- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

4.3 kN

-

Theoretical Shot Volume(cm³):

-

300 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

165 g

-

Screw Speed (rpm):

-

1 - 2 rpm

-

Screw diameter (mm):

-

28 mm

-

Screw L/D Ratio:

-

12

-

Distance between Tie Bars:

-

450mm

-

Weight (KG):

-

5300 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

TYM-L5068

-

Brand Name:

-

TYM

-

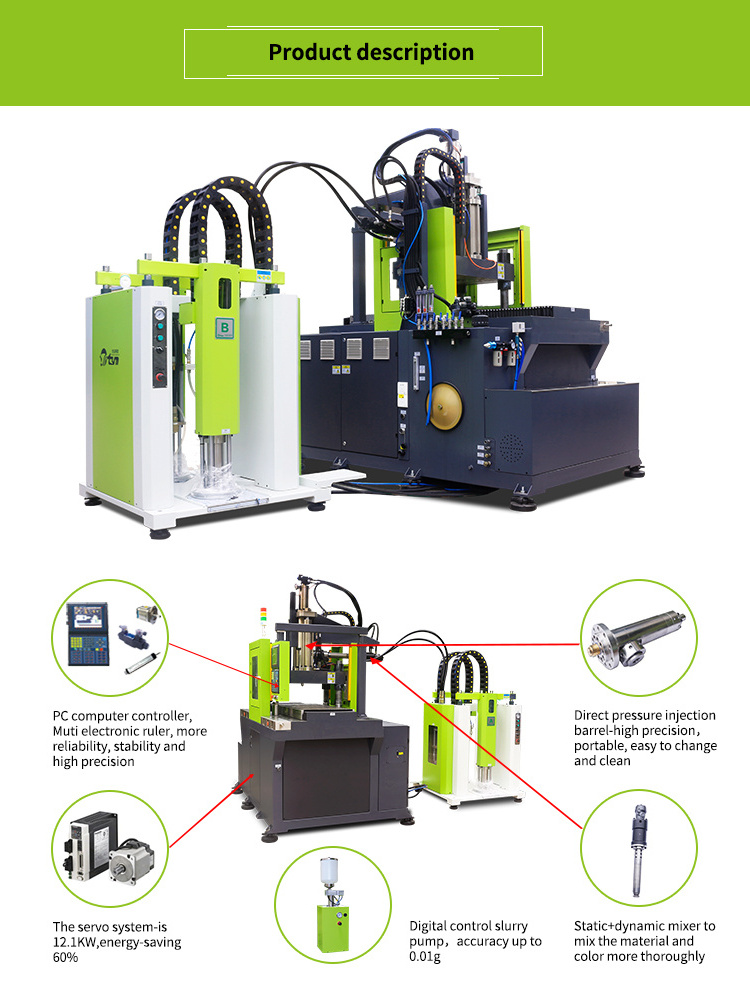

Power (kW):

-

12.1 kW

-

Product name:

-

phone case making machine

-

After-sales Service Provided:

-

Video technical support

-

Injection Rate:

-

30g/s

-

Opening Stroke:

-

250mm-550mm

-

Injection pressure:

-

200kg/cm2

-

Pump pressure:

-

21Mpa

-

Ejection Stroke:

-

150mm

-

templete dimension:

-

600mm *680mm

-

Dimension(L*W*H):

-

2700mm *1750mm * 3600mm

-

Machine weight:

-

6T

-

Marketing Type:

-

New Product 2021

Quick Details

-

Plasticizing Capacity(g/s):

-

60

-

Mold Height(mm):

-

200 - 300 mm

-

Ejector Stroke(mm):

-

150 mm

-

Ejector Force(kN):

-

4.3 kN

-

Theoretical Shot Volume(cm³):

-

300 cm³

-

Injection Rate (g/s):

-

30 g/s

-

Injection Weight (g):

-

165 g

-

Screw Speed (rpm):

-

1 - 2 rpm

-

Screw diameter (mm):

-

28 mm

-

Screw L/D Ratio:

-

12

-

Distance between Tie Bars:

-

450mm

-

Weight (KG):

-

5300 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

550 mm

-

Model Number:

-

TYM-L5068

-

Brand Name:

-

TYM

-

Power (kW):

-

12.1 kW

-

Product name:

-

phone case making machine

-

After-sales Service Provided:

-

Video technical support

-

Injection Rate:

-

30g/s

-

Opening Stroke:

-

250mm-550mm

-

Injection pressure:

-

200kg/cm2

-

Pump pressure:

-

21Mpa

-

Ejection Stroke:

-

150mm

-

templete dimension:

-

600mm *680mm

-

Dimension(L*W*H):

-

2700mm *1750mm * 3600mm

-

Machine weight:

-

6T

-

Marketing Type:

-

New Product 2021

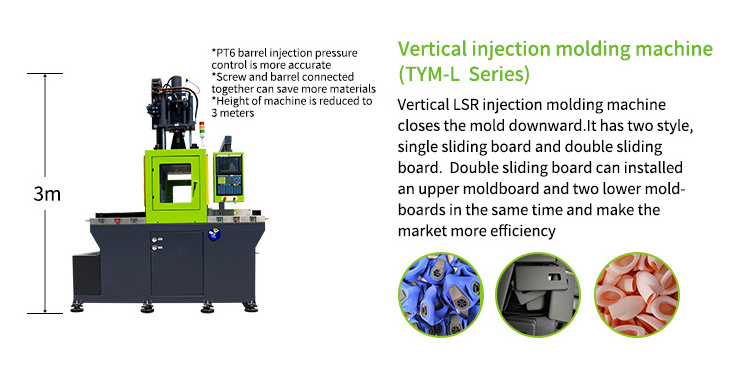

Vertical Liquid Silicone Rubber (LSR) injection molding machine

Closing the mould downward, two kinds of models can be chose – single sliding board and double sliding board. For double sliding board LSR machine, one upper moldboard and two lower moldboards are installed, which improves the production efficiency. The sliding out structure on the machine makes the production more conveniently and more safely. Also the vertical mould opening and closing is more suitable for producing the overmold (inmold) LSR parts which has inserts.

The main feature of the vertical LSR molding machine:

A. Advanced sliding rail structure, which can reduce the oil pollution and make the machine works faster and steadier.

B. Active pin valve-pattern nozzle sealing system, which can guarantee the injection more accurately.

C. Meet the requirements on multi-station production.

D. High-performance servo motor system is installed, which can guarantee the machine work more accurately and more energy-saving .

Mechanical Characteristics for TYM-L 5 0 5 8-2

|

TYM-L 5 0 5 8 Vertical LSR injection molding machine |

|

|

Injection Unit |

|

|

Shot Volume |

165 g |

|

Injection Rate |

30 g/s |

|

Injection Pressure |

19.6 T |

|

Clamping Unit |

|

|

Clamping Force |

130 T |

|

Opening Stroke |

250-550 mm |

|

Tie-Bars Pace |

5 00* 5 80 mm |

|

Ejection Force |

7.8 T |

|

Ejection Stroke |

150 mm |

|

Others |

|

|

Pump Pressure |

21 Mpa |

|

Motor Power |

12.1 KW |

|

Heater Power |

9 KW |

|

Mould Orientation Ring Diameter |

Φ 100 mm |

|

Machine Weight |

6 T |

|

Machine Dimension |

2.5*1.6*3.6 m |