- Product Details

- {{item.text}}

Quick Details

-

Insulation Material:

-

teflon

-

Place of Origin:

-

Jiangsu, China

-

wires:

-

0.02mm-10mm

-

Temperature range:

-

-40 - 1300degree

-

Thermocouple wire Type:

-

K/E/J/T/R/S/B

-

thermocouple wire surface treatment:

-

bright annealing, oxidizing

-

Surface Treatment:

-

hydrogen annealing

-

Resistance tolerance:

-

±3%

-

thermocouple wire feather:

-

soft wire or hard wire

-

Certificate:

-

ISO 9001 RoHS SGS

-

thermocouple grade:

-

I grade, or II grade

-

thermocouple wire EMF values:

-

inspection report supplied

Quick Details

-

Application:

-

measurement, thermocouple

-

Conductor Material:

-

Chrome / Alumel

-

Conductor Type:

-

single wire or stranded

-

Insulation Material:

-

teflon

-

Place of Origin:

-

Jiangsu, China

-

wires:

-

0.02mm-10mm

-

Temperature range:

-

-40 - 1300degree

-

Thermocouple wire Type:

-

K/E/J/T/R/S/B

-

thermocouple wire surface treatment:

-

bright annealing, oxidizing

-

Surface Treatment:

-

hydrogen annealing

-

Resistance tolerance:

-

±3%

-

thermocouple wire feather:

-

soft wire or hard wire

-

Certificate:

-

ISO 9001 RoHS SGS

-

thermocouple grade:

-

I grade, or II grade

-

thermocouple wire EMF values:

-

inspection report supplied

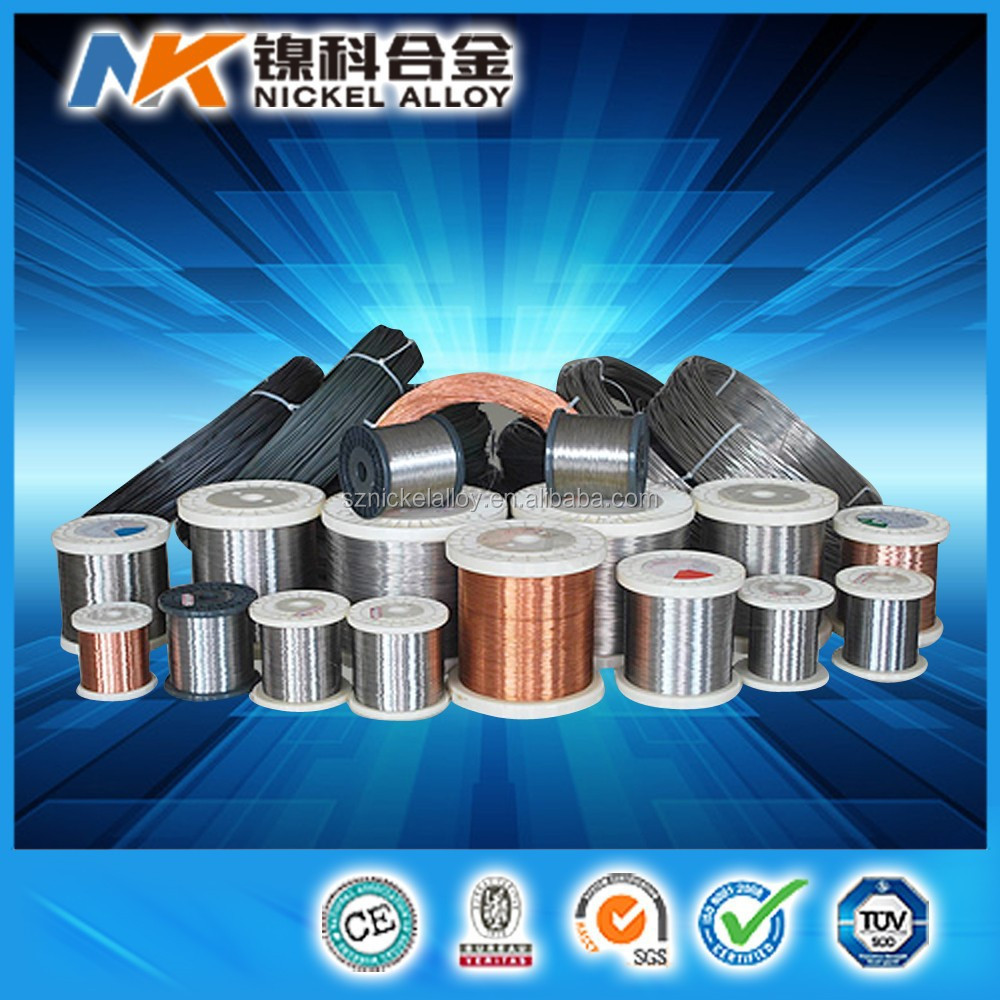

k type thermocouple wire

1. Stable EMF value

2. Precious test result

3 . IEC584-1 IEC584-2 standard

4 . EN 10204-3.1 certificate

China high temperature Chromel Alumel k type thermocouple wire

Thermocouple wire (Type K, N, E, J, T, S, B, R)

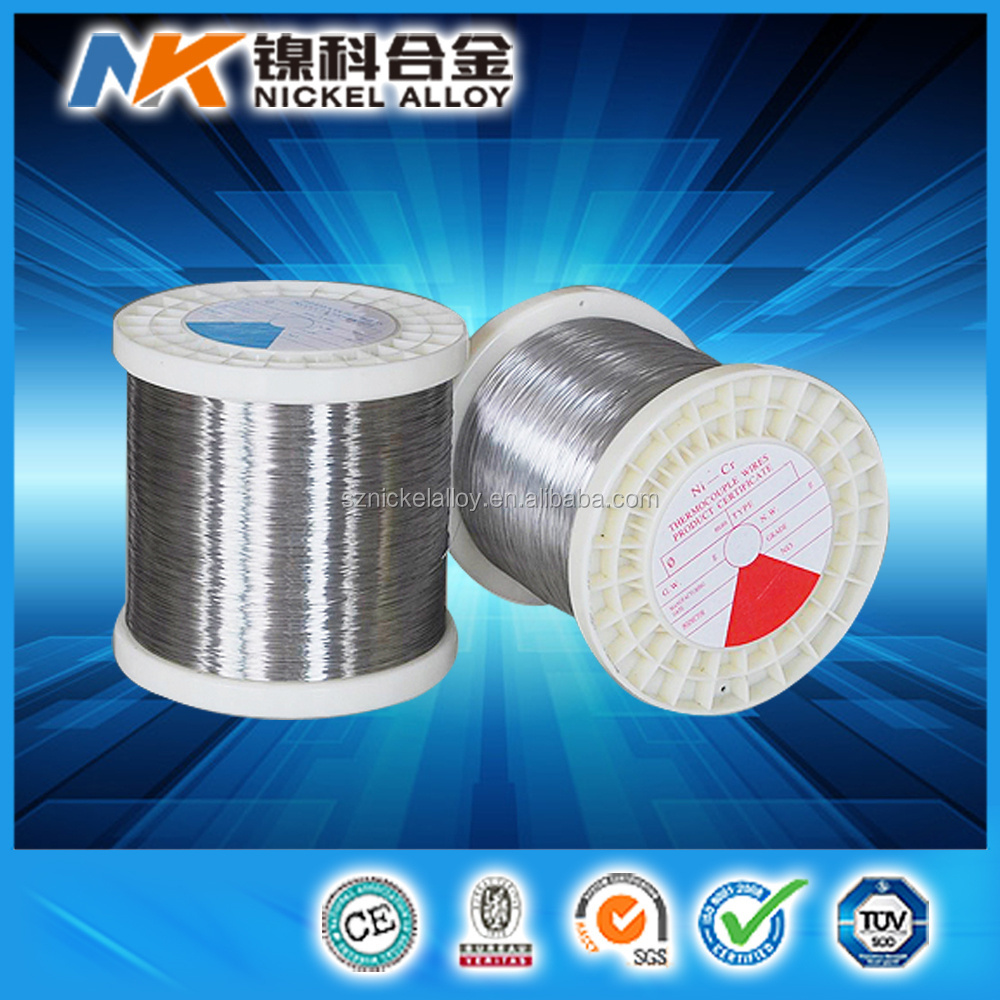

Type K (Chromel / Alumel)

Type K is the ‘general purpose’ thermocouple. It is low cost and, owing to its popularity, it is available in a wide varietyof probes. Thermocouples are available in the -200 °C to +1200 °C range. Sensitivity is approx 41 µV/°C. Use type K unless you have a good reason not to.

standards

We manufactures Type N, K, E, J and T in Thermocouple and Extension grades to Class 1 and 2 calibrations. Wires are manufactured to the appropriate part of BS EN 60584 - IEC 584. and to ANSI MC96. 1:1982. We can also comply with other standards and full calibration and EMF testing is performed at SGS laboratory with Certificates of Conformity supplied upon request.

Specifications

|

ISA |

Material

|

Temperature

Range°C

|

Sensitivity@

|

Error* |

App.** |

|

E |

Chromel & Constantan

|

-270~1000

|

60.9

|

LT:±1.67°C(±3°F)

|

I,O |

|

J |

Iron & Constantan

|

-210~1200

|

51.7

|

LT:±2.2~1.1°C(±4~2°F)

|

I,O,R,V |

|

K |

Chromel & Alumel

|

-270~1350

|

40.6

|

LT:±2.2~1.1°C(±4~2°F)

|

I,O |

|

T |

Copper & Constantan

|

-270~400

|

40.6

|

LT:±1~2%

|

I,O,R,V |

|

R |

Platinum & 87% Platinum/

13% Rhodium

|

-50~1750

|

6

|

LT:±2.8°C(±5°F)

|

I,O |

|

S |

Platinum & 90% Platinum/

10% Rhodium

|

-50~1750

|

6

|

LT:±2.8°C(±5°F)

|

I,O |

|

B |

70% Platinum/ 30% Rhodium & 94% Platinum/ 6% Rhodium (Pt-Rh & Pt-Rh) |

-50~1750

|

6

|

LT:±2.8°C(±5°F)

|

I,O |

|

*: |

LT = Low temperature range, HT = High temperature range |

|

**: |

I = Inert media, O = Oxidizing media, R = Reducing media, V = Vacuum |

|

|

Constantan, Alumel, and Chromel are trade names of their respective owners. |

thermocouple wire K type

Type K (Chromel / Alumel)

Type K is the ‘general purpose’ thermocouple. It is low cost and, owing to its popularity, it is available in a wide varietyof probes. Thermocouples are available in the -200 °C to +1200 °C range. Sensitivity is approx 41 µV/°C. Use type K unless you have a good reason not to.

Type E (Chromel / Constantan)

Type E has a high output (68 µV/°C) which makes it well suited to low temperature (cryogenic) use. Another property is that it is non–magnetic.

Type J (Iron / Constantan)

Limited range (-40 to +750 °C) makes type J less popular than type K. The main application is with old equipment that can not accept ‘modern’ thermocouples. J types should not be used above 760 °C as an abrupt magnetic transformation will cause permanent decalibration.

Type N (Nicrosil / Nisil)

High stability and resistance to high temperature oxidation makes type N suitable for high temperature measurements without the cost of platinum (B,R,S) types. Designed to be an ‘improved’ type K, it is becoming more popular.

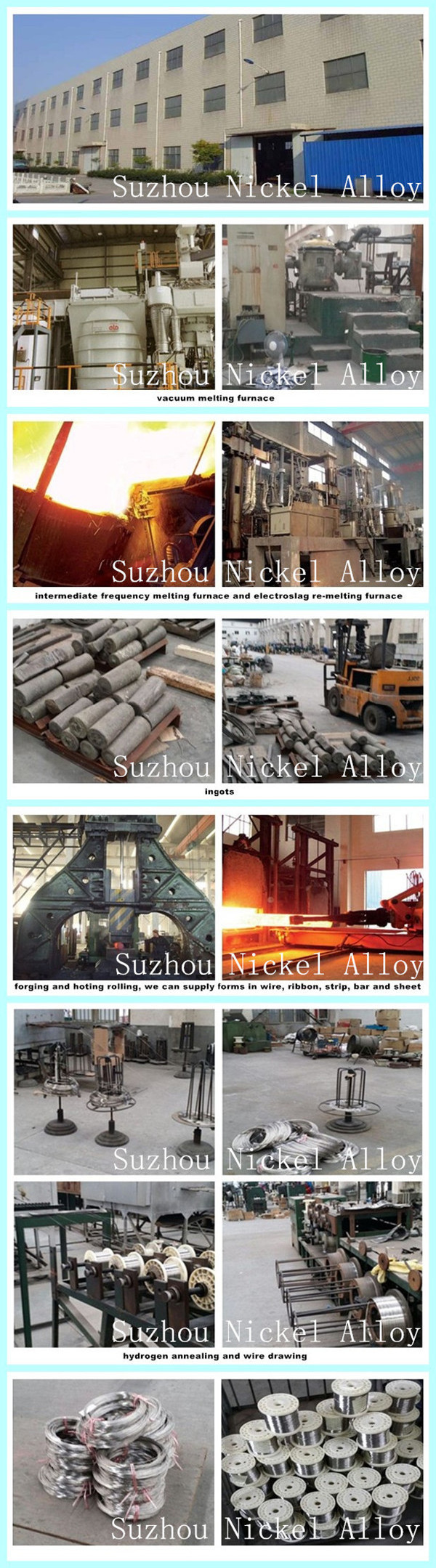

WHY CHOOSE SZNK HIGH QUALITY Thermocouple wire?

1.Competitive price ,

We are manufacture, so you get directly from factory that is actively controlling for mutual benefit.

2.Quality Control System

With experienced engineers and QA workers, each manufacturing process is checked and audited strictly. Incoming quality control conducts inspections and handle quality issues before the assembly process starts. Our In-Process Quality Control process governs our quality systems during the assembly process in order to detect and handle any problems that may arise during assembly. Outgoing quality assurance is the last process before products ship to customers, and hence is very important in ensuring our shipment is defect-free. Numerous redundancies with IQC and IPQC exist here to ensure the validity of previous processes.

3.OEM services

The factory can produce the product according to the client's engineering drawings. Client's mark can be labeled on packaging for OEM products.

4.Short lead time and prompt shipment

How to contact us?

Send your inquiry details in the below for free sample , click "send" now.

Whatsapp: +86 15027781894