Advantage

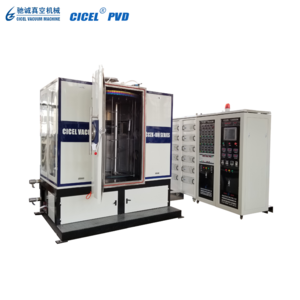

*Suits for your limited factory space.

*Seeking for limited budget solutions.

*Saves manpower that ensures productivity.

*Continuous batch production.

*Seeking for limited budget solutions.

*Saves manpower that ensures productivity.

*Continuous batch production.

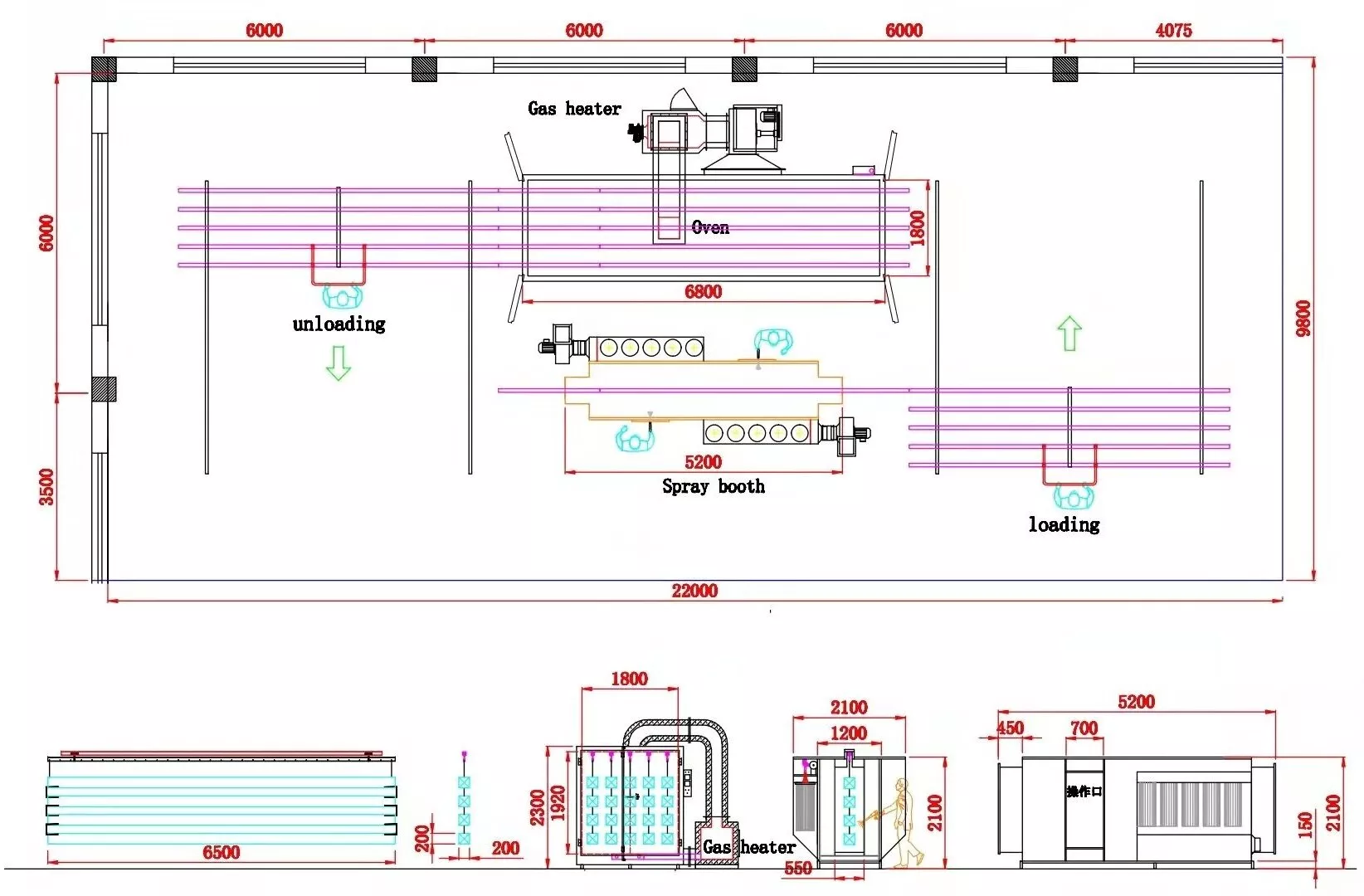

Our powder coating line includes

:

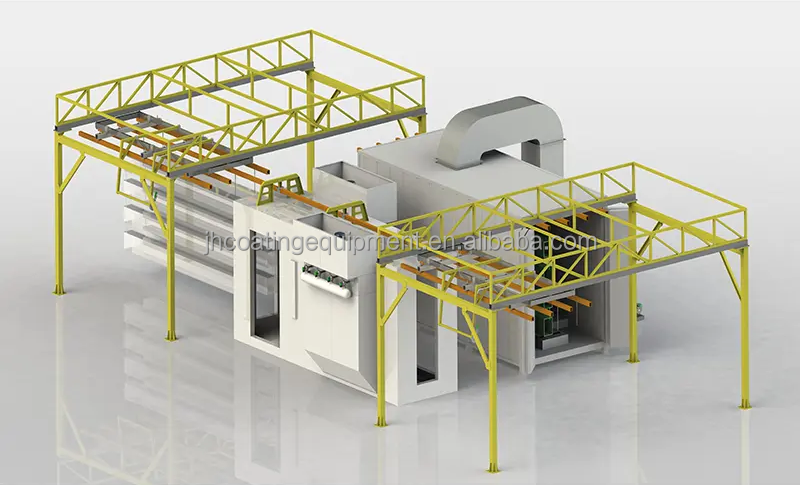

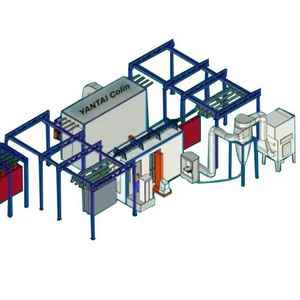

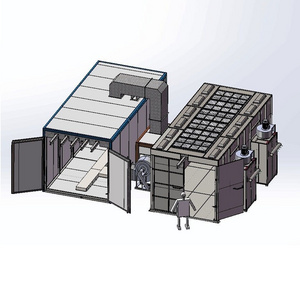

→ A pass-through powder booth with filter recovery

→ A curing oven with top tracks

→ A transport conveyor system

→ A set of manual powder coating machine

→ A transport conveyor system

→ A set of manual powder coating machine