Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xiinhe Machinery

-

Voltage:

-

220/380/440V 50/60HZ 3Phase, 220/380/440V 50/60HZ 3Phase

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

37

-

Weight:

-

4800 KG, 10T

-

Product:

-

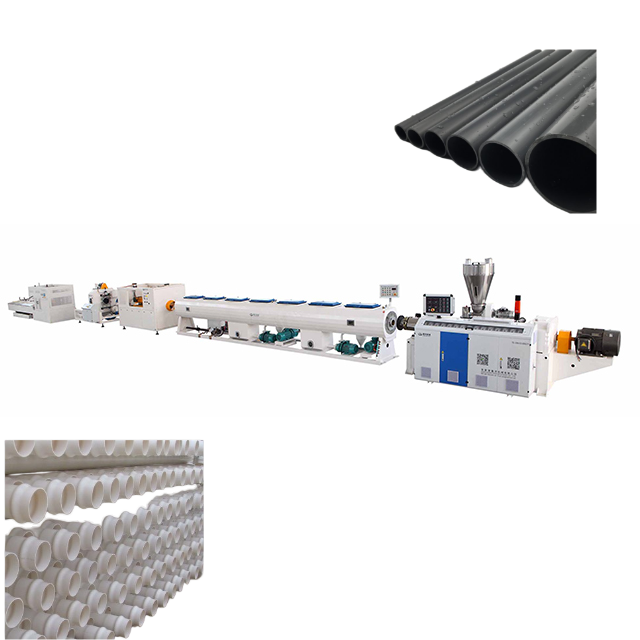

Plastic Water Tube Production Line pvc pipe making machine

-

product diameter:

-

16mm-800mm

-

Raw material:

-

PVC Powder,CaCa3

-

Product Type:

-

water supply pipe , drain pipe

-

Inverter:

-

TECO Brand

-

Electric:

-

Scheider Germany

-

Controlled by:

-

Siemens PLC

-

Temperature controller:

-

Omron Brand

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Xiinhe Machinery

-

Voltage:

-

220/380/440V 50/60HZ 3Phase, 220/380/440V 50/60HZ 3Phase

-

Dimension(L*W*H):

-

20mx2.5mx2.2m

-

Power (kW):

-

37

-

Weight:

-

4800 KG, 10T

-

Product:

-

Plastic Water Tube Production Line pvc pipe making machine

-

product diameter:

-

16mm-800mm

-

Raw material:

-

PVC Powder,CaCa3

-

Product Type:

-

water supply pipe , drain pipe

-

Inverter:

-

TECO Brand

-

Electric:

-

Scheider Germany

-

Controlled by:

-

Siemens PLC

-

Temperature controller:

-

Omron Brand

Overview

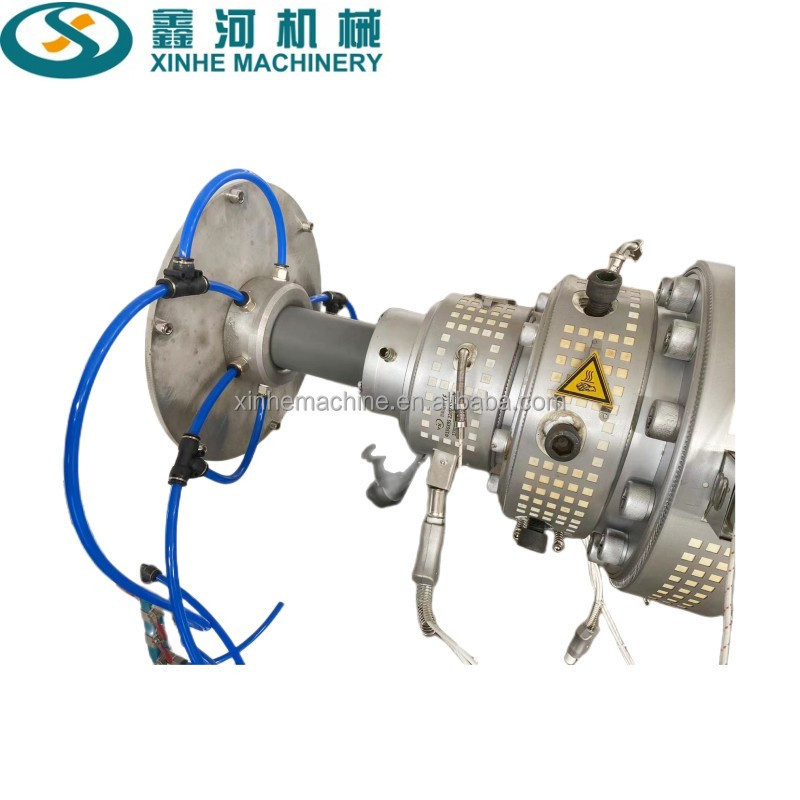

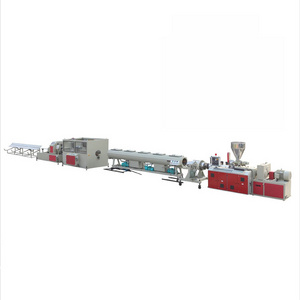

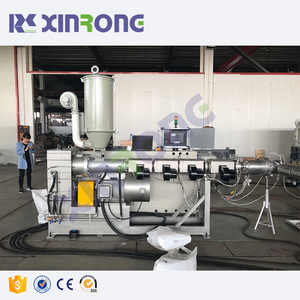

The pvc pipe production line's principle:first we put the materials into the screw loader,then we begin to put them to the extruder.By pressing in the screw barrel,to the molds,withing sizing sank to cool the product to be shaped.After that we use tractor and cutter to haul ,to cut.At last ,we use the stacker to put ,or a belling machine to bell the pipe.

First Glance

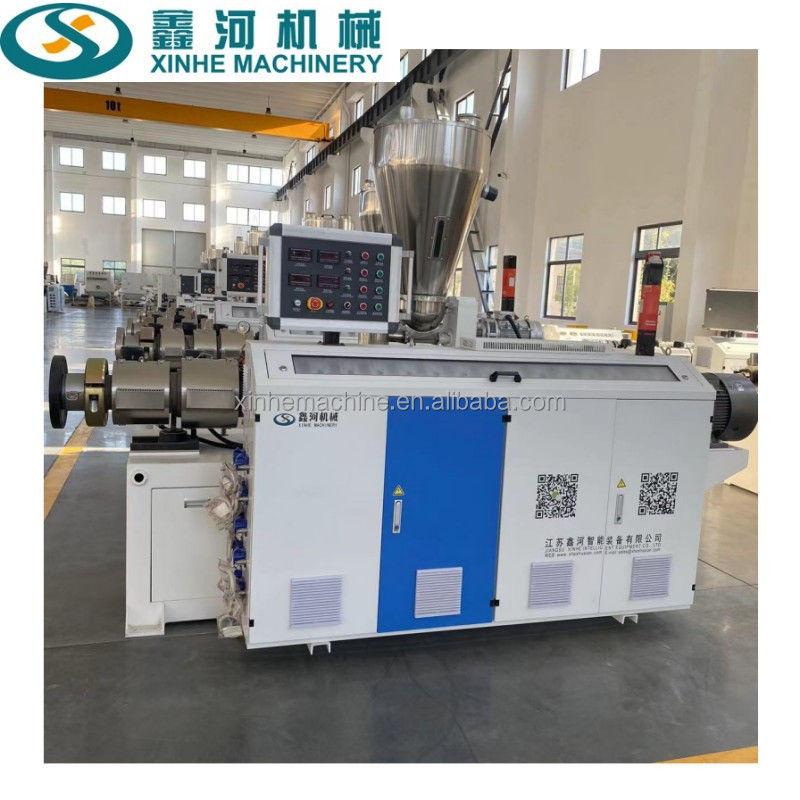

The extruder we mainly use sjsz65/132.It includes two screws ,a barrel, a motor a gear box and so on.

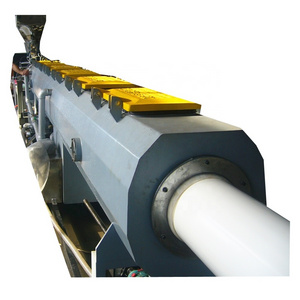

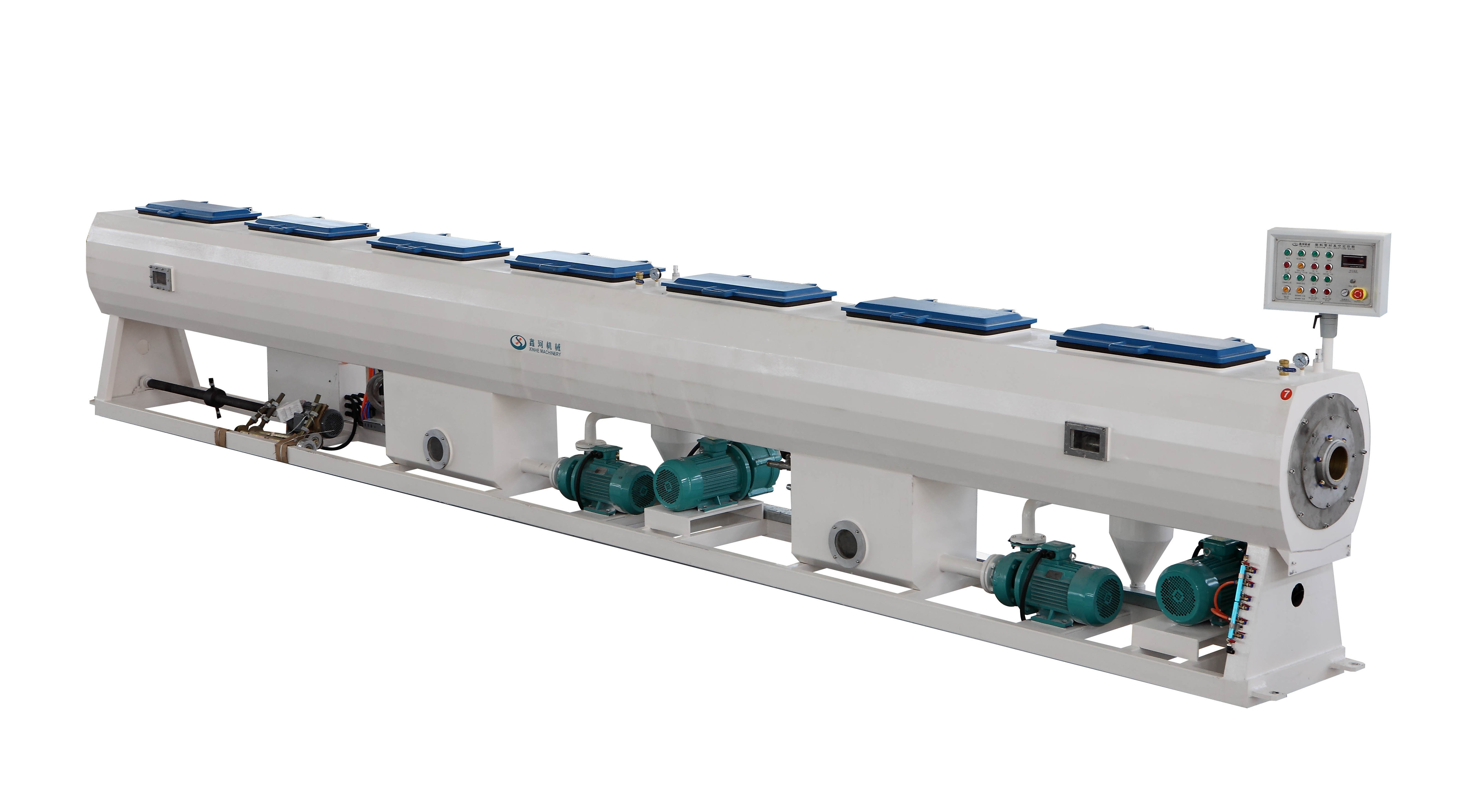

The vacuum tank mainly includes water pump and vacuum power with a electric bin.

As for the tractor of pipe, we can use two-claw tractor .It mainly used in small diameter.For the large, we use three-claw tractor.

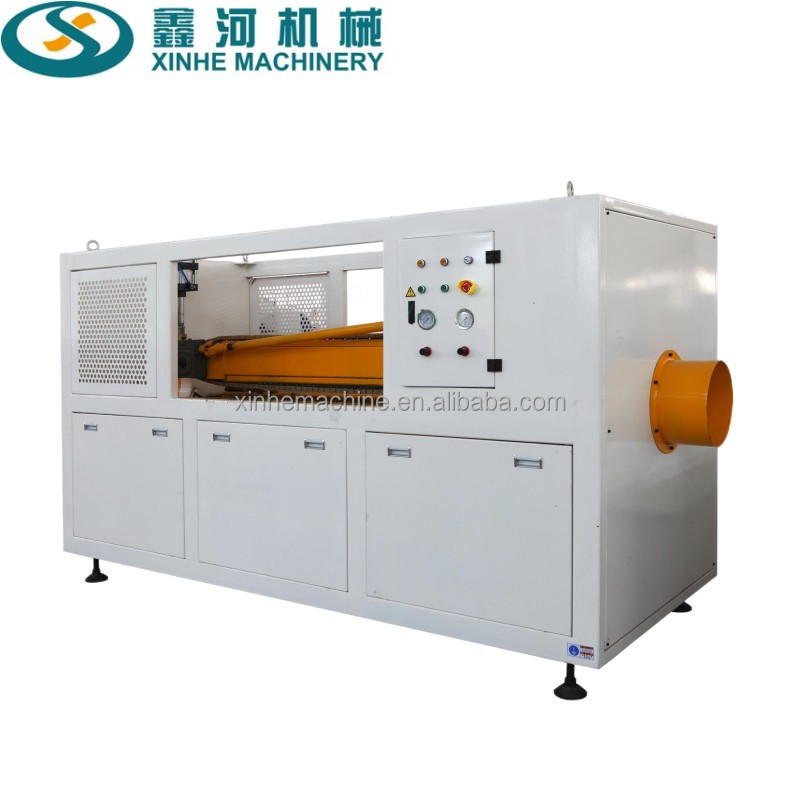

For the small diameter of pipes, we use saw type cutter and we main use planet cutter for the large diameter.

product parameters

|

Screw diameter

|

¢65/132

|

Capacity

|

200-250

|

|

Length of Screw

|

1440

|

Barrel heating method

|

Aluminum heating ring

|

|

Screw rotation speed(r/min)

|

1-37

|

Barrel heating power(kw)

|

24

|

|

Screw barrel material

|

38CrMoALA

|

Barrel cooling method

|

1/2HP blower cooling

|

Recommend Products

Hot Searches