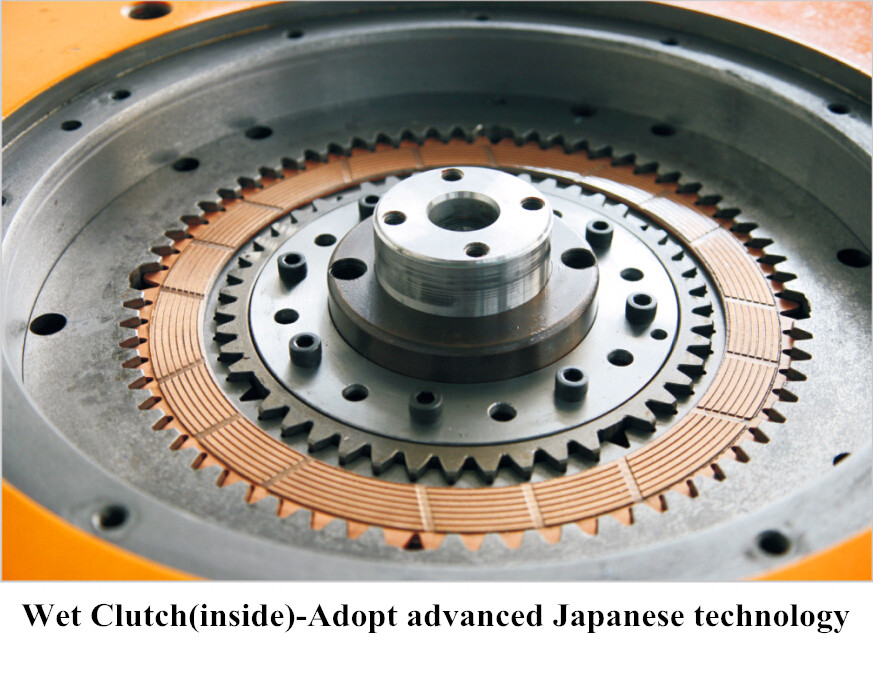

7,Wet type combined multi discs friction clutch and brake;

8,Hydraulic onerload protected.

Details:

1,The JH21 C-frame single crank press is suitable to process the lightweight and thin materials through blanking, piercing,

bending, forming, interlink with ROT line or transfer unit. Suitable for single and progressive die application, and it owns the

capacity ranging from 25 ton to 400 ton

2,The press use high torque and low noise wet clutch and brake.

3,The steel welded body ensures rigid frame with less deflection. High accuracy transmission gears and high rigidity crank ensure

press long life and accuracy. Forced lubrication system with default monitor ensures the operation reliability.

4,User-friendly design and all-function electric control system enable the accessories to attach easily.

1,Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability;

2,Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact;

3,The crankshaft undergoes gringding treatment after high frequency quenching;

4,Lengthened six-face rectangle guide with a surface of bronze plate;

5,Vertical located crankshaft, compact structure;

6,PLC control and imported safety duplex valve;

7,Wet type combined multi discs friction clutch and brake;

8,Hydraulic onerload protected.

Details:

1,The JH21 C-frame single crank press is suitable to process the lightweight and thin materials through blanking, piercing,

bending, forming, interlink with ROT line or transfer unit. Suitable for single and progressive die application, and it owns the

capacity ranging from 25 ton to 400 ton

2,The press use high torque and low noise wet clutch and brake.

3,The steel welded body ensures rigid frame with less deflection. High accuracy transmission gears and high rigidity crank ensure

press long life and accuracy. Forced lubrication system with default monitor ensures the operation reliability.

4,User-friendly design and all-function electric control system enable the accessories to attach easily.

Technical Parameters

|

Parameter

|

|

Unit

|

JH21-25

|

JH21-45

|

JH21-60

|

JH21-80

|

JH21-100

|

|

|

Nominal Capacity

|

|

KN

|

250

|

450

|

600

|

800

|

1000

|

|

|

Nominal Stroke

|

|

mm

|

3

|

4

|

4

|

5

|

5

|

|

|

Slide Stroke Length

|

|

mm

|

80

|

120

|

140

|

160

|

160

|

|

|

Slide Stroke

|

Fixed

|

times/min

|

100

|

80

|

70

|

60

|

55

|

|

|

|

Variable

|

times/min

|

60-100

|

50-80

|

45-70

|

40-60

|

40-70

|

|

|

Max. Die Set Height

|

|

mm

|

250

|

270

|

300

|

320

|

335

|

|

|

Die Height Adjustment

|

|

mm

|

50

|

60

|

70

|

80

|

90

|

|

|

Throat Depth

|

|

mm

|

210

|

225

|

270

|

310

|

330

|

|

|

Distance Between Uprights

|

|

mm

|

450

|

515

|

560

|

610

|

670

|

|

|

Slide Bottom Size

|

L x R

|

mm

|

360

|

410

|

480

|

540

|

620

|

|

|

|

F x B

|

mm

|

250

|

340

|

400

|

460

|

520

|

|

|

Handle Hole Size

|

Dia

|

mm

|

40

|

50

|

50

|

50

|

70

|

|

|

|

Depth

|

mm

|

65

|

60

|

70

|

65

|

90

|

|

|

Bolster Size

|

L x R

|

mm

|

720

|

825

|

930

|

950

|

1060

|

|

|

|

F x B

|

mm

|

400

|

440

|

520

|

600

|

640

|

|

|

Bolster Thickness

|

|

mm

|

80

|

110

|

130

|

140

|

145

|

|

|

Table Hole Diameter

|

|

mm

|

150

|

150

|

150

|

180

|

180

|

|

|

Bolster Surface Height

|

|

mm

|

780

|

800

|

900

|

900

|

900

|

|

|

Overall Size

|

F x B

|

mm

|

1496

|

1585

|

1540

|

1765

|

2000

|

|

|

|

L x R

|

mm

|

945

|

1075

|

1200

|

1200

|

1300

|

|

|

|

H

|

mm

|

2120

|

2391

|

2570

|

2725

|

3010

|

|

|

Distance between foundation bolts

|

F x B

|

mm

|

980

|

1075

|

1100

|

1210

|

1365

|

|

|

|

L x R

|

mm

|

690

|

760

|

840

|

920

|

1020

|

|

|

Motor Power

|

|

Kw

|

3

|

5.5

|

5.5

|

7.5

|

7.5

|

|

|

Weight

|

|

Kg

|

2450

|

3550

|

5150

|

6450

|

8650

|

|

Optional Configuration

|

Standard Equipments:

|

|

Optional Equipments:

|

|

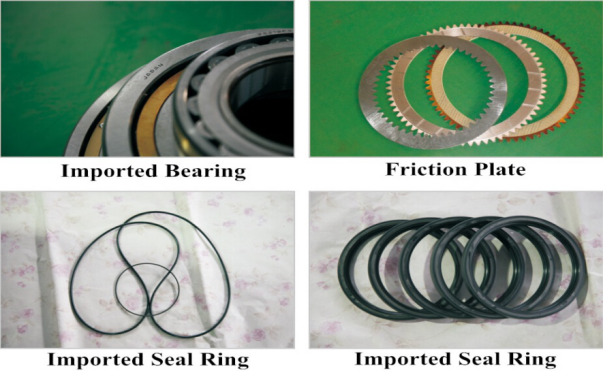

1) High Performance Wet clutch (Adopt advanced Japanese technology)

|

|

1) Light curtain

|

|

2) PLC

|

|

2) Foot pedal

|

|

3) Hydraulic overload protecting pump

|

|

3) Die cushion

|

|

4) Touch screen

|

|

4) Inverter

|

|

5) Cam controller

|

|

5) Variable speed motor

|

|

6) Die height adjusted motor (JH21-60 and upon models)

|

|

6) Auto feed shaft

|

|

7) Auto lubrication system

|

|

7) Die quick change device

|

|

8) Manual lubrication system

|

|

|

|

9) Double hand control panel

|

|

|

|

10) Electronic crankshaft angle indicator

|

|

|

|

11) Predetermined counter

|

|

|

|

12) Balance cylinders for slide and upper die

|

|

|

|

13) Work light

|

|

|

|

14) Joint for air

|

|

|

|

15) Joint for miss-feeding

|

|

|

|

16) Absorbing pads

|

|

|

Our Certifications

Our Customers

Our Factory&Company

Related Products

press brake nc machine

4-column hydraulic press machine

shearing machine

Hot Searches