- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/400V/415V

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

500 kg

-

Name:

-

cattle feed pellet machine

-

Application:

-

Poultry Farm

-

Capacity:

-

80-800KG/h

-

Usage:

-

Homemade pellet mill plan

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

Color:

-

Clients' Requirement

-

Function:

-

pellet making

-

Material:

-

Alloy Steel

-

Motor:

-

Chinese Brand

-

countries:

-

South Africa, UK, US, Europe

Quick Details

-

Max. Capacity:

-

500 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

AOLS

-

Voltage:

-

380V/400V/415V

-

Dimension(L*W*H):

-

5500*2200*2100MM

-

Weight:

-

500 kg

-

Name:

-

cattle feed pellet machine

-

Application:

-

Poultry Farm

-

Capacity:

-

80-800KG/h

-

Usage:

-

Homemade pellet mill plan

-

raw materail:

-

Sawdust, leaves, rice Husk, wood

-

Color:

-

Clients' Requirement

-

Function:

-

pellet making

-

Material:

-

Alloy Steel

-

Motor:

-

Chinese Brand

-

countries:

-

South Africa, UK, US, Europe

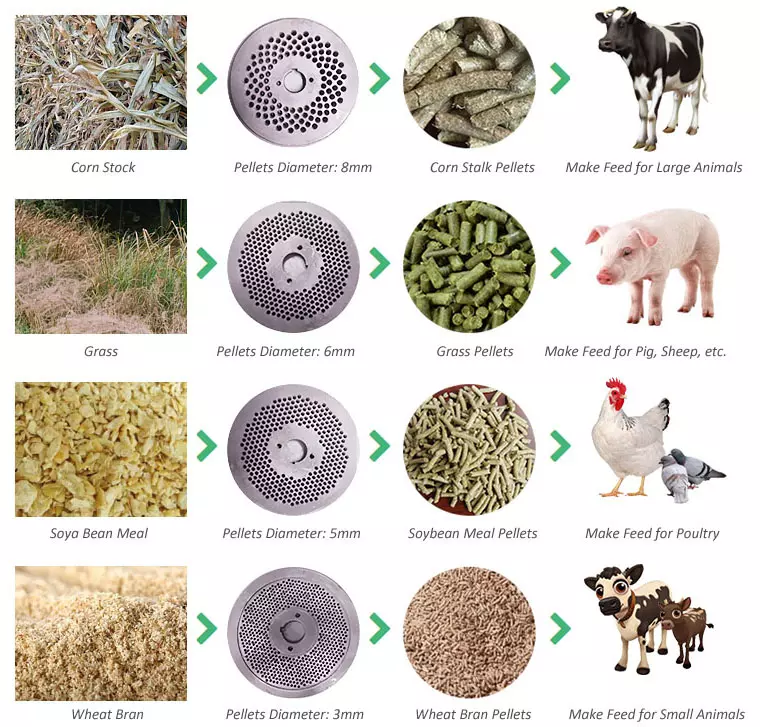

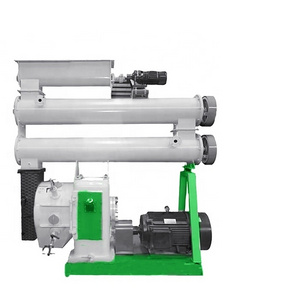

Home breeding sheep straw feed pellet machine silage pellet machine

This factory price sales of small feed pellet machine is suitable for medium and small scale farming households processing various livestock and aquatic feeds, it can reduce production cost. It can be used for raise rabbit, chicken, duck, goose, fish, pig, aquatic products, etc

Advantage:

1.Widely choice on different kind of biomass materials.

2.Pellet in different diameter can customized.

3.animal feed press machine Can equipped with Mixer ,conveyor into production line.

4.Can working in group,improve the working efficient.

5.Different Model to meed client own request.

6.Forage pellet machine Customized designs for customers .

7.Offer Turn-key service on Pellet Production Project.

|

Model |

KL-150 |

KL-200 |

KL-260 |

KL-300 |

KL360 |

KL-400 |

|

Power |

4KW/8HP |

7.5KW/15HP |

15KW/28HP |

22KW/35HP |

22KW/35HP |

22KW/55HP |

|

Output Sawdust |

60-90kg/h |

110-150kg/h |

220-280kg/h |

300-350kg/h |

400-450kg/h |

500-600kg/h |

|

Output Feed |

150-220kg/h |

200-300kg/h |

400-600kg/h |

600-800kg/h |

900-1000kg/h |

1.2-1.5t/h |

|

Dimension |

77*34*68cm |

100*43*95cm |

120*50*103cm |

132*53*107cm |

160*68*145cm |

160*68*145cm |

|

N.W (kg) |

95KG |

190KG |

330KG |

430KG |

600KG |

750KG |

|

G.W(kg) |

115KG |

210KG |

360KG |

470KG |

620KG |

780KG |

|

Humidity % |

10-15% |

10-15% |

10-15% |

10-15% |

10-15% |

110-15% |

|

raw materail |

3-5mm |

3-5mm |

3-5mm |

3-5mm |

3-5mm |

3-5mm |

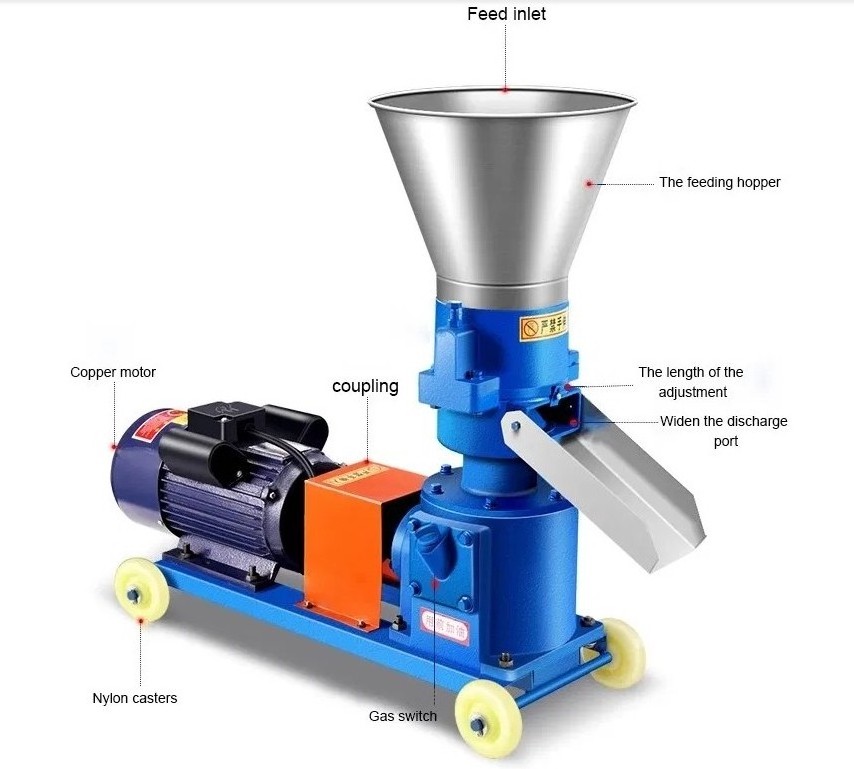

- Characteristic:

1. Powered by both diesel engine ,gasoline and motor,PTO driven

2. Direct Connection of motor shaft and belt drive

3. Pellet mill Machine Can run smoothly with few noises.

4. Pellet Machine can equipped wheel,move around

5. Machine can be used for making feed pellet,also make wood pellets

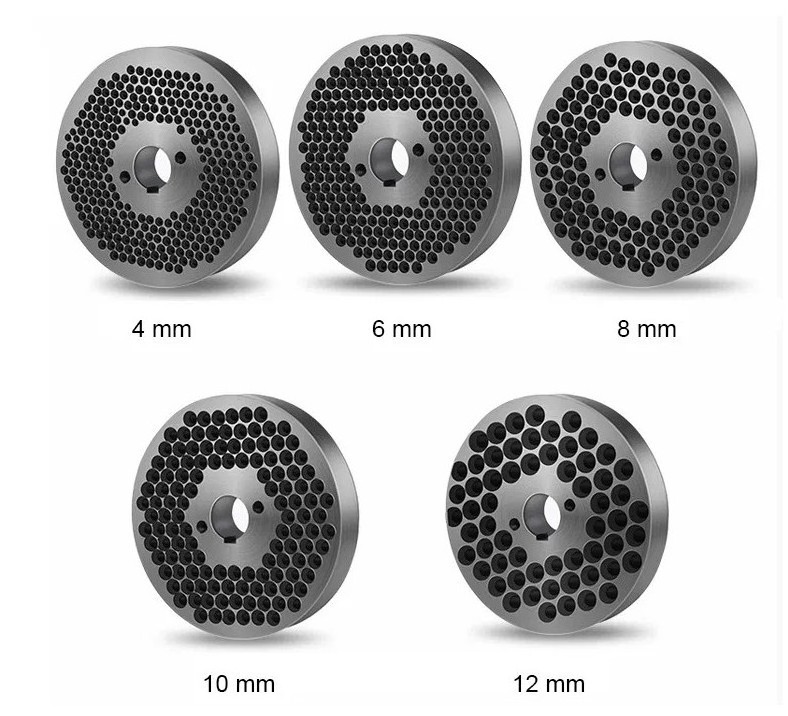

- Pellet Die Size

Our Pellet mill feed pelletizer machine have 2.5mm,3mm,4mm,5mm,6mm,8mm,10mm,12mm mould for your choice.

The 6mm and 8mm are the most common size. very suitable for making wood fuel pellets.

2.5mm and 3mm are very suitable for making animal feeds.Advantages of

our machines' output pellets is high density, high fuel value, low moisture and low ash content.

-

The Roller

The roller is machined with alloy steel.The material is gelatinized between the roll and the template with high temperature and discharged from the die hole under the roll.

-

The Die

Flat die adopt high quality wear-resisting alloy steel, which are processed by special heat treatment, high hardness, long working life.

Performance Features

- Transmission gears made of High quality alloy steel,surface adopts carburizing and quenching treatment,precision machining by grinding,smooth transmission,low noise,large carrying capacity,low temperature rise,long life etc.

- Spindle with a heavy thrust bearing,support axial force,long life span.

- Roller and flat die wear peace deal,both side can use the flat die ,long service life.

- Pellet machine uses large diameter roller,big yield,pelletizing rate is high,uniform high strength pellets.

- All bearings are sealed structure that effectively prevent dust,improve the working bearings,environment,extending bearing lift..

- Highest grade tool steel die and rollers that are designed to fit YOUR PRODUCT.

- Full consultation at NO Charge at YOUR FACILITY.

- Low wear of roller,dies and bearings.

- Do not need to add binder.

- Pellet diameter from 2.5-12mm for user select.

- Easier to clean than pellet machine with ring die.

- Small and lightweight,available for homemade or farm pellet production.

- If you need support on selection of Pellet Machine,contact us.

Attentions Of Operation

1. The operators should read the instructions carefully and have good understanding of the character of the Flat Die Pellet Mill, structure and application method. Stall and debug, use and maintain the pellet mill according to regulations.

2. Before connect the power supply, examine the ground cable is fine or not at first. Connect to the power of the machine and start the pellet mill are serious prohibited before connected the ground cable

3. Don’t inspect or replace the spare parts with the live cables, or the operators can get a shock or injured.

4. Be sure to stop the pellet mill when the service man maintain the pellet mill, and cut off all the electricity supply and hang on the warning sign, to prevent human error accident from unexpected operation of machine.

5. Special lubricant should be added into the bearing of compression rollers of the pellet mill after every 12 hours of the operation of the pellet mill.

6. Please do cut off the electricity when rotating the compression rollers by hand. Please do not touch the rotating compression rollers and flat die by hand or other objects.

7. The clearance between the compression rollers and the flat die should below 10.mm, too small the clearance give rise to over wear resistance between compression rollers and flat die, even the damage of the whole pellet mill.

8. When the temperature of the Flat Die Pellet Mill is below 10℃, the lubricant of the pellet mill are easy to freeze. Please warm the Flat Die Pellet Mill to 10℃ and start the machine.

Package

1.Machines will be packed in standard and quantities boxes ,the production will have a safe and complete journey from our factory to your place.

2.Packaging details standard export wooden case or in container.

Shipping

1,We will serve your shipping method about ocean transport ,air lift ,freights and so on.

2,The delivery time is usually 7-15 working days upon receipt of your payment.

If you are looking for alfalfa Pellet machine, or want build your own pellet plant , tell us below request:

- What’s your raw material is ?

- Raw material size mm,

- Moisture content %

- Final pellet diameter mm

- Output capacity kg/h ?

Upon we get your exactly request, we propose our offer in short time.