- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YC Sci & Tech

-

Dimensions(L*W*H):

-

145x115x180cm

-

Weight:

-

800kg

-

Certification:

-

CE

-

Type:

-

silk screen printing machine

-

Application:

-

Glass printing

-

Size:

-

80*180cm

-

Belt:

-

Track line

-

Equippt:

-

Loading parts

-

Positioning:

-

Accurate

-

Operation:

-

Simple and quick

Quick Details

-

Condition:

-

New

-

Color & Page:

-

single color

-

Voltage:

-

380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YC Sci & Tech

-

Dimensions(L*W*H):

-

145x115x180cm

-

Weight:

-

800kg

-

Certification:

-

CE

-

Type:

-

silk screen printing machine

-

Application:

-

Glass printing

-

Size:

-

80*180cm

-

Belt:

-

Track line

-

Equippt:

-

Loading parts

-

Positioning:

-

Accurate

-

Operation:

-

Simple and quick

Auto glass screen printing machinery screen printing machine for sale

Yincai Machinery is focues on a line of screen printing equipment and printing ink which help customer making more easier and free on worry. We have 13years experience of machine making with consistent quality, resonable price and profectional after-sales satisfied with customer.

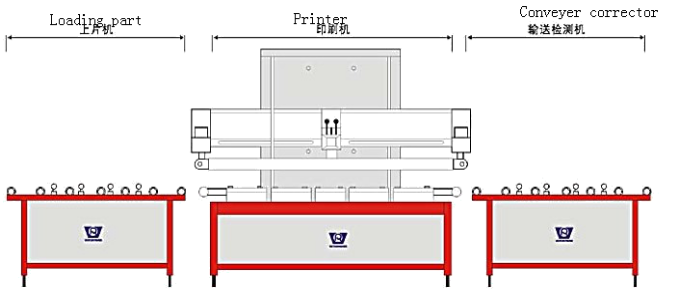

Vertical type automatic screen printing machine

This model biggest printing size is 1300x2500mm, it is work on normal structural glass

Four post automatic screen printing machine (Customized)

P ARAMETERS:

|

Model |

YCQYB-M9060 |

YCQYB-M1280 |

YCQYB-M1680 |

YCQYB-M1808 |

|

Max printing area |

900x600mm |

1200x800mm |

1600x800mm |

1800x800mm |

|

Minimun printing area |

400x300mm |

500x400mm |

700x400mm |

800x400mm |

|

Biggest frame size |

1300x900mm |

1600x1100mm |

2200x1100mm |

2400x1100mm |

|

Thickness avilable |

20mm |

20mm |

20mm |

20mm |

|

Overptint precision |

±0.1mm |

±0.1mm |

±0.1mm |

±0.1mm |

|

Power Source |

380V 50Hz |

380V 50Hz |

380V 50Hz |

380V 50Hz |

|

Air Source |

0.5-0.7MPs |

0.5-0.7MPs |

0.5-0.7MPs |

0.5-0.7MPs |

|

External dimensions |

145x115x180cm |

185x127x180cm |

245x127x180cm |

285x127x180cm |

|

Weight |

800kg |

900kg |

1100kg |

1100kg |

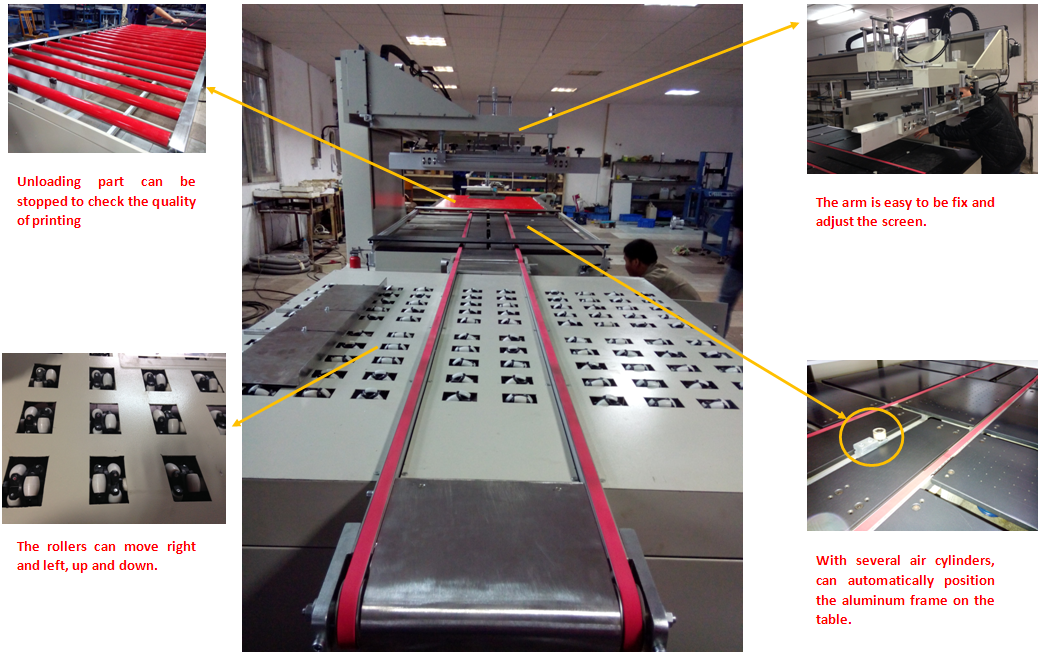

CHARACTER:

1. Integrative speed reducer drives the up and down of printing head, it's quick and steady.

2. High precision guide rail to equip with photosensor synchronization belt drive the printing with frequency conversion, higher precision printing and more steady working.

3. Gas-liquid transformer linked with off-network cylinder, which ensure network off equally and steadily.

4. The fine tuning and locked device of work table is separate, which eliminate the work table locked error.

5. Two cylinders control the squeegee and ink return blade separately, the printing pressure is large and equal.

Match with our glass ink

After printing, Use IR tunel for quik drying (Customized)

If any needed of glass printing, welcome to discuss with me.

Our work shop and factory>>