- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Power:

-

10W

-

Warranty:

-

1 Year

-

Width or Diameter:

-

30mm

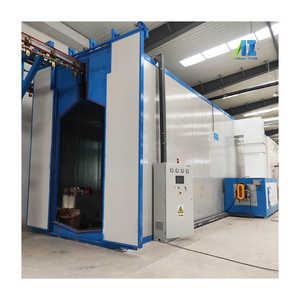

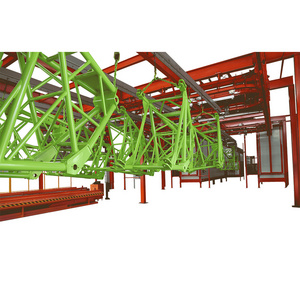

Chain overhead hanging Trolley conveying tension device for powder coating curing oven conveyor

Take up device

The tensioning device is used to tighten the tail shaft, and its function is to:

1. Keep the conveyor chain running in a certain tension state, and eliminate the phenomenon of jumping, vibration and abnormal noise when the chain conveyor is running due to the chain relaxation.

2. When the conveying chain is extended due to wear, it shall be compensated by the tensioning device to maintain the pre tightness of the chain. There are two methods of tension device: Hammer tension and spring tension. The tension device should be installed in the place with the minimum tension in the chain conveyor line.

XT80, 160 single wheel tension device is a device to ensure chain tension, compensate installation error and chain elongation under the action of tension, wear and expansion caused by temperature difference, ensure that there is an initial tension at the winding point of the drive device, and eliminate negative production in the whole line. The tensioning devices of XT100 and XT160 common suspension conveyors are of the hammer type, which can automatically adjust the chain tension depending on the weight of the counterweight plate on the device, which can be divided into two types: single wheel tension and double wheel tension. The tension should be placed in the place with less tension, which is generally arranged in the lower place near the rear of the transmission device. After being close to the tension, there should be no large load falling slope section.

| Speciality: |

1. Efficient shockproof

2. High quality steel with good rust resistance and acid resistance

3. Round arch design

4. Wide range of applications for all kinds of walking automatic lines

5. Various type and sufficient storage

Providing customized services!