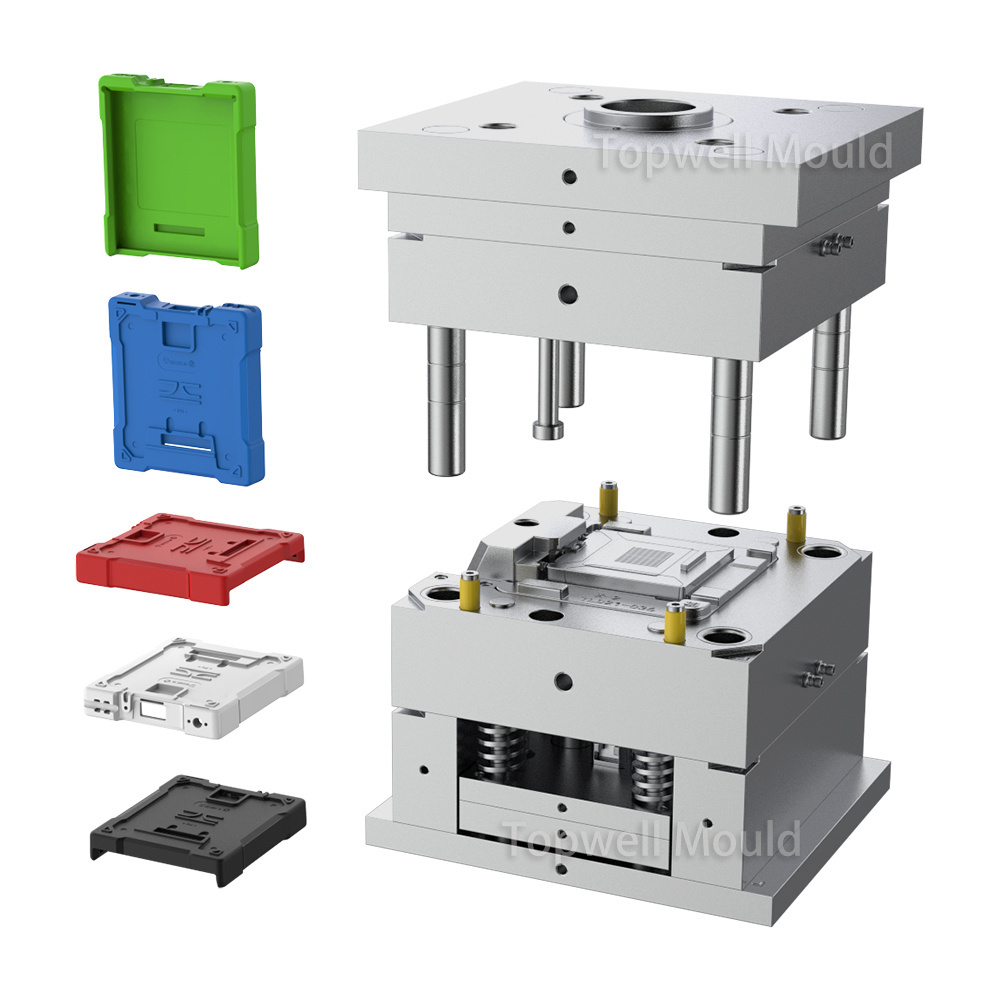

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

New mold J

-

Product Name:

-

Injection Plastic Mould

-

Application:

-

Custom Plastic Molding

-

Mould material:

-

P20/718/738/NAK80/S136

-

Surface treatment:

-

Polish. Etched. Texture

-

Color:

-

Customized Colors

-

Mould Life:

-

250000-300000shots

-

Design software:

-

CAD

-

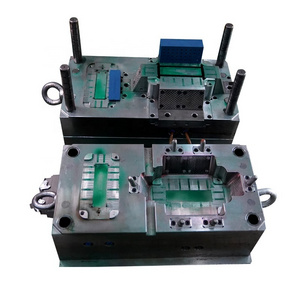

Cavity:

-

Multi Cavity

-

Mould base:

-

LKM.HASCO

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Topwell

-

Model Number:

-

New mold J

-

Product Name:

-

Injection Plastic Mould

-

Application:

-

Custom Plastic Molding

-

Mould material:

-

P20/718/738/NAK80/S136

-

Surface treatment:

-

Polish. Etched. Texture

-

Color:

-

Customized Colors

-

Mould Life:

-

250000-300000shots

-

Design software:

-

CAD

-

Cavity:

-

Multi Cavity

-

Mould base:

-

LKM.HASCO

Specification

|

Place of Origin

|

China

|

|

|

Guangdong

|

|

Brand Name

|

Topwell

|

|

Model Number

|

New mold 01

|

|

Shaping Mode

|

Plastic Injection Mould

|

|

Business Type

|

Manufacturer

|

|

Main Product

|

Product design,Plastic injection mold,Medical part mold,IML/IMD,2K injection mold,Silicone rubber mold,Die casting,Prototype,CNC

Milling... |

|

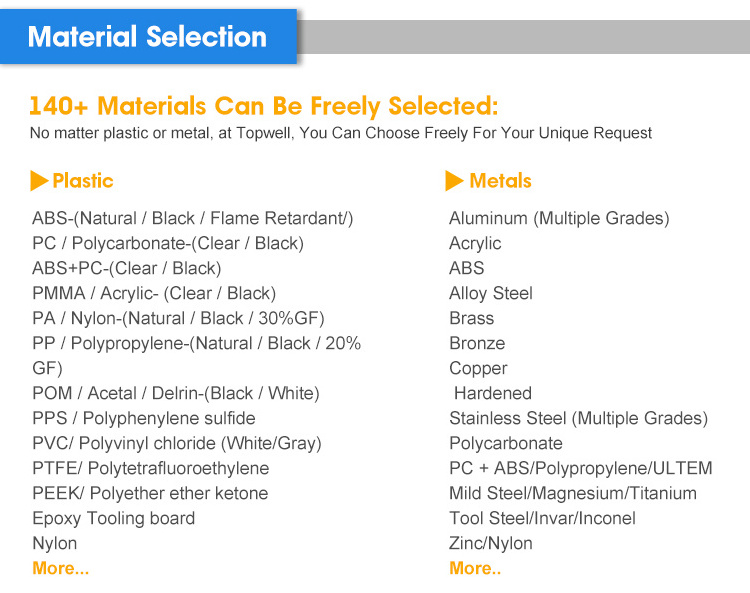

Plastic Material

|

HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc

|

|

Mould Precision

|

+/-0.01mm

|

|

Mould Life

|

50-500K shots

|

|

Mould Cavity

|

Single cavity, multi-cavity.

|

|

|

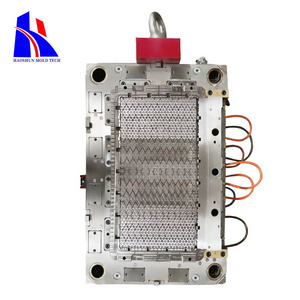

1.Tooling Development Machinery : Swiss Mikron High Efficiency Machining Center,Swiss Mikron High Speed CNC Machining Center,Japan

Makino CNC Milling Machining Center,Taiwan Well Head CNC Machining Center,Swiss Charmilles EDM Machining Center,Japan Makino EDGE 3S Sinker EDM...2.Component Finishing Machinery: Henghui Sing & Bio-Padding Machine,100,000 Grade Oil Spraying Line... 3.Injection Machenery: TOYO Fully Electric Injection Molding Machine Si-Five,YIZUMI Injection Machine,DONGHUA Injection Machine,HAITIAN Machinery,SUMITOMO Injection Machine,HAITIAN Double Molding Machine... |

|

Surface Treatment

|

Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture,

Sanblasting,Gilding, UV Painting… |

|

Product Material

|

Plastic

|

|

Injection machies equipments

|

According to product precision to choice the different model

80T,120T,250T,450T,800T injection machine. |

|

Product

|

Industrial Parts,Communication Parts,Electronics Parts,Medical Parts

|

|

Product Material

|

metal/Plastic/Steel/Aluminium/Ceramic/Iron/Copper/Glass

|

|

Product Name

|

Injection Plastic Mould

|

|

Application

|

Custom Plastic Molding

|

|

Mould material

|

P20/718/738/NAK80/S136

|

|

Surface treatment

|

Polish. Etched. Texture

|

|

Color

|

Customized Colors

|

|

Mould Life

|

250000-300000shots

|

|

Design software

|

Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

|

|

Cavity

|

Multi Cavity

|

|

Quality Control System

|

ISO9001 quality management system certification;ISO14001 environment management system certification;

ISO13485 medical devices quality management system certification |

|

Mould base

|

LKM.HASCO

|

1. Does your company make mould by yourself?

Yes, we are manufacturer with about two decades of molding experience.

2. How many kinds of moulds can you make? Only make the moulds?

We can make many kinds of moulds, such as plastic injection moulds, blowing moulds,stamping mould,die casting moulds and silicone

rubber moulds. Besides, we also can produce the final parts for you.

3. What's the software you will use to check the drawing? And what's format of drawing you can check?

Our designers and engineers all use AUTO CAD and Soliworks software to check 2D and3D drawings.

We can check the drawings with PDF, Al, DWG(CAD)and STP (3D)or IGS(3D)formats.

4. Will you send me the free sample?

Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk.

5. How to pack the moulds and products?

For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack

into non-fumigation wooden case.

And as to products, we will pack into standard export cartons or as per customers request to pack.

Yes, we are manufacturer with about two decades of molding experience.

2. How many kinds of moulds can you make? Only make the moulds?

We can make many kinds of moulds, such as plastic injection moulds, blowing moulds,stamping mould,die casting moulds and silicone

rubber moulds. Besides, we also can produce the final parts for you.

3. What's the software you will use to check the drawing? And what's format of drawing you can check?

Our designers and engineers all use AUTO CAD and Soliworks software to check 2D and3D drawings.

We can check the drawings with PDF, Al, DWG(CAD)and STP (3D)or IGS(3D)formats.

4. Will you send me the free sample?

Yes, but you should charge the freight by yourself. We can return the fee if you place a bulk.

5. How to pack the moulds and products?

For moulds, we will be coated one-layer anti-rust oil first, and then also will be covered thin films on the mould, finally pack

into non-fumigation wooden case.

And as to products, we will pack into standard export cartons or as per customers request to pack.

Hot Searches