- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

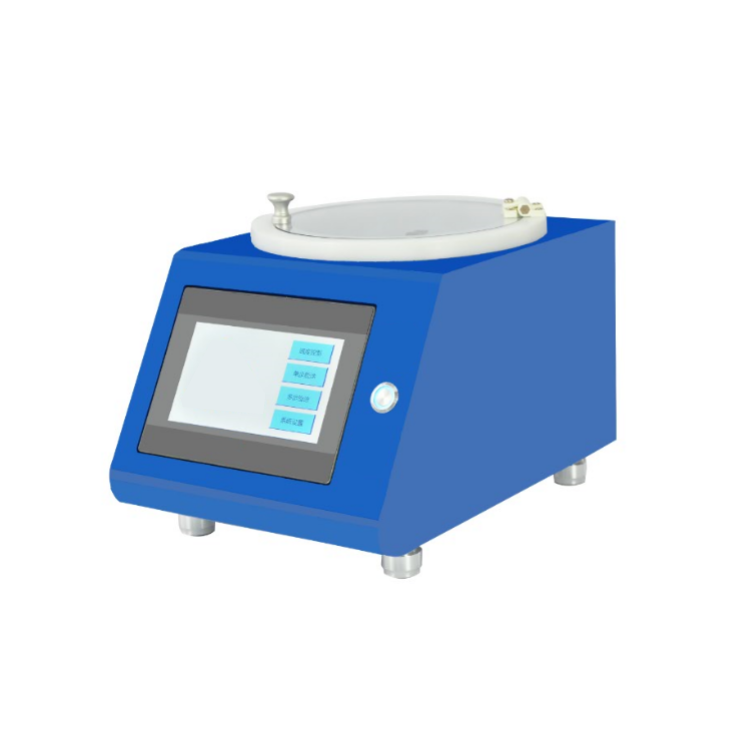

Vacuum Optical Coating Machine

-

Vacuum Pump:

-

120L/min Oilless Vacuum Pump

-

Spin Speed:

-

500 - 8000 RPM

-

Input Power:

-

110VAC or 220VAC

-

Motor Power:

-

24V DC motor with 150W Max.

-

Product Dimensions:

-

13''(L) x 10''(W) x 8.5''(H)

-

Net Weight:

-

15 kg (33 lbs)

-

Weight:

-

15KG

-

Certification:

-

CE/TUV

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Online support

-

Application:

-

Decorative Coating

-

Product name:

-

Vacuum Optical Coating Machine

-

Vacuum Pump:

-

120L/min Oilless Vacuum Pump

-

Spin Speed:

-

500 - 8000 RPM

-

Input Power:

-

110VAC or 220VAC

-

Motor Power:

-

24V DC motor with 150W Max.

-

Product Dimensions:

-

13''(L) x 10''(W) x 8.5''(H)

-

Net Weight:

-

15 kg (33 lbs)

-

Weight:

-

15KG

-

Certification:

-

CE/TUV

TN-VTC-100A is CE certified compact spin coater with vacuum chucks designed for easy and quick coating via sol-gel for wafers up to 4". The spinning speed is variable from 500-8000 rpm with two programmable segments. The package comes included with complete accessories for immediate use.

SPECIFICATIONS:

|

Structure

|

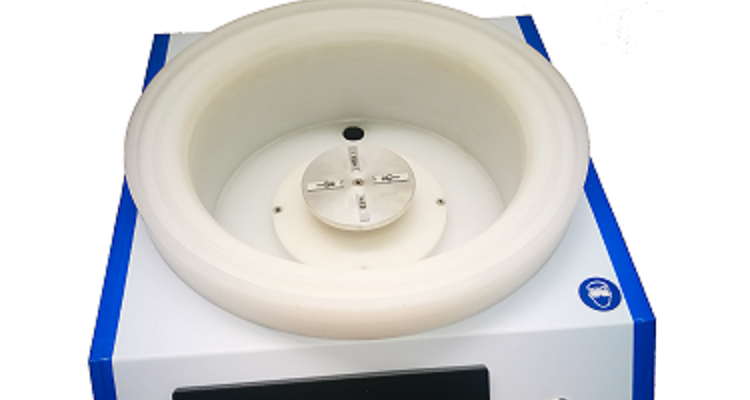

Aluminum casting case to keep spinning stable Liquid disk made of Polypropylene (PP ) to resist most of the corrosive solutions Drainage outlet and vacuum pump connector are on back panel One filter is included in standard package. It is used to connect the coater for preventing waste wate flowing into the pump The spin coater can be used in glovebox with Ar g or N2 gas, but pump must be put in outside glovebox via a feedthrogh). One oil-less vacuum pump is included in the standard package, please click here for specification details. |

|

|

Chamber Diameter: 145 mm 3 sets of PP anti-corrosive vacuum chucks with chuck o-ring come in different sizes (1'', 2'' and 4'') 1 piece of adhesive tape (6'' W x 24'' L) is included for coating irregularly shaped substrates (e.g. Place the irregular substrate on the adhesive tape, then the vacuum chuck will hold the tape by suction) Mini suction cups are available for the small wafer with less 1" Dia. or substrate with regular ( 5x5, or 10x10mm) or irregular shape. |

|

Vacuum Pump |

One 120L/min Oilless Vacuum Pump is included. For Ar glove box user, Please consider our 24VDC vacuum pump with no feedthrough required. Vaccum grade rubber pipe is included for immediate use. |

|

|

Digital control panel with two programmable segments of different spin times (1~60s) and speeds 500 - 8000 RPM adjustable spinning speed |

|

Liquid Injecting |

20mL syringe is used to contain the coating material The syringe holder height can be adjusted and rotated freely along the support rod |

|

Optional |

You may choose Precision Electronic Single Channel Pipette: 20 - 200uL for more accurate coating Using plasma cleaner to treat substrate surface before coating can improve film quality You may consider our new product: Heatable syringe Vacuum Flash Assembly for DIY Vacuum Flash-Assisted Solution Process (VASP), Up to 5 mTorr is available |

|

Input Power |

110VAC or 220VAC please select the voltage in options bar (10A fuse) |

|

Motor Power |

24V DC motor with 150W Max. |

|

Product Dimensions |

13''(L) x 10''(W) x 8.5''(H) |

|

Net Weight |

15 kg (33 lbs) |

|

Compliance |

CE Certified NRTL certification is available upon request at extra cost ( Please notice us before ordering if you need NRTL ) |

|

Warranty |

One year limited with lifetime support Rusting and damage due to improper storage condition or maintenance are not covered by warranty |

|

|

In order to achieve optimal coating quality, please consider cleaning substrates by a plasma cleaner prior to coating. This will significantly reduce the surface tension on the substrates. Cleaning instruction for the spin coaters.

You may consider our new product: Heatable syringe and spin coater with heatable cover Strongly suggest you put the coater under a fume hood as below right When using the coater in glovebox with Ar gas, vacuum pump must put in outside the glovebox via vacuum feedthrough or adaptor |

|

Warnings |

Do not overflush the water bowl/base with any kinds of liquid. Excess liquid will leak into the motor shaft and cause damage. Please use fabric cloth to wipe out the residues remain in the bow/base. If necessary, turn on the water outlet when flushing the water bowl/base to avoid liquid overflowing during the operation. For more details about the cleaning procedure, please review the cleaning instruction for the spin coaters.

|

|

Shipping Dimensions |

40"(L) x 28"(W) x 24"(H) |

|

Shipping Weight |

46 kg (100 lbs) |

|

STANDARD PACKAGE: |

||||

|

Item # |

Description |

Qty |

||

|

1 |

VTC-100A Desktop Spin Coater |

1 |

||

|

2 |

4" Vacuum Chuck (pre-installed on the machine) |

1 |

||

|

3 |

2" Vacuum Chuck |

1 |

||

|

4 |

1" Vacuum Chuck |

1 |

||

|

5 |

Plastic Glass Cover for operation safety (pre-installed on the machine) |

1 |

||

|

6 |

20mL Syringe for dropping coating solvent on the plate |

1 |

||

|

7 |

Hose for connecting vacuum pump |

1 |

||

|

8 |

Drain Hose for water outlet |

1 |

||

|

9 |

Oil-less vacuum pump, AC 110V or 220V version

with

Filter installed on pump

as a whole set

|

1 |

||

|

10 |

Blue Adhesive Tape (6" W x 24" L)

|

1 |

||

|

Optional Parts

|

||||

|

Option |

Chuck O-ring For VTC200 OR VTC100

|

Option |

||

Founded in 2005, Zhengzhou Tainuo Film Materials Co., Ltd. is a company specializing in the development and production of laboratory technology research equipment. The products are mixed, pressed, burned, cut, ground, polished, coated, analytical equipment and related consumables. Products include laboratory sintering equipment, coating equipment and so on. At present, it has been exported to 25 countries and regions such as the United States, Europe, and Southeast Asia, and has been well received by various scientific research units.

We have a mature technology research and development team, the number of technicians is 33, the company has 150 people, more than 500 square meters of office space, the factory covers an area of about 1,500 square meters located in Zhengzhou High-tech Zone Electronic Industrial Park. The products are mainly located in the research market, serving scientific research in the labs of universities and colleges, and can also customize products according to your needs.

Q. Are you a manufacturer or a trading company?

A. We are professional laboratory instrument manufacturers, have their own design team and factory, have mature technical experience, and can guarantee the quality of products and the optimal price.

Q. How is your company's product after-sales service system?

A. The product warranty period is 12 months, we can provide lifetime maintenance. We have professional pre-sales and after-sales departments that can respond to you within 24 hours to resolve any technical issues.

Q. How long is your delivery time? If I want to customize the instrument, how long does it take?

A. 1. If the goods are in stock, it is 5-10 days. 2. We can provide customized services for our customers. It usually takes 30-60 days depending on the specifications of the custom instrument.

Q. Our country's power supply and plug are different. How do you solve it?

A. We can supply a transformer and plug according to your local requirements according to the power plug of different countries.

Q. How to pay?

A. T / T, L / C, D / P, etc., it is recommended to use Alibaba Trade Guarantee.

Q. How is the package of goods? Delivery methods?

A. 1. Standard export fumigation sign wooden box packaging 2. Express, air, sea shipping according to customer requirements, find the most suitable way.

More questions, please contact customer service