Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

95 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEGU

-

Voltage:

-

380V-440V

-

Dimension(L*W*H):

-

30M*4M*3M

-

Power (kW):

-

260

-

Weight:

-

18000 KG

-

raw material:

-

PP PE PC granules +Filler masterbatch

-

Processing Type:

-

extrusion machine

-

Extruder:

-

Single screw extruder

-

Output:

-

170-320kg/h

-

Product width:

-

1200--3000 mm

-

Product thickness:

-

1- 6mm,7-12mm

-

Air inflow volume:

-

0.8m3/min

-

Pressure:

-

0.6-0.8mpa

-

Motor:

-

SIEMENS Brand

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

36:1

-

Screw diameter (mm):

-

120 mm

-

Screw Speed (rpm):

-

95 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEGU

-

Voltage:

-

380V-440V

-

Dimension(L*W*H):

-

30M*4M*3M

-

Power (kW):

-

260

-

Weight:

-

18000 KG

-

raw material:

-

PP PE PC granules +Filler masterbatch

-

Processing Type:

-

extrusion machine

-

Extruder:

-

Single screw extruder

-

Output:

-

170-320kg/h

-

Product width:

-

1200--3000 mm

-

Product thickness:

-

1- 6mm,7-12mm

-

Air inflow volume:

-

0.8m3/min

-

Pressure:

-

0.6-0.8mpa

-

Motor:

-

SIEMENS Brand

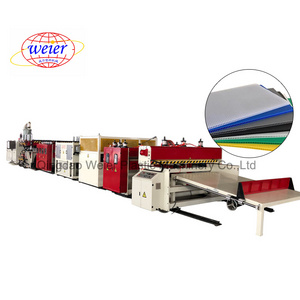

Professional manufacturer for the PP hollow corrugated sheet project

1,Smart automatic easy to operate PP hollow corrugated sheet extrusion machine production line

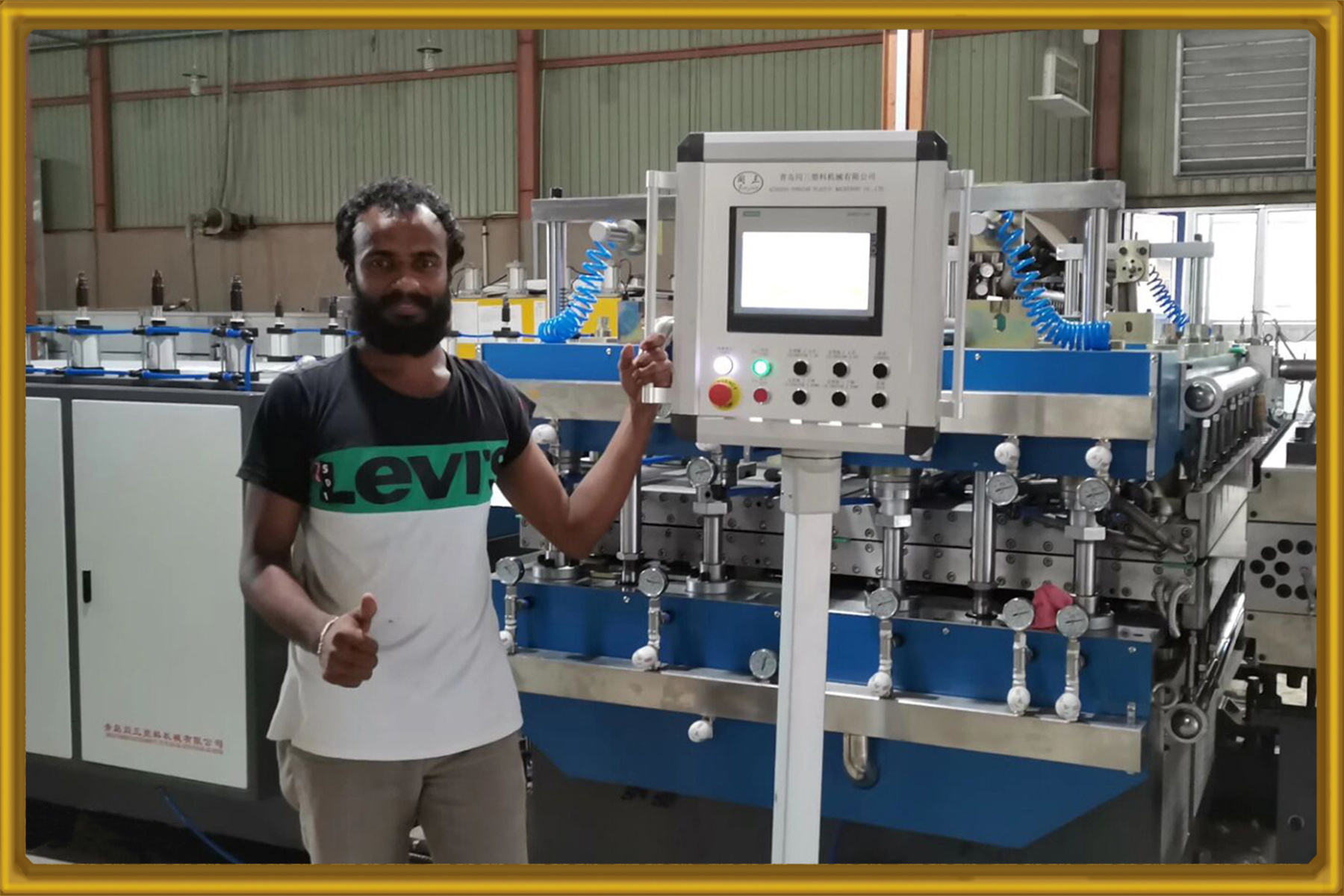

Through online guidance, we have remotely assisted many new customers to successfully complete the installation and operation of the machine in a short time, and produce qualified PP hollow corrugated board.This is even more

commendable in the face of difficult global travel.

Professional engineer online service

Easy operate

Smart machine

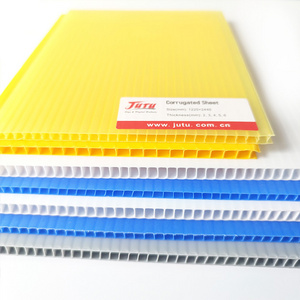

2,High capacity 0-80% Filler (Calcium) PP hollow corrugated sheet making machine

We provide high out production line with professional technology support,and auxiliary machine for package box making machines,such as printing machine,automatic die cutting machine,cartonplast box making machine,welding machine and edge sealing machine.

|

Model

|

PP1400

|

PP1860

|

TS2300

|

TS2600

|

TS-3000

|

|

Extruder

|

SJ110/36

|

120/36

|

SJ120/36

|

120/36

|

SJ-150/36

|

|

Max.Sheet Width

|

1250mm

|

1700mm

|

2150mm

|

2450mm

|

2800mm

|

|

Max Output(kg/h)

|

210-300kg/h

|

280-450kg/h

|

350-550kg/h

|

400-550kg/h

|

450-550kg/h

|

|

Motor Power(KW)

|

90

|

110

|

110-132

|

132-160

|

132-185

|

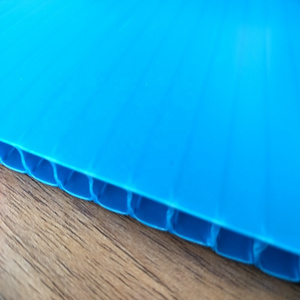

Plastic corrugated pipe application

The plastic hollow sheet is widely used in advertisement, interrior decoration, transportation and package for machinery,

electron, home appliance, medicine, food, glass, agricultural products.

PP hollow corrugated sheet line electrical cabinet

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable

extruding.We have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

PP hollow corrugated sheet mold

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also

differential action of up-down piece guarantee even thickness of the plate

PP hollow corrugated sheet calibrator

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system,

which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

PP hollow corrugated sheet tractor

There are two tractors. The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronize . The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

remove the stress of plate and further improve planeness of the plate.

PP hollow corrugated sheet cutter

Auto Cutting machine for PP hollow sheet machine: Accurate instant length-fixed cutting and automatic up-down discharging system

combined with alloy steel sharp blade realize high quality of cutting.

Perfect service system:

1.We will provide the Feasibility Analysis Report for the wood-plastic project.

2.We will provide the model selection and technical parameter for wood-plastic machinery.

3.We will provide the design for the plant and electric power accounting for the facilities.

4.We will provide the design for wood-plastic formula according to the product requirements.

5.We will provide the technology of wood-plastic product surface treatment

6.We will provide technique training for operator.

7.We will provide solution for the practical problem during the production.

8.We will install and test the machine for free.

9.We will provide turnkey project to customers.