If you are finding a

Trustworthy Filling Machine Manufacturer & Long-Term Oversea Partner

, Hengyu is your first choice!

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

OEM

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HENGYU

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

KG

-

Function:

-

Filling Capping

-

Bottle type:

-

PET can/aluminum cam

-

Material:

-

SUS304/316

-

Control:

-

PLC+ Touch Screen

-

Electrical component:

-

Seimens

-

Processing Types:

-

Isobaric Pressure Filling

-

Sealing type:

-

Hob sealing

-

Key word:

-

Canning machine

-

Bottle Size:

-

200-2500 Ml

-

CODE:

-

CM001

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Beer, Juice, soft drink

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

OEM

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HENGYU

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

KG

-

Function:

-

Filling Capping

-

Bottle type:

-

PET can/aluminum cam

-

Material:

-

SUS304/316

-

Control:

-

PLC+ Touch Screen

-

Electrical component:

-

Seimens

-

Processing Types:

-

Isobaric Pressure Filling

-

Sealing type:

-

Hob sealing

-

Key word:

-

Canning machine

-

Bottle Size:

-

200-2500 Ml

-

CODE:

-

CM001

——————\uD83D\uDC46Click Above Icons to Learn More \uD83D\uDC46——————

2000+ Successful Case

We have offered

2000+ top filling production lines

from glass bottle, PET, Can, 3-5 Gallon, 3-10L and Daily Products for our valuable global customers during past 18 years.

Original Manufactur

e

100% Self-owned factory Hengyu Beverage Machinery, We provides you with superior quality, fastest lead-time, guaranteed satisfaction and

No Overpay Again!

Money & Cost Saving

Balancing between cost & superior quality benefits. Hengyu focus on

95% Production Efficiency

that

will highlight your product’s benefits.

2020 Top Filling Solution

Product Description

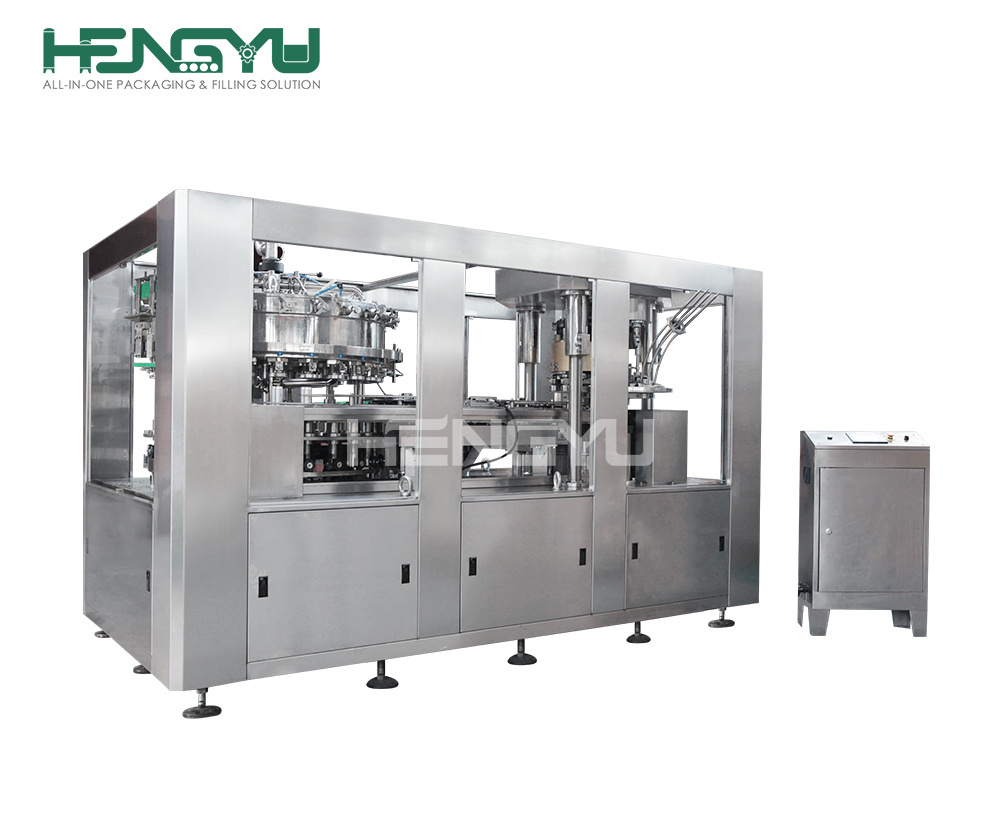

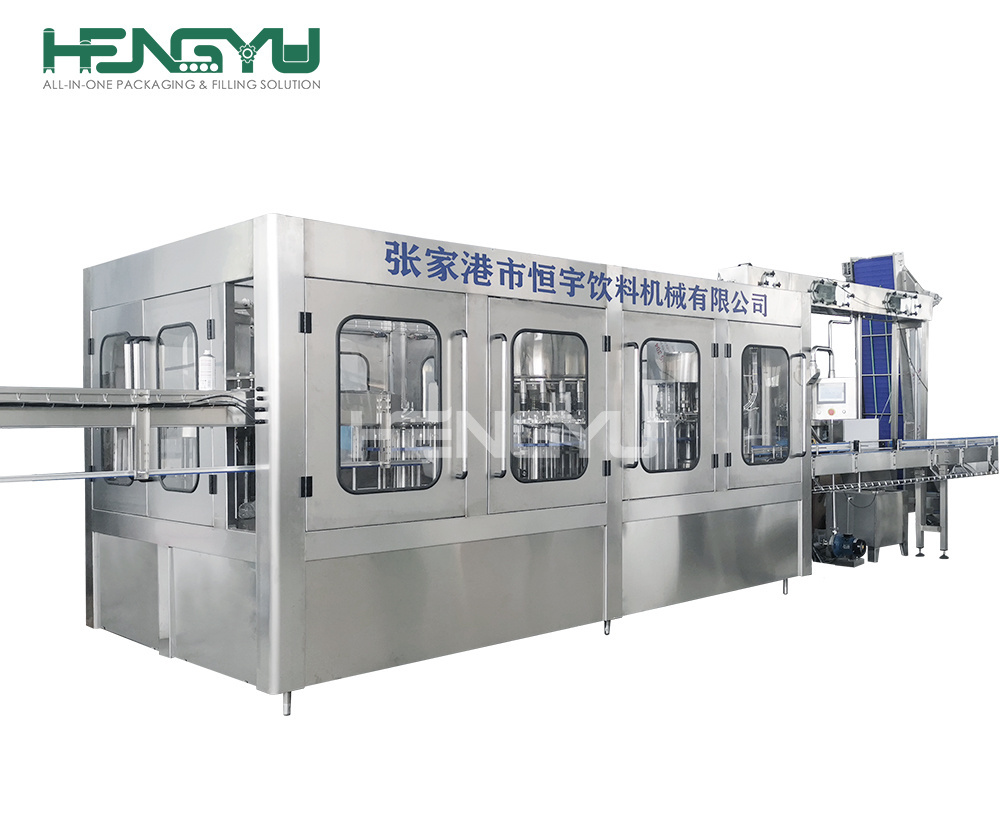

YDGF18-4

Product Capacity:9000BPH@330ml

PET Can/Aluminum Can

- Product Features -

2. This equipment can be used for different material of cans, such as plastic, iron, aluminum and so on ,and the different size of cans is allowed.We can design the equipment according to your requirements

3. It is applicable for isobaric filler and capper of carbonated drinks in beer and drink industry.

4. It is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit.

5. Filling and sealing is the overall designed, power system by filling sealing system to Ensure that both the absolute synchronization and coordination.

6. It adopts the advanced machine, electrical equipment, and Pneumatic control technology.

7. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

8. It can equip long-distance control system according to the Customers request.

9. It is the preferred equipment for the medium beer and beverage plant.

-Technical Parameters-

|

Model (YDGF)

|

12/1

|

18-4

|

36-6

|

|

Filling heads

|

12

|

18

|

36

|

|

Sealing heads

|

1

|

4

|

6

|

|

Capacity (BPH)

|

2000

|

9000

|

18000

|

|

Power(kw)

|

2.2

|

5.0

|

7.5

|

|

Dimension (mm)

|

2500*1650*1900

|

2900*1850*1900

|

3200*2300*1900

|

|

Weight(kg)

|

2500

|

3500

|

6500

|

-Detailed Images

-

Filling Part

1.It adopts isobaric filling principle and filling valve adopts high precision mechanical valve.

2.It has advantages of fast filling speed, high precision in liquid level and realizing that it only starts to filling when there is a can, otherwise it will stop filling.

3.Using the device structure of filling valve precover device plus supporting can bottom device, it can guarantee the maximum stability of cans when they passing in and out of the filling machine.

4.Filling cylinder braces use worm-gear box going up and down to satisfy cans of different height.

5.Float switches in the filling cylinder ensure a smooth liquid inlet.

Capping Part

1) Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2% .

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2% .

Auxiliary

Water Treatment System

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

Pretreatment System

This project is to design for the carbonated drinks preparation to meet the client’s technics, which includes hot water section,sugar melting section, syrup storage section, sterilizing section, carbon mixing section. This design is popular in the modern beverage field worldwide, with the advantages of high efficiency, energy saving, continuous working, etc.

CO2 Mixer

Mixer is designed and made for improving the proportion of water, syrup and carbonated dioxide. It adopts foreign advanced technology-static mixer to lighten water layer, increase carbonizing time, ensure mixing efficiency. Adopt carbon dioxide back

flow deoxygenation, which can save carbon dioxide and deoxidize. High quality water pump and SEIMENS electrical equipment and other parts make up a complete automatic control system.

flow deoxygenation, which can save carbon dioxide and deoxidize. High quality water pump and SEIMENS electrical equipment and other parts make up a complete automatic control system.

Can Depalletizer

Automatic depalletizer is to unload the palletizing aluminum cans and glass bottles from the palletizing plate with each layer as the unit, and automatically transfer them to other equipment of the filling production line.

It is an essential part of a high-speed production line to improve the efficiency and save labor cost.

Spray Cooling/Warming Tunnel

This machine can reduce the temperature of hot filling drinks to 36 -40 ℃,or increase the temperature of cold filling carbonated drinks to 25-30℃. It is used widely in carbonated drinks,hot tea drinks,juice drinks and production line. After designed.

The specially designed tunnel can also have the function of heat preservation and sterilization

Sleeve Labeling Machine

This machine adopts international advanced technology; cover the circle label on the pet bottle. And then hot shrinking to fix on

the position which bottle body designated. This machine's structure is compact, and suitable for the production line of different

direction and different height.

the position which bottle body designated. This machine's structure is compact, and suitable for the production line of different

direction and different height.

Shrink Film Packing Machine

The machine is suitable for wrapping of such products as pop top, mineral water , bottles. beer, drinks etc. It consists of seven actuating motor, through cooperation with 7 actuating motor to form the product packed with plastic film and several bottles as a group out from the hot shrinking packing machine.

Vision Hengyu

<1> Standardized workshop of total 12,000 square meters.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter,CNC machine,to ensure the precision ofparts.

<2>The equipment will go through 24 hours' testing and running before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter,CNC machine,to ensure the precision ofparts.

<2>The equipment will go through 24 hours' testing and running before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Service

1. Installation & debugging

After equipments reached the workshop of customer, place the equipments according to plane layout we offered. We will arrange seasoned technician for equipments installation, debugging and testing production at the same time to make the equipments reach the rated producing capacity of the line.

3. Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopts new design. The quality,specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. After quality guarantee, we offer technology support and after sales service. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

After equipments reached the workshop of customer, place the equipments according to plane layout we offered. We will arrange seasoned technician for equipments installation, debugging and testing production at the same time to make the equipments reach the rated producing capacity of the line.

2. Training

Our company offers technology training to customer. The content of training is structure and maintenance of equipments, control and operation of equipments. Training is in the workshop of customer. Seasoned technician will guide and establish training outline.After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

Our company offers technology training to customer. The content of training is structure and maintenance of equipments, control and operation of equipments. Training is in the workshop of customer. Seasoned technician will guide and establish training outline.After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3. Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopts new design. The quality,specification and function all meet the demand of contract.

4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. After quality guarantee, we offer technology support and after sales service. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

Packing and delivery

FAQ

1.HOW TO FIND HENGYU MACHINERY?

1/Search Alibaba,Google,Youtube,Facebook and find suppliers and manufacturer,not traders

2/Visit exhibition in different countries

3/Send Hengyu Machinery an request and tell your basic inquiry

4/Hengyu Machinery sales manager will reply you in short time and add instant chatting tool

2.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

1/If we can full-fill your request and you interested in our products,you may pay a visit to Hengyu Machinery site

2/The meaning of visiting supplier,because seeing is believing,Hengyu Machinery with our own manufacture and developed&research team,we can send you engineers and make sure your after sales service.

3.HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

1/Through Alibaba letter guarantee service,it will ensure the on time delivery and the quality of the equipment you want to buy.

2/By letter of credit,you can lock the delivery time easily.

3/After the factory visit,You can ensure the facticity of our bank account.

4.SEE HENGYU MACHINERY HOW TO ENSURE THE QUALITY!

1/In order to ensure the accuracy of each part,we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

2/Each component before assembly needs strictly control by inspecting personnel.

3/Each assembly is in charged by a master who has working experience for more than 5 years

4/After all the equipment are completed,we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

5.THE AFTER-SALE SERVICE OF HENGYU MACHINERY!

1/After finish the production,we will debug the production line,take photos,videos and send them to customers via mail or instant tools

2/After the commissioning,we will package the equipment by standard export package for shipment.

3/According to the customer's request,we can arrange our engineers to customers' factory to do the installation and training.

4/Engineers,sales managers and after-sales service manager will form a after-sales team,online and off line,to follow the customers' project.

1/Search Alibaba,Google,Youtube,Facebook and find suppliers and manufacturer,not traders

2/Visit exhibition in different countries

3/Send Hengyu Machinery an request and tell your basic inquiry

4/Hengyu Machinery sales manager will reply you in short time and add instant chatting tool

2.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

1/If we can full-fill your request and you interested in our products,you may pay a visit to Hengyu Machinery site

2/The meaning of visiting supplier,because seeing is believing,Hengyu Machinery with our own manufacture and developed&research team,we can send you engineers and make sure your after sales service.

3.HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

1/Through Alibaba letter guarantee service,it will ensure the on time delivery and the quality of the equipment you want to buy.

2/By letter of credit,you can lock the delivery time easily.

3/After the factory visit,You can ensure the facticity of our bank account.

4.SEE HENGYU MACHINERY HOW TO ENSURE THE QUALITY!

1/In order to ensure the accuracy of each part,we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

2/Each component before assembly needs strictly control by inspecting personnel.

3/Each assembly is in charged by a master who has working experience for more than 5 years

4/After all the equipment are completed,we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

5.THE AFTER-SALE SERVICE OF HENGYU MACHINERY!

1/After finish the production,we will debug the production line,take photos,videos and send them to customers via mail or instant tools

2/After the commissioning,we will package the equipment by standard export package for shipment.

3/According to the customer's request,we can arrange our engineers to customers' factory to do the installation and training.

4/Engineers,sales managers and after-sales service manager will form a after-sales team,online and off line,to follow the customers' project.

2020 Top Sale - Inquiry to Get Price Today!

Hot Searches