- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Weight:

-

2000 kg

-

Marketing Type:

-

New Product

Quick Details

-

Type:

-

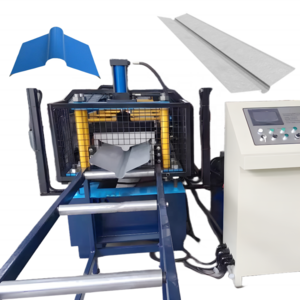

Ridge Cap Roll Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

6-10m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Weight:

-

2000 kg

-

Marketing Type:

-

New Product

Product Description

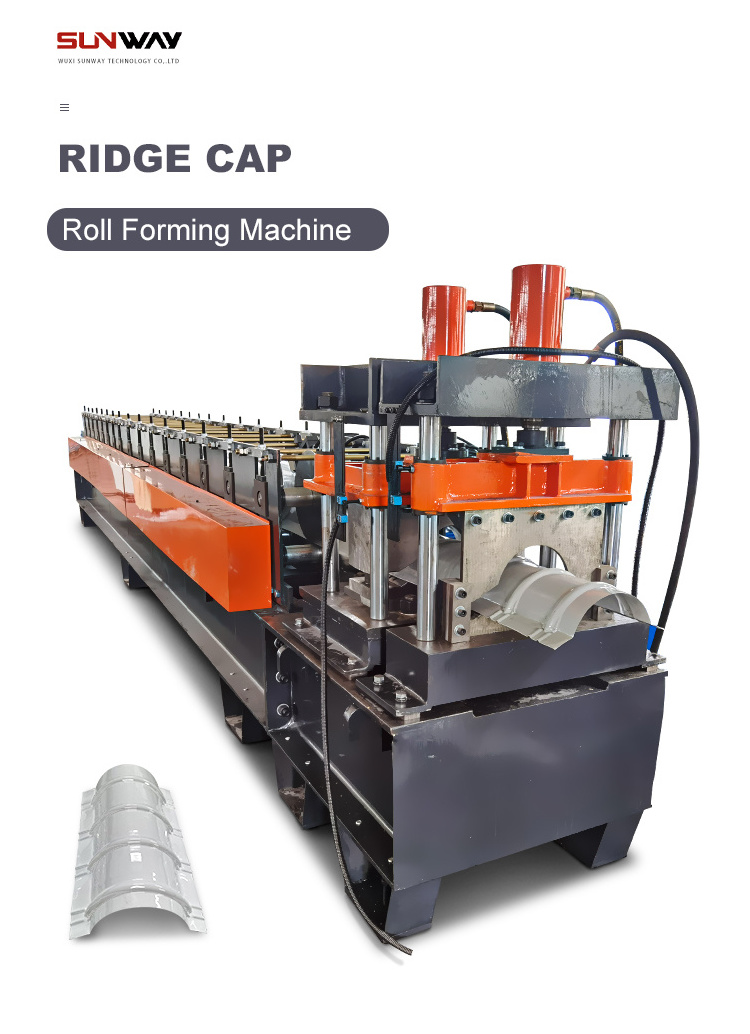

Ridge cap roll forming machine is mainly used to produce ridge cap which is always work with roof tile panels. Normally the panel thickness is 0.3-0.8mm with normal galvanized steel or colored coil.

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile, glazed tile, metal deck, wall panel, standing seam, K span and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Profile Drawings

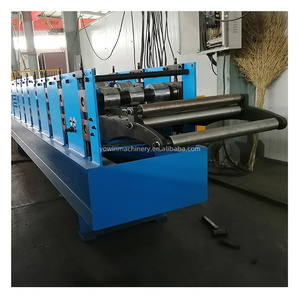

Production Line

Product Details

Hydraulic

Decoiler

Decoiler

Guide Devicing

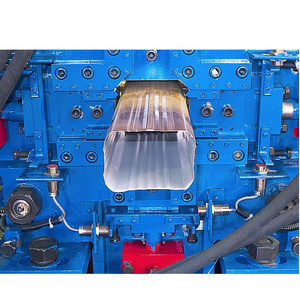

Roll Former

Hydraulic Double Layer Cutting

Out Table

Product Paramenters

|

Ridge Cap Roll Forming Machine

|

|

|

||

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM): 0.3-0.8 According To Your Requirment

|

||

|

|

B) PPGI, PPGL

|

|

||

|

Yield Strength

|

250 - 350 Mpa / 350-550Mpa

|

|

||

|

Tensil Stress

|

350 Mpa-550 Mpa

|

|

||

|

Coil Width

|

As Per The Detailed Profile

|

|

||

|

Forming Speed

|

6-10 (m/min)

|

* Or According To Your Requirment

|

||

|

Forming Station

|

10-18 Stations

|

* According To Your Profile Drawings

|

||

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

||

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

||

|

Machine Structure

|

Steel Plates Welded

|

* Individual Station (Optional)

|

||

|

Rollers’ Material

|

45#

|

|

||

|

Cutting System

|

Hydraulic Post Cut

|

* Hydraulic Servo Tracking Cutter (Optional)

|

||

|

Output Way

|

Roller Table

|

* Auto Stacker (Optional)

|

||

|

Frequency Changer Brand

|

Yaskawa

|

* Siemens (Optional)

|

||

|

Power Supply

|

380V 50Hz 3ph

|

* Or According To Your Requirment

|

||

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

||

Application

Hot Searches