- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.02%

-

CrO Content (%):

-

0.1%~0.3%

-

SiC Content (%):

-

1.2%~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK32,SK35,DN12,DN14

-

Brand Name:

-

JUCOS

-

Product name:

-

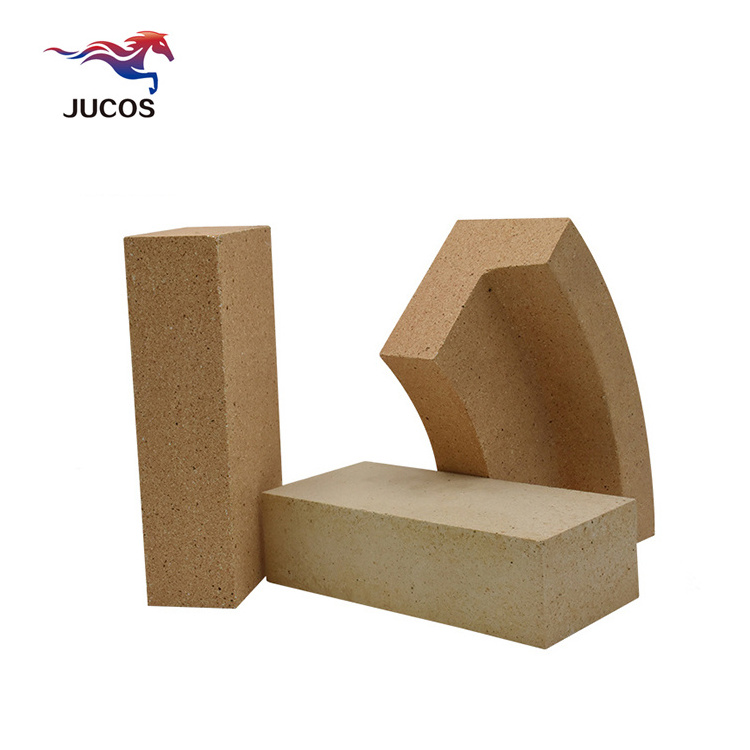

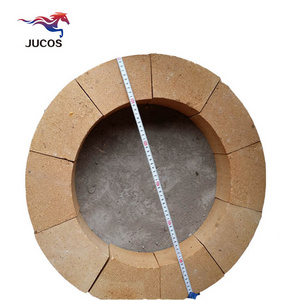

Refractory Sk34 Fire Clay Bricks For Pizza Oven

-

Color:

-

Yellow

-

Size:

-

Customizable

-

Bulk Density:

-

2.20g/cm3

-

Apparent porosity:

-

24%

-

Certifiacte:

-

ISO9001, CE, etc

-

Fe2O3:

-

≤2.0%

-

Cold crushing strength:

-

≥35MPa

-

Thermal linear expansion:

-

0.6%

-

Applications:

-

Nonferrous Metal Furnace

Quick Details

-

SiO2 Content (%):

-

55%

-

Al2O3 Content (%):

-

38%

-

MgO Content (%):

-

0.8~1.2%

-

CaO Content (%):

-

0.02%

-

CrO Content (%):

-

0.1%~0.3%

-

SiC Content (%):

-

1.2%~1.4%

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK32,SK35,DN12,DN14

-

Brand Name:

-

JUCOS

-

Product name:

-

Refractory Sk34 Fire Clay Bricks For Pizza Oven

-

Color:

-

Yellow

-

Size:

-

Customizable

-

Bulk Density:

-

2.20g/cm3

-

Apparent porosity:

-

24%

-

Certifiacte:

-

ISO9001, CE, etc

-

Fe2O3:

-

≤2.0%

-

Cold crushing strength:

-

≥35MPa

-

Thermal linear expansion:

-

0.6%

-

Applications:

-

Nonferrous Metal Furnace

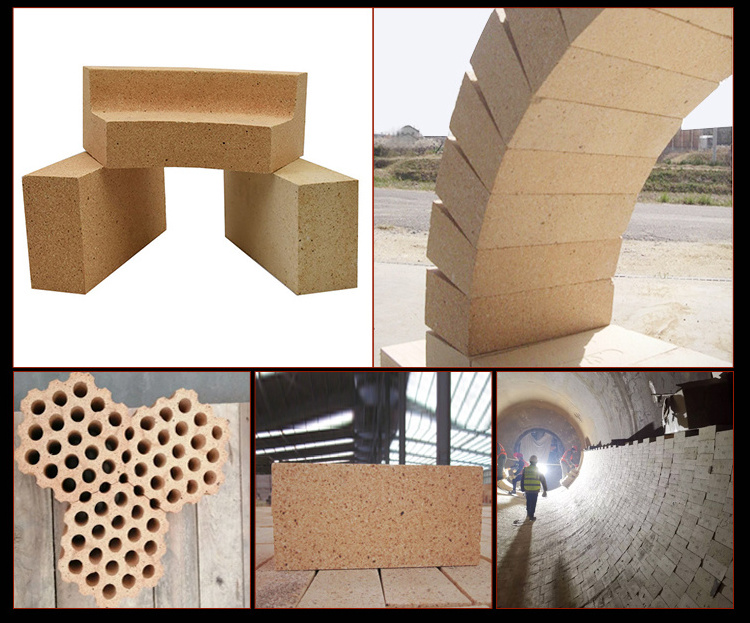

Descriptions Of Fire Clay Brick

Alumina contents range from 35% to 45%

Widely used throughout metallurgical industry

Widely used throughout metallurgical industry

Hard Fireclay bricks are alumina silicate bricks with the refractoriness of SK 32-34 and contain 35- 45% alumina. The bricks are made from various raw materials of fire clay, calcined chamotte, mullite etc . they are highly resistant to abrasion, spalling and corrosion. Because the bricks have low porosity, high strength, good resistance to thermal spalling and to abrasion and to creep, Jucos fireclay brick are applied for the linings of Coke Ovens, Glass furnace, Cement Rotary Kilns, Lime Kilns,Various Incinerators, Reheating Furnaces etc..

Features

1.Excellent resistance in slag abrasion

2.Lower impurity content

3.Good cold crush strength

4.Lower thermal line expansion in high temp

5.Good thermal shock resistance performance

6.Good performance in high temp refractoriness under load

Application

1.Reheating Furnace, Blast furnace

2.General Industrial Furnace etc, Coke Oven

3.Topedo Car, Cement Rotary klin

4.Various Rotary kiln, Chemical Reactor

5. Incinerator, Non Ferreous

6.MetalFurnace, Glass furnace

Features

1.Excellent resistance in slag abrasion

2.Lower impurity content

3.Good cold crush strength

4.Lower thermal line expansion in high temp

5.Good thermal shock resistance performance

6.Good performance in high temp refractoriness under load

Application

1.Reheating Furnace, Blast furnace

2.General Industrial Furnace etc, Coke Oven

3.Topedo Car, Cement Rotary klin

4.Various Rotary kiln, Chemical Reactor

5. Incinerator, Non Ferreous

6.MetalFurnace, Glass furnace

Physical And Chemical Indicators Of Product

|

Brand

Properties |

|

DN-12

|

DN-14

|

DN-17

|

SK-34

|

SK-33

|

SK-32

|

||||||

|

Refractoriness (SK)

|

|

35

|

34

|

34

|

34

|

33

|

32

|

||||||

|

Apparent Porosity (%)

|

|

12

|

14

|

17

|

23

|

24

|

26

|

||||||

|

Bulk Density (g/cm3)

|

|

2.40

|

2.34

|

2.25

|

2.20

|

2.15

|

2.00

|

||||||

|

Cold Crushing Strength (MPa)

|

|

70

|

65

|

50

|

35

|

30

|

20

|

||||||

|

Thermal Linear Expansion(%) @ 1,000℃

|

|

0.5

|

0.6

|

0.6

|

0.6

|

0.6

|

0.6

|

||||||

|

Permanent Linear Change (%)

@ 1,400℃ x 2hrs |

|

±0.1

|

±0.2

|

±0.2

|

±0.3

|

±0.5

|

±0.5

|

||||||

|

Refractoriness under Load (℃) @0.2MPa

|

|

1,500

|

1,470

|

1,430

|

1,350

|

1,300

|

1,250

|

||||||

|

Chemical

Composition (%) |

Al2O3

|

45

|

45

|

42

|

40

|

38

|

35

|

||||||

|

|

Fe2O3

|

1.3

|

1.5

|

1.7

|

2.0

|

2.2

|

3.0

|

||||||

|

Main Applications

|

|

- Reheating Furnace

- Blast furnace -Coke Oven,Torpedo Car, -Cement Rotary kiln, Various Rotary kiln, -Chemical Reactor, incinerator, Non Ferrous, metal Furnace, -Glass furnace -General Industrial Furnace etc. |

|

|

|

|

|

||||||

Hot Searches