- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM

-

Mould material:

-

P20, H13, 718, NAK80

-

Cavity:

-

Single or Multi Cavity

-

Mould base:

-

LKM, HASCO, DME etc

-

Part material:

-

PC/ABS, ABS, PC, PA, PMM etc

-

Mould life:

-

50,000-1,000,000

-

Product Name:

-

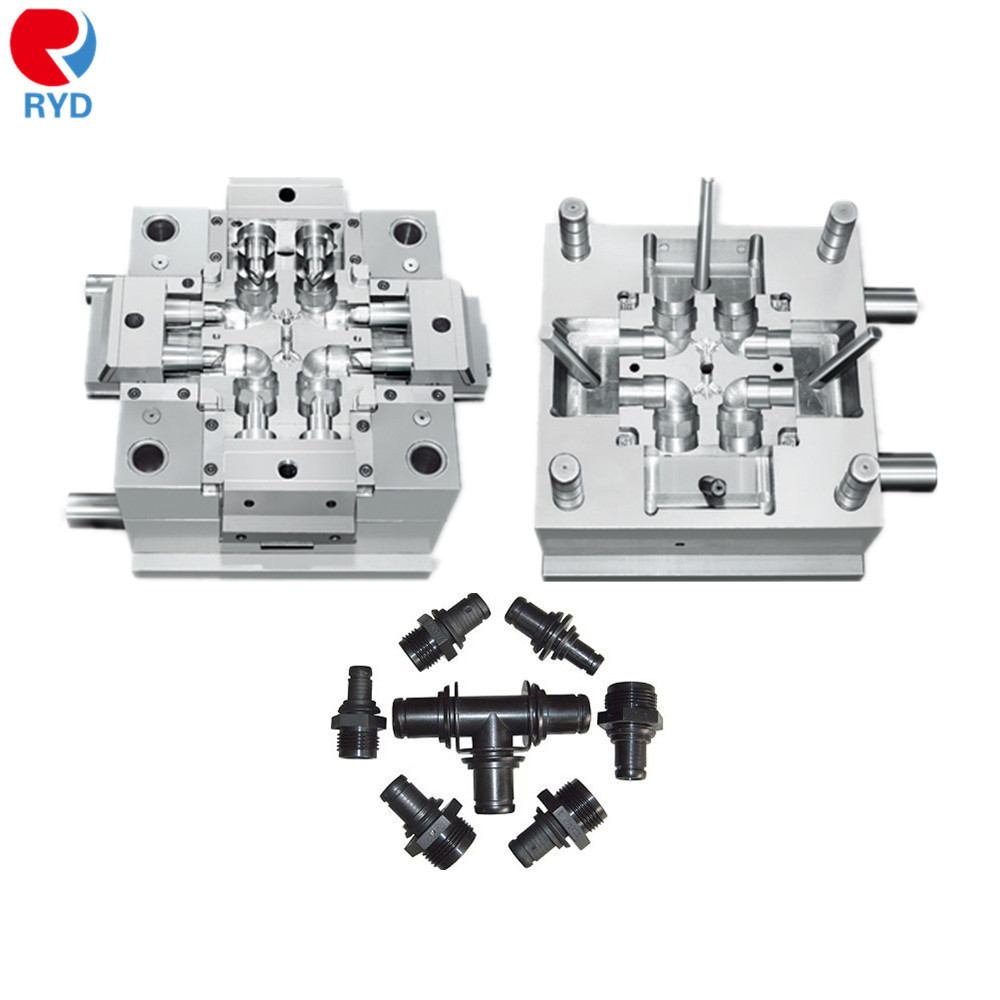

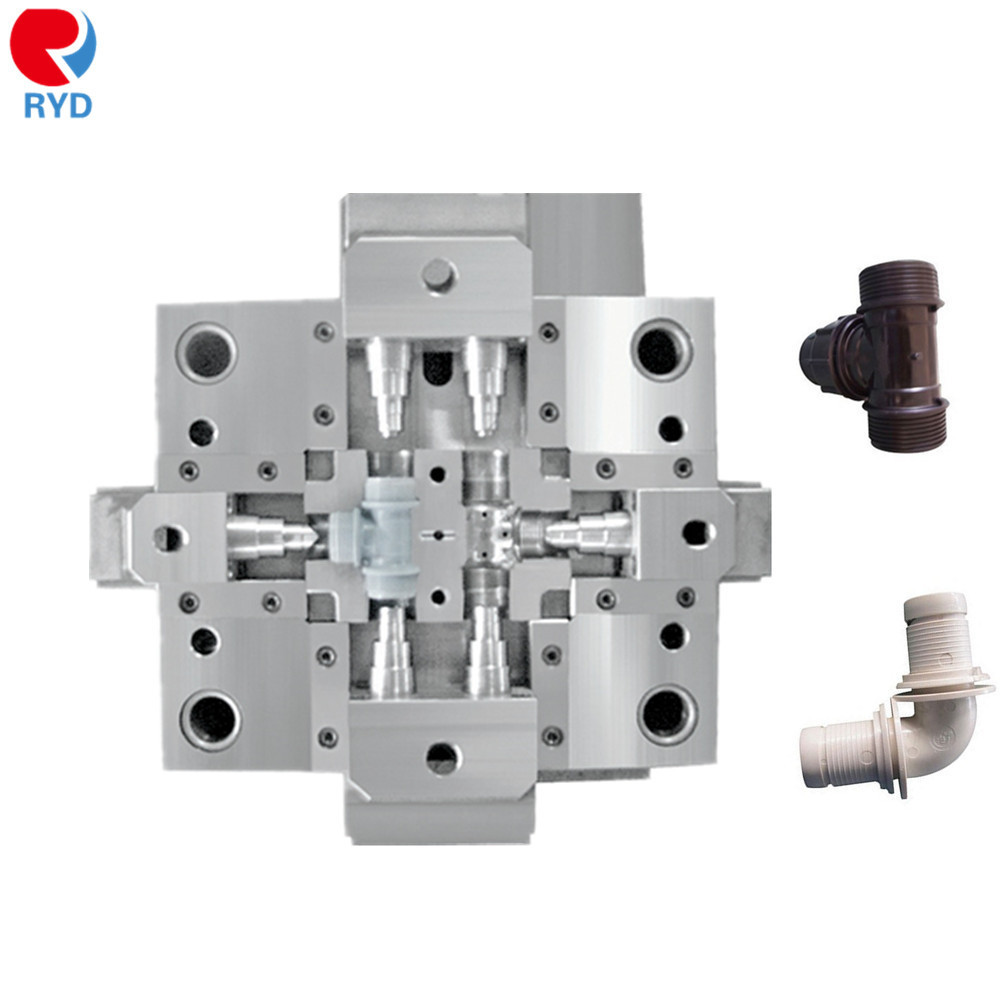

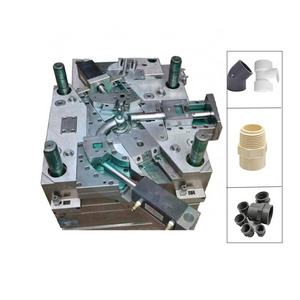

plastic injection pipe fitting mold with factory price

-

Runner:

-

Cold Runner+ Subgate

-

Process:

-

Injection Mould Plastic Part

-

Design:

-

3D/2D(UG/Pro-e/CAD)

-

Delivery Time:

-

15-20 Days

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

RIYADH

-

Model Number:

-

OEM

-

Mould material:

-

P20, H13, 718, NAK80

-

Cavity:

-

Single or Multi Cavity

-

Mould base:

-

LKM, HASCO, DME etc

-

Part material:

-

PC/ABS, ABS, PC, PA, PMM etc

-

Mould life:

-

50,000-1,000,000

-

Product Name:

-

plastic injection pipe fitting mold with factory price

-

Runner:

-

Cold Runner+ Subgate

-

Process:

-

Injection Mould Plastic Part

-

Design:

-

3D/2D(UG/Pro-e/CAD)

-

Delivery Time:

-

15-20 Days

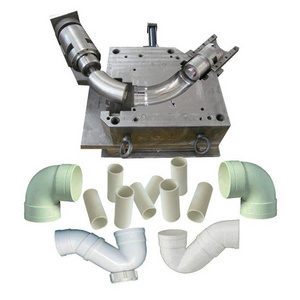

Product name : plastic injection pipe fitting mold with factory price

Product Specifications

Detail

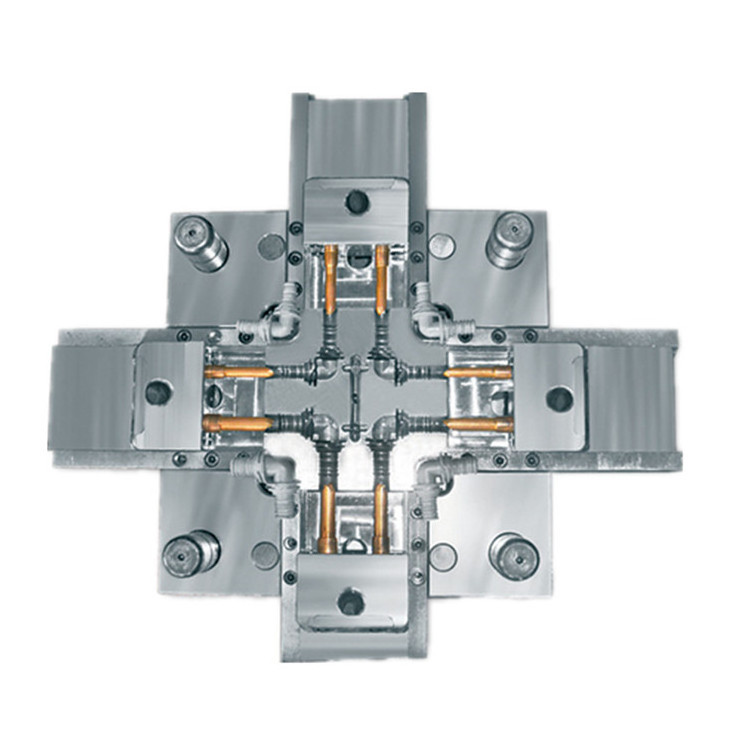

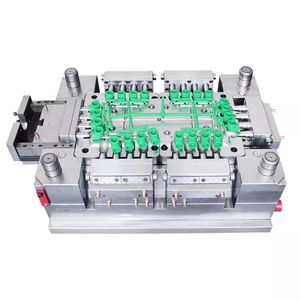

Mould Cavity: 2cavities or 4 cavities

Injection Cycle Time:90s

Mold Life: one million shots

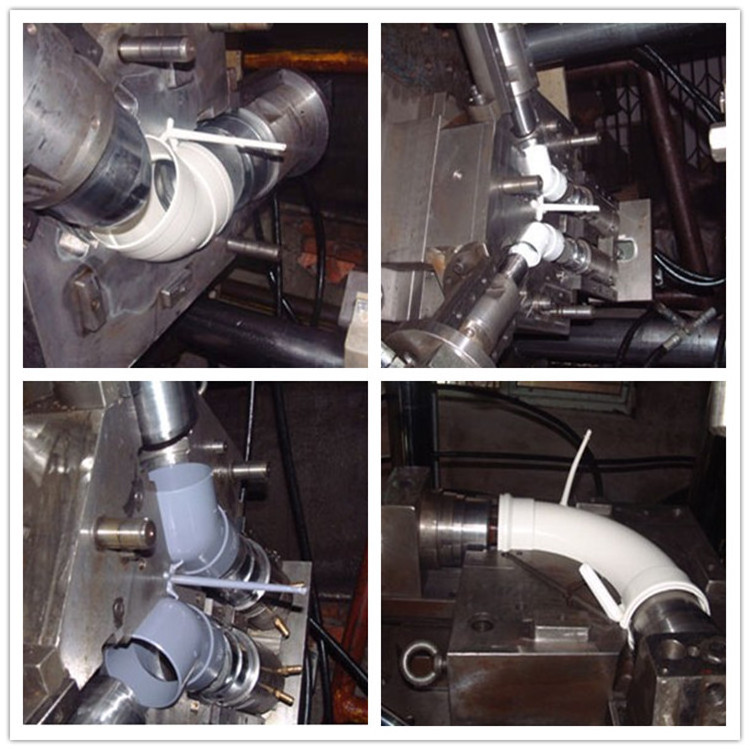

Demoulding: automatic

Design Software: UG,Pr/E, Solid works, CAD

Delivery Time:50 days

Warranty: one year, free of charge Mould features: Excellent precision control for demension tolerance and shrinkage With intensive cooling system, optimal air venting, shining polish, advanced mould design Superior impact and abrision resistance for the moulds

Important Note:

1. The injection mold is customized for our clients.

2. We do not sell ready-made injection mould, but custom injection mould . So, no price list available.

3. Quotation available after discussion on requirements and design.

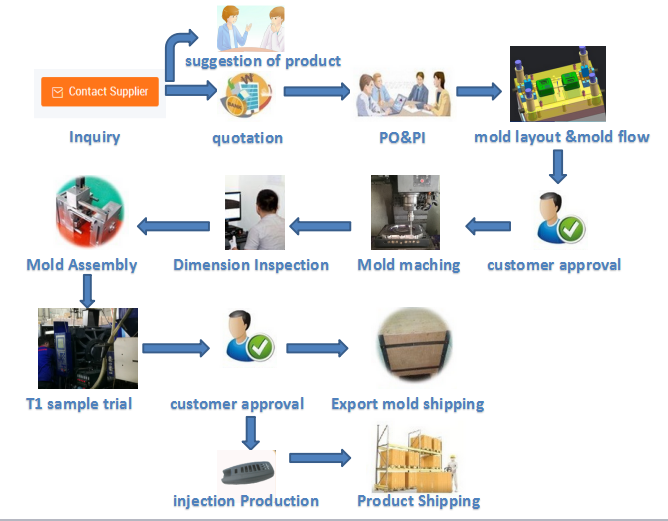

Then How To Custom Your Own Injection Mould?

|

Steps |

DETAIL |

|

1.Enquire /Quote |

Discuss with customer after received buyer’s samples or drawings. |

|

2.Negotiation |

Quality,Technique requests,Mould material,Price,Delivery time,Payment,etc. |

|

3.Place order |

Sales contract + proforma invoice. |

|

4.prepaid |

Customer T/T deposit to us to start to design mould. |

|

5.Mould design |

We will communicate&exchange the opinion with customers during making drawing according to the sample. |

|

6.Design confirmation |

Send mould drawing to customer for confirmation. |

|

7.Mould processing |

Start to manufacture, we will sent photos to show tooling process. |

|

8.Sample confirm |

Send the sample or as negotiation. |

|

9.Mass production |

If customers need mass production plastic products, We can also offer. |

• Strick Quality Control System: As an experienced manufacturer ofplastic mold and products, we will make sure with you the high quality products.

• Superior Service: Our professional sales staffs who are fluent in English, can answer you technic question timely.

• Stability and Reasonable Price: We manufacture the molds and products in our factory, which can help you save cost and enable good quality.

• Speed Delivery: Mould delivery time is 20-45 days according to its structure and size, and then another 7-20days for mass production according to different order quantity.

The procedure for plastic mold or products in our company :

1. Our engineers follow the molds' production every week to make sure all of them are in schedule;

2. After trial production, we will check the samples to make sure all are right 3. We will send the sample and dimension report to our clients for approval

4. After everything is ok, we will do final inspection on the molds and products before shipment.

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

20-45 days after confirming order,detail delivery date should be decided according to

production season and order quantity.